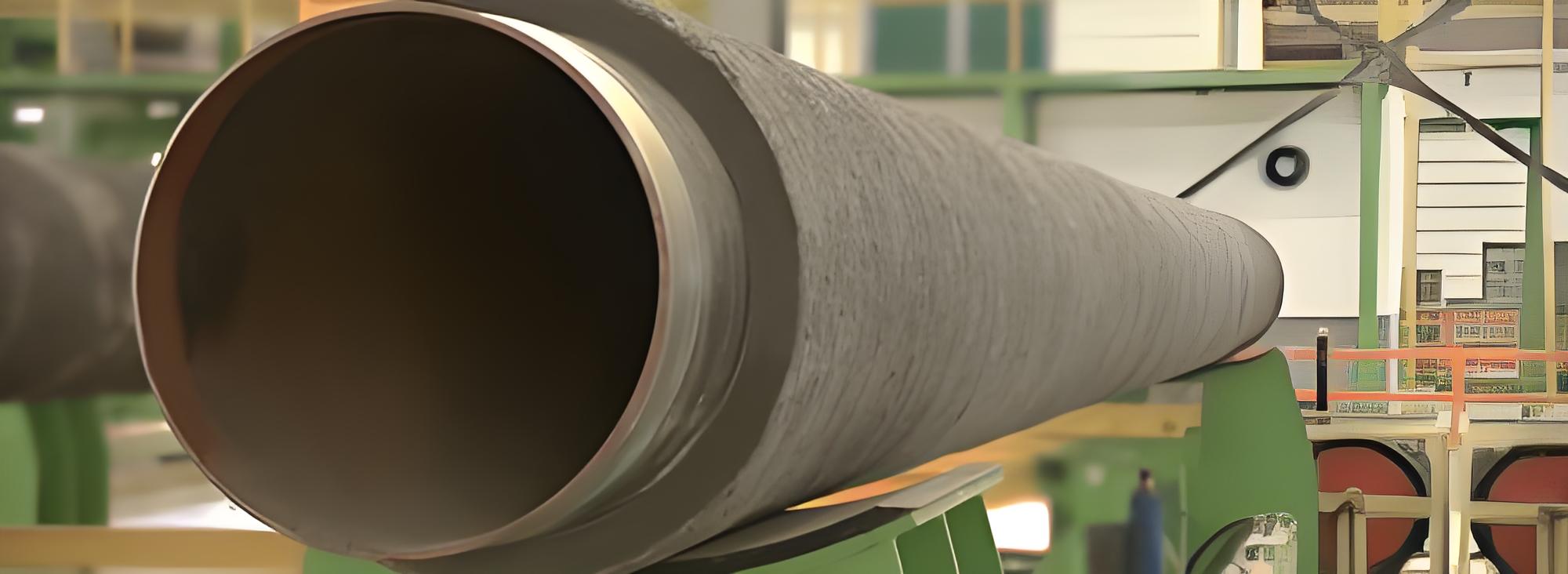

2LPE / 2LPP Coated Pipe

2LPE / 2LPP Coated Pipe Overview

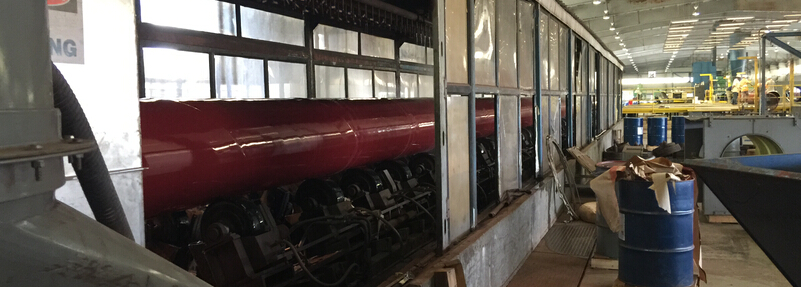

2LPE (Two-Layer Polyethylene) and 2LPP (Two-Layer Polypropylene) coatings are advanced protective coatings used for steel pipes to guard against corrosion and mechanical damage. These coatings are widely applied in industries such as oil and gas, water supply, and chemical processing due to their effectiveness and durability.

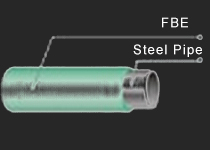

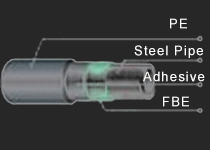

Structure of 2LPE and 2LPP Coatings

Both 2LPE and 2LPP coatings consist of two layers:

- First Layer (Fusion Bonded Epoxy – FBE)

- Provides primary corrosion protection by creating a barrier against moisture, oxygen, and other corrosive elements.

- Applied by spraying melted epoxy powder onto the pre-heated pipe surface, which then fuses and cures.

- Second Layer (Polyethylene or Polypropylene)

- 2LPE: Uses polyethylene as the top layer.

- 2LPP: Uses polypropylene as the top layer.

- This outer layer offers mechanical protection against impacts, abrasions, and physical damages.

Key Features of 2LPE / 2LPP Coated Pipes

- Corrosion Resistance:

- The FBE layer provides excellent adhesion to the steel pipe and superior resistance to corrosion.

- The outer polyethylene or polypropylene layer further enhances the corrosion resistance.

- Mechanical Protection:

- The outer layer of polyethylene or polypropylene protects the pipe from physical damage during handling, transportation, and installation.

- Adhesion:

- The fusion bonded epoxy ensures strong adhesion to the steel substrate, while the polyethylene or polypropylene layer adheres well to the FBE layer.

- Chemical Resistance:

- Both coatings offer resistance to a variety of chemicals, making them suitable for pipelines transporting different substances.

- Temperature Range:

- 2LPE: Suitable for environments with moderate temperatures, typically up to 60°C.

- 2LPP: Can withstand higher temperatures, usually up to 90°C, making it suitable for hotter environments.

Minimum Layer Thickness of 2LPP Coated Pipe

- Fusion Bonded Epoxy (FBE) Layer: Typically around 100 to 200 microns.

- Polypropylene (PP) Layer: Generally around 1.8 to 3.0 mm.

The exact thickness can vary depending on specific project requirements and standards.

| Commodity | 2LPE/3LPE/3PP/ HDPE COATED Carbon Steel Pipeline |

| Outer diameter | 21mm-2650mm |

| Wall thickness | 0.5-45mm |

| Length | 5m-14m or as customers’ requirements |

| End finish | Plain/ beveled ends or threaded with sockets/coupling and plastic caps. |

| Material | Q235 Q345 St37 St52 St37-2 10# 20# 16Mn or API 5L X42/X46/X52/X60/X70 |

| External Coating | |

| Coating type | Coating Standard |

| 3LPE/3LPP | DIN30670-1991,CAN/CSA Z245,21-2010,ISO21809-1-2009 SY/T 0413-2002,GB/T23257-2009 |

| 2LPE/2LPP | SY/T 0315-2002,GB/T23257-2009,ISO21809-1-2009 |

| FBE(Fusion-bond epoxy) | SY/T 0315-2005,AWWA C213-2001,CAN/CSAZ245.20-2010,ISO218909-2-2007,API RP5L9-2001 |

| Bitumen coating Enamel &Tape hot-applied |

BS534-1990,AWWA203-2002,AWWA214-2000 |

| Liquid epoxy coating | AWWWA C210-2007 |

| Polyurethane insulated coating | SY/T0415-1996,CJ/T114-2000.EN253-1994 |

| Internal Coating | |

| Liquid Epoxy Coating | AWWAC210-2007 |

| FBE | AWWAC213-2001 |

| Cement Mortar Lining | BS534-1990,AWWA C205-2001 |

| Bitumen Coating | BS534-1990 |

Applications

2LPE and 2LPP coated pipes are used in various applications, including:

- Oil and Gas Industry:

- Transporting crude oil, natural gas, and other petroleum products.

- Water Supply Systems:

- Long-distance water pipelines for potable and industrial water.

- Chemical Processing:

- Pipelines carrying corrosive chemicals and industrial fluids.

- Infrastructure Projects:

- Used in construction projects requiring durable and long-lasting pipeline solutions.

Advantages of 2LPE / 2LPP Coatings

- Long Service Life:

- Enhanced protection against corrosion and physical damages contributes to a longer service life of the pipeline.

- Cost-Effective:

- Reduces maintenance and repair costs due to its robust protective properties.

- Environmentally Friendly:

- Reduces the risk of leaks and spills, protecting the environment.

- Ease of Installation:

- The coatings are designed to withstand the rigors of installation procedures, ensuring minimal damage and easy handling.

Standards and Specifications

2LPE and 2LPP coatings are manufactured according to various international standards, such as:

- ISO 21809:

- Petroleum and natural gas industries — External coatings for buried or submerged pipelines used in pipeline transportation systems.

- DIN 30670:

- Polyethylene coatings for steel pipes and fittings.

- DIN 30678:

- Polypropylene coatings for steel pipes and fittings.

History of the Development of PP Materials

- Early Development:

- Polypropylene was first polymerized by German chemist Karl Rehn and Italian chemist Giulio Natta in 1954.

- Natta and his team developed a method to produce isotactic polypropylene, which led to commercial production.

- Commercial Production:

- The first commercial production of polypropylene began in the late 1950s.

- The material quickly gained popularity for its versatility, strength, and chemical resistance.

- Advancements in Applications:

- Over the decades, advancements in polymer science have improved the properties of polypropylene, making it suitable for a wide range of applications, including coatings for pipelines.

- Introduction to Pipeline Coatings:

- Polypropylene’s excellent mechanical and thermal properties made it an ideal candidate for pipeline coatings.

- The development of multi-layer coating systems, such as 2LPP and 3LPP, has further enhanced the performance of pipelines in demanding environments.

- Modern Use:

- Today, polypropylene coatings are widely used in various industries, providing reliable protection for pipelines and other structures in harsh conditions.

| Operating Temperature(℃) | Expected Minimum Service Life (Year) |

|---|---|

| 23 | 50 |

| 60 | 50 |

| 80 | 30 |

| 90 | 16 |

| 100 | 8 |

| If the coatings are used at alternating temperatures, their expected service life should be inferred from the values made above. | |

| Nominal Diameter | Minimum Coating Thickness (mm) |

|---|---|

| Less than or equal to 100 | 1.8 |

| 125-250 | 2 |

| 300-500 | 2.2 |

| 600 or more | 2.5 |

As part of the impact test, a ball with a diameter of 25mm is dropped on the 2LPP coated pipe sample, which must be supported so that it does not collapse under the force of the dropping hammer. The landing altitude should be approximately 1 m, and the temperature should be 0 °C during the test. It is required that the impact energy E be equal to the coating thickness (5W) J/mm, with a permissible limit of 5 percent of the total impact energy. The radius of curvature of the tube is represented by this coefficient. The impact energy can be reduced by lowering the weight of the drop hammer or raising the height of the drop to a lower velocity.

| Nominal Diameter | J/mm |

|---|---|

| Less than or equal to DN65 | 0.7 |

| DN80 – 150 | 0.85 |

| Greater than or equal to DN200 | 1 |

Conclusion

2LPE and 2LPP coated pipes provide robust protection against corrosion and mechanical damage, making them ideal for a wide range of industrial applications. The combination of fusion bonded epoxy and polyethylene or polypropylene layers ensures long-lasting performance and reliability. By selecting the appropriate coating (2LPE for moderate temperatures and 2LPP for higher temperatures), industries can ensure optimal protection and longevity of their pipeline systems.