Manufacturing Process

Steel Pipe Solutions, Design & Manufacture

manufacture Research

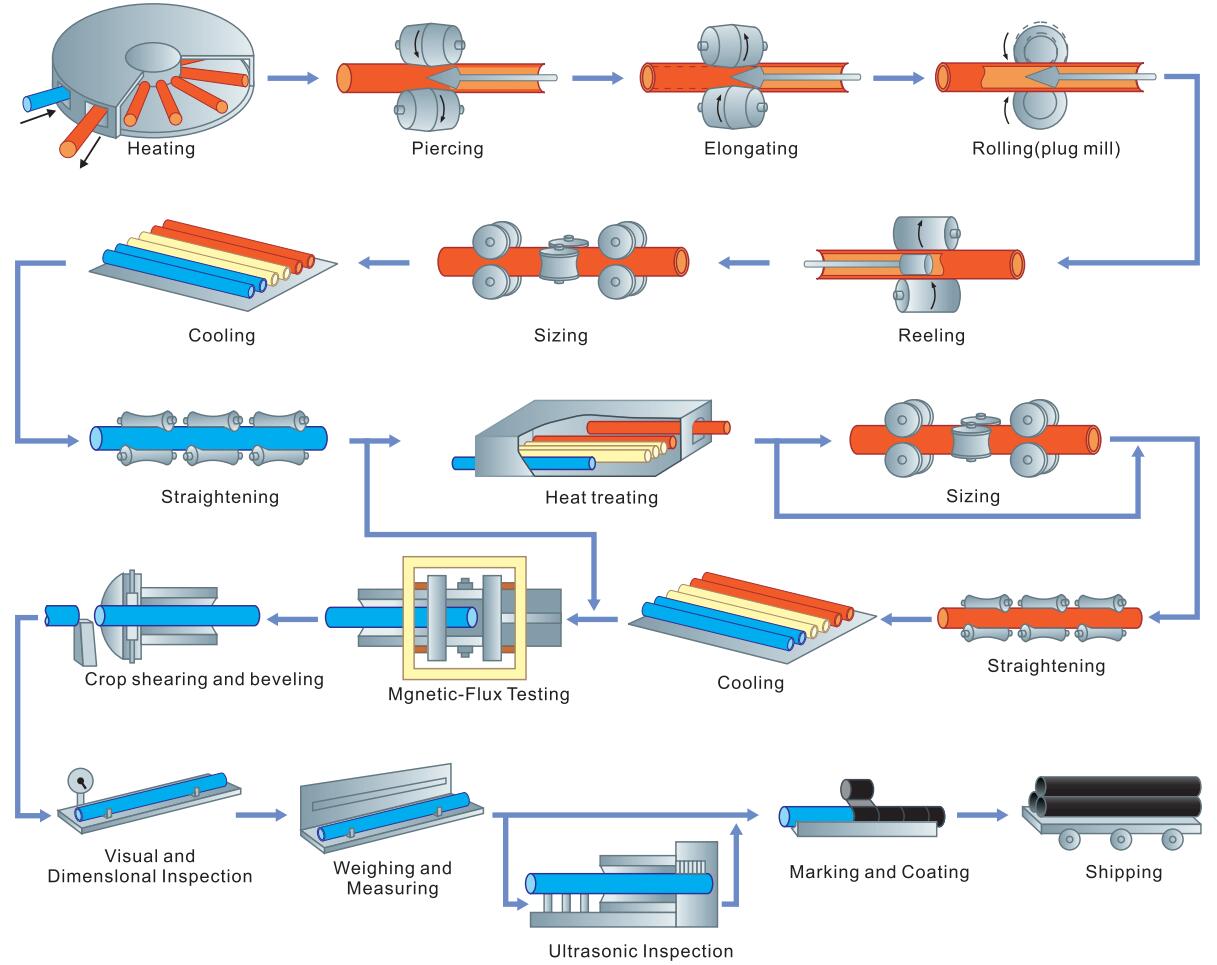

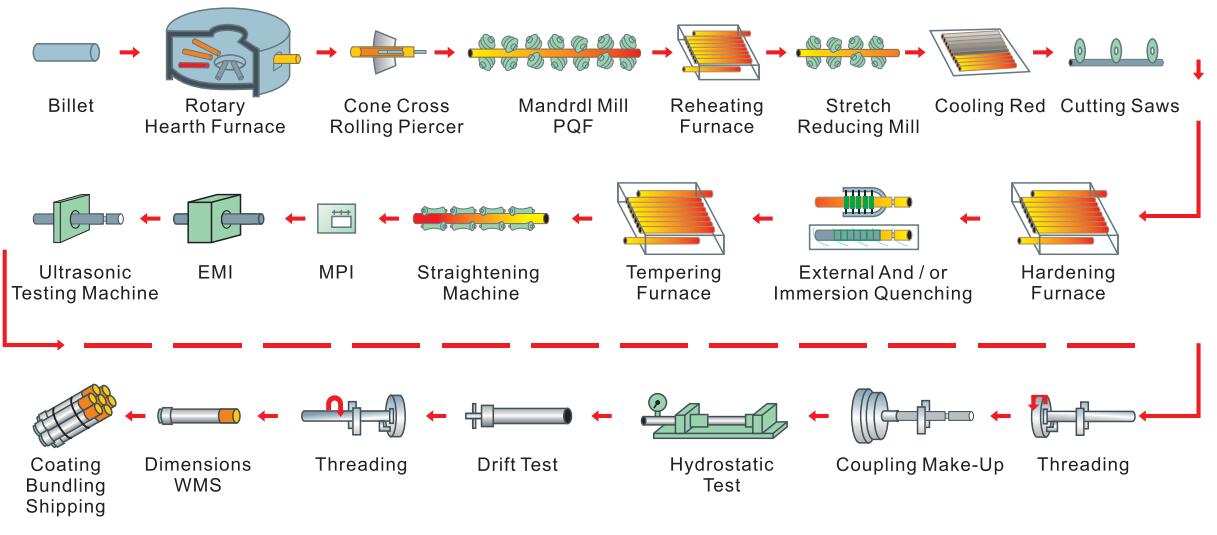

Seamless steel pipe manufacturing is a complex process that involves several stages to produce high-quality pipes without any welded seams. Here is a detailed overview of the typical seamless steel pipe manufacturing process:

Leverage agile frameworks to provide a robust synopsis for high level overviews. Iterative approaches to corporate strategy foster collaborative thinking.

Billet Preparation: The process begins with the preparation of raw materials, usually in the form of solid cylindrical steel billets. These billets undergo thorough inspection for quality, including checks for chemical composition, surface defects, and dimensions.

Heating: The billets are then heated in a furnace to a specific temperature range. This heating process is crucial to make the steel malleable and ready for further processing.

Piercing: Once the billets reach the desired temperature, they are pierced by a piercing mill or a rotary piercing machine. This operation creates a hollow shell known as a “bloom” or “hollow” in the center of the billet.

Rolling: The pierced billet is then rolled by a mandrel mill or a plug mill. In the mandrel mill process, the hollow shell is elongated and reduced in diameter by a series of rolling stands using a mandrel to support the inner wall. In the plug mill process, a heated cylindrical plug is inserted into the hollow shell, and both are rolled together to reduce the diameter and increase the length.

Sizing: After the initial rolling, the pipe is passed through a sizing mill to achieve the desired outer diameter and wall thickness. This process involves multiple stands that gradually reduce the pipe’s size and ensure its dimensional accuracy.

Heat Treatment: Heat treatment is often performed to enhance the mechanical properties of the seamless steel pipe. This process may include annealing, normalizing, or quenching and tempering, depending on the specific requirements of the pipe and its intended application.

Straightening: The pipe is then straightened using a straightening machine to ensure its straightness and eliminate any residual curvature.

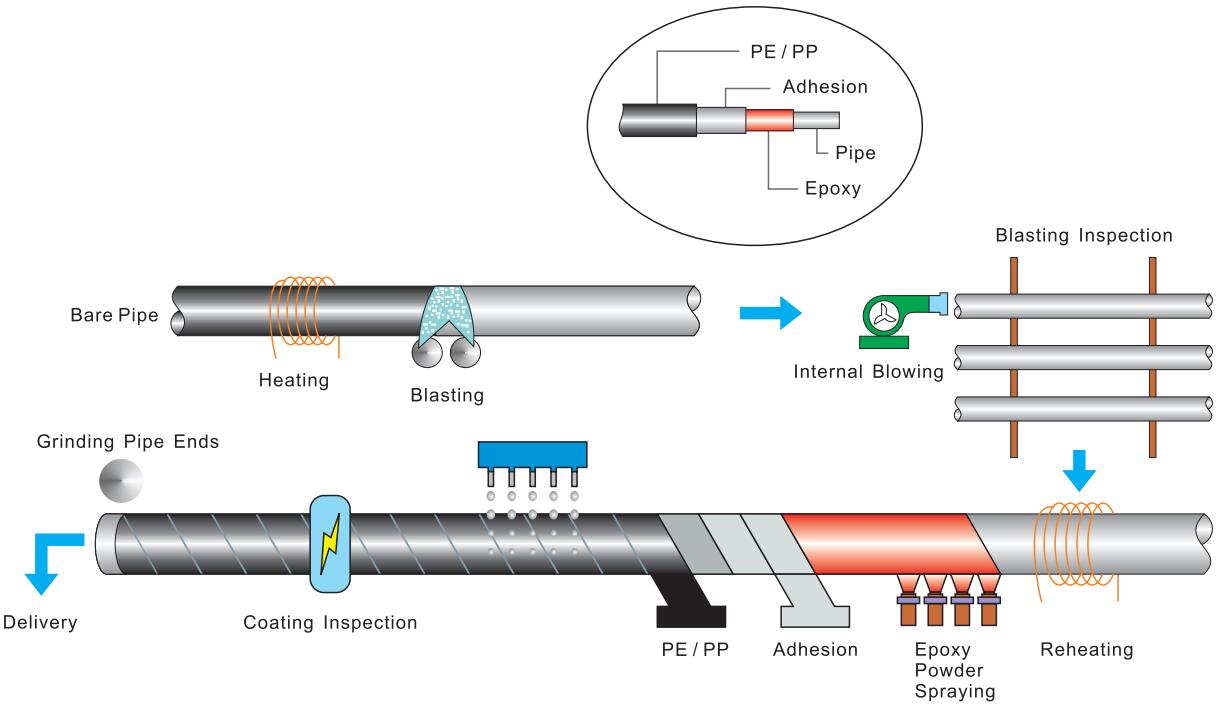

Cutting and Finishing: The seamless pipe is cut to the desired length using either a flying saw or a rotary disc cutter. The cut ends are then deburred and inspected for any surface defects. The pipe may undergo additional finishing processes, such as surface treatment or coating, to enhance its corrosion resistance.

Non-Destructive Testing: To ensure the quality of the seamless steel pipe, non-destructive testing methods such as ultrasonic testing, eddy current testing, or magnetic particle inspection are performed. These tests detect any internal or surface defects that may affect the pipe’s integrity.

Final Inspection and Packaging: The finished seamless pipes undergo a final inspection to verify their compliance with the required specifications and standards. They are then carefully packaged, usually in bundles or crates, to protect them during transportation and storage.