UL List Steel Pipe

Size Range and Application

Size:ODΦ21.3mm-323.9mm WT:2.77-10.31mm(SCH40)

Usage:Used for sprinklers fire protection service

Standard and material:ASTM A53 GR.B

Type:seamless or welded as the construction design

As the leading manufacturer and supplier of fire fighting pipe, we have UL certificate for sprinkler steel pipes and fittings. With the most advanced pipe processing technology and equipment, we are specialized in providing more convenient & reliable fire fighting products.

| Standard and material |

(Chemical Composition) |

(Mechanical Properties) |

| C |

Mn |

P |

S |

Cu |

NI |

Cr |

Mo |

V |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

| ASTM A53 GR.B |

≤0.30 |

≤1.20 |

0.05 |

0.045 |

0.40 |

0.40 |

0.40 |

0.15 |

0.08 |

≥415 |

≥240 |

Pipe ends Finished: Rolled Groove end , Slotted end.

The end is available for slotted accessorices connected, such as slotted clamp, slotted elbow and tee.

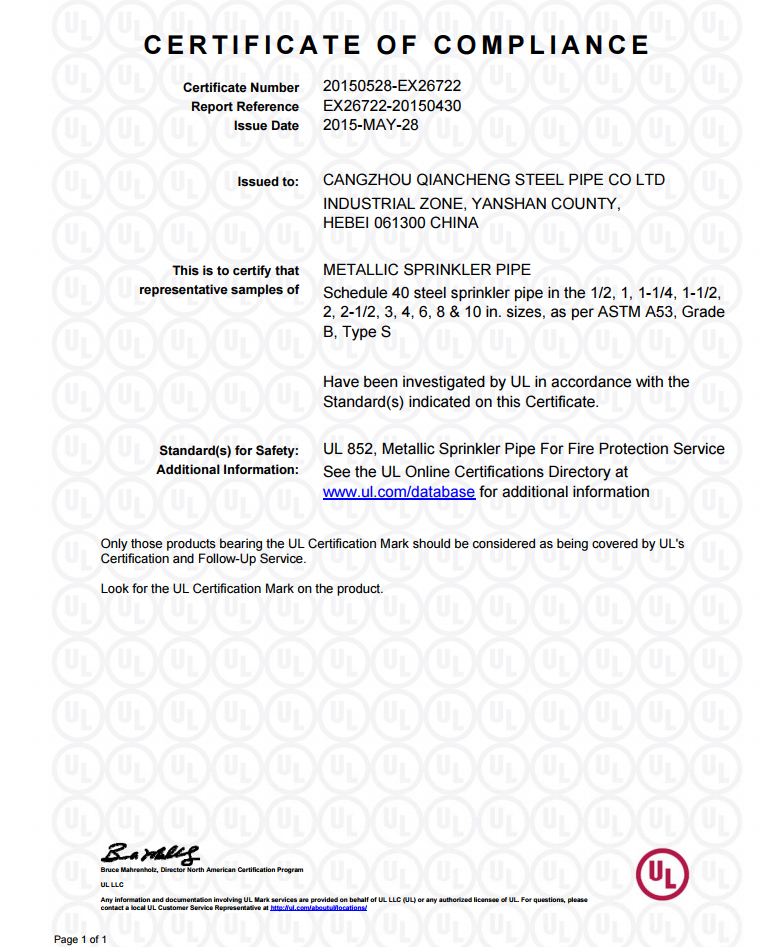

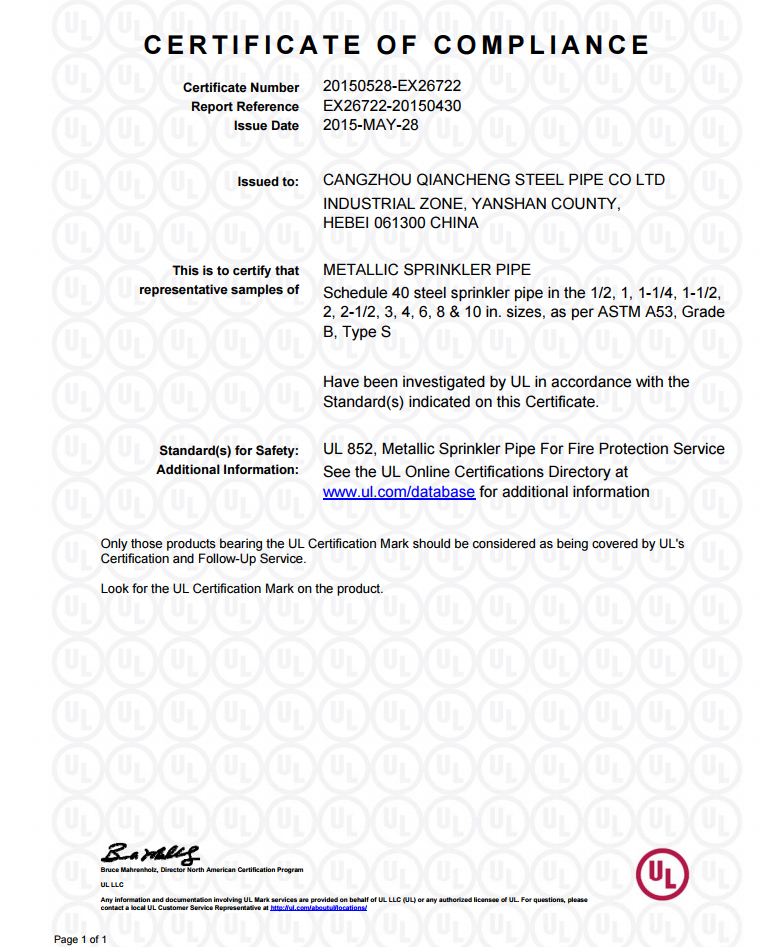

Certificate

Fire Sprinkler Pipe is UL and FM certificate Approved

1. Factory

The factory is in Tianjin city China

2. Weights

The weight shall not vary more than +/-5% from that prescribed.

3. Diameter

For pipe NPS 1/2-11⁄2 (DN 40) , the outside diameter at any point shall not vary more than 1⁄64 inch (0.4 mm) over nor more than 1⁄32 inch (0.8 mm) .

For pipe NPS 2 (DN 50)-10 (DN250), the outside diameter shall not vary more than +/-1 % .

4. Thickness

The minimum wall thickness at any point shall not vary more than 12.5 % under the nominal wall thickness.

5. Sample Service

Free Sample, will charge INT’L Courier

Related Posts

Multifunctional ms erw black round tube

ERW BLACK Pipes. Electric Resistance Welded (ERW) Pipes are manufactured from Hot Rolled Coils / Slits. All the incoming coils are verified based on the test certificate received from steel mill for their chemistry and mechanical properties. ERW pipe is cold-formed into a cylindrical shape, not hot-formed.

ERW black round steel pipe

Seamless pipe is manufactured by extruding the metal to the desired length; therefore ERW pipe have a welded joint in its cross-section, while seamless pipe does not have any joint in its cross-section through-out its length. In Seamless pipe, there are no welding or joints and is manufactured from solid round billets.

Dimensions and weights of seamless Pipe according to standards

The 3 elements of pipe dimension Dimension Standards of carbon and stainless steel pipe (ASME B36.10M & B36.19M) Pipe Size Schedule (Schedule 40 & 80 steel pipe means) Means of Nominal Pipe Size (NPS) and Nominal Diameter (DN) Steel Pipe Dimension Chart (Size chart) Pipe Weight Class Schedule (WGT)

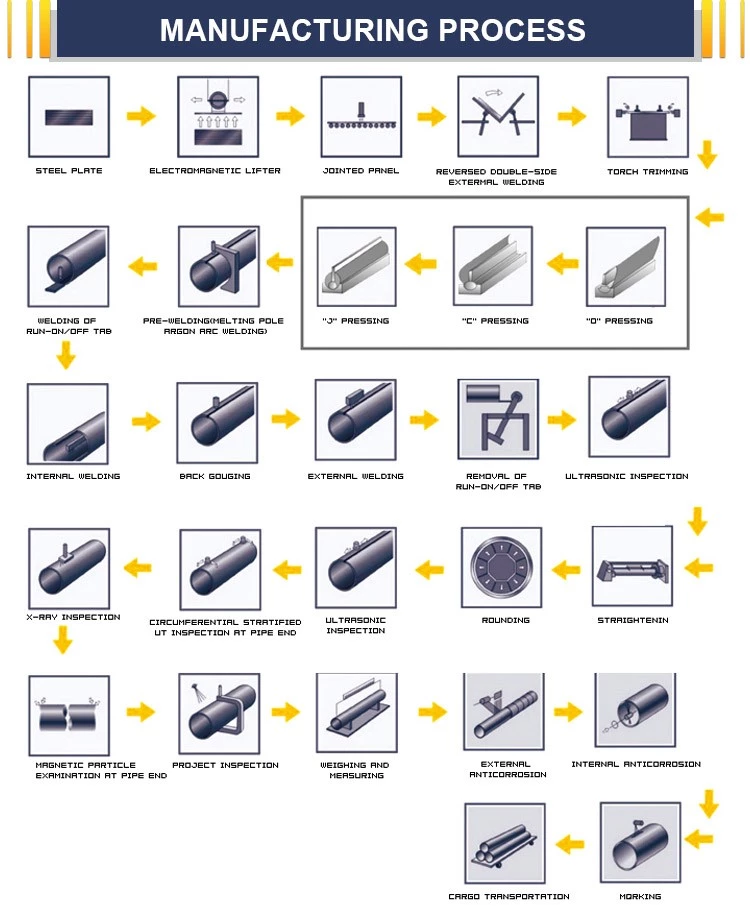

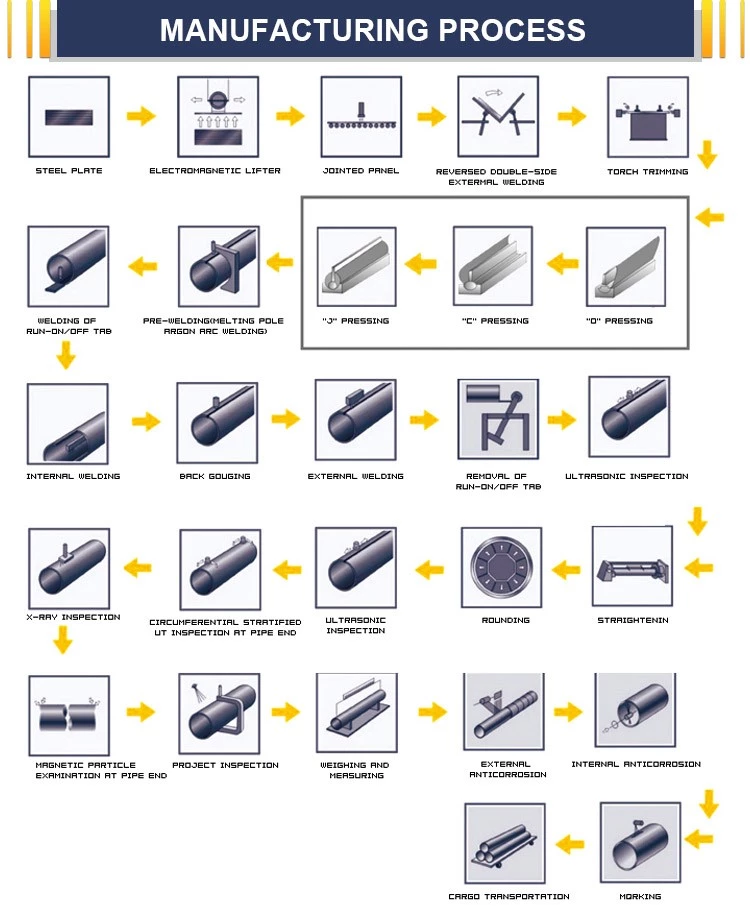

Steel Pipe and Manufacturing Processes

Seamless pipes are manufactured using a piercing process, where a solid billet is heated and pierced to form a hollow tube. Welded pipes, on the other hand, are formed by joining two edges of steel plates or coils using various welding techniques.

Spring Hanger and Support

Type A- Used where ample head room is available. Specific elevation is desirable. Type B- Used where headroom is limited. Head attachment is a single lug. Type C- Used where headroom is limited. Head attachment is side by side lugs