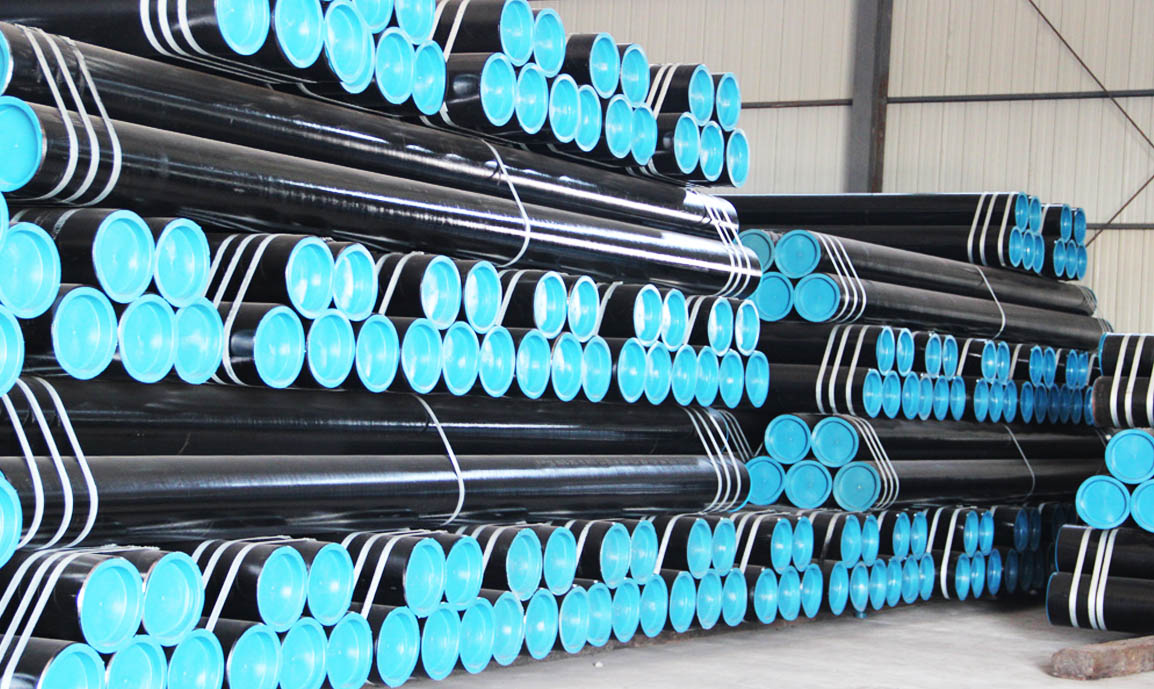

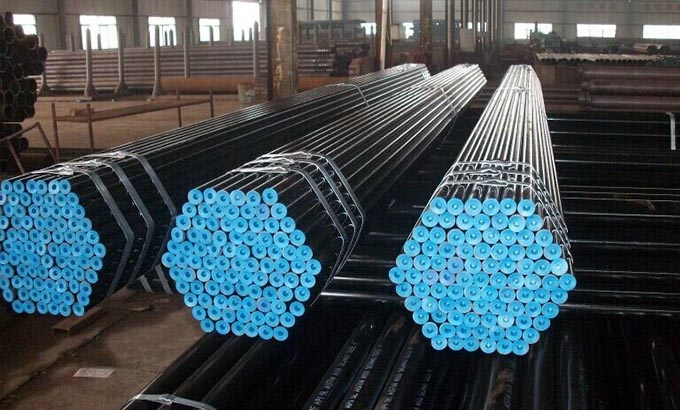

Seamless Steel Fluid Pipe

Seamless Steel Fluid Pipe: A Detailed Overview

Seamless steel fluid pipes are essential for transporting fluids safely and efficiently in various industrial applications. These pipes are preferred due to their strength, durability, and ability to withstand high pressures and temperatures without failure. This guide will cover the characteristics, manufacturing process, materials, standards, and typical applications of seamless steel fluid pipes.

Characteristics of Seamless Steel Fluid Pipes

- High Strength: Seamless pipes are known for their high tensile strength, making them suitable for high-pressure applications.

- Durability: These pipes have a long service life due to their resistance to wear and tear.

- Corrosion Resistance: Seamless pipes are often made from materials that resist corrosion, making them ideal for transporting various fluids.

- Smooth Interior Surface: The absence of seams results in a smoother internal surface, which reduces friction and improves fluid flow.

- Leak-Free: The seamless construction minimizes the risk of leaks, ensuring the safe transport of fluids.

Manufacturing Process

Seamless steel fluid pipes are produced through a series of steps:

- Billet Preparation: A solid cylindrical billet is heated to a high temperature.

- Piercing: The heated billet is pierced to create a hollow tube.

- Elongation: The hollow tube is elongated and rolled to the desired thickness and diameter.

- Sizing: The pipe is passed through sizing rolls to achieve the precise dimensions.

- Cooling: The pipe is cooled in a controlled manner to ensure material properties are maintained.

- Finishing: The pipe undergoes various finishing processes, such as straightening, cutting, and surface treatment.

Materials

Seamless steel fluid pipes are made from various materials to suit different applications:

- Carbon Steel: Commonly used for its strength and affordability. Examples include ASTM A106 Gr.B and ASTM A53 Gr.B.

- Alloy Steel: Provides enhanced mechanical properties, such as increased strength and resistance to corrosion and oxidation. Examples include ASTM A335 P11 and P22.

- Stainless Steel: Known for its excellent corrosion resistance and durability. Examples include ASTM A312 TP304 and TP316.

Standards

Seamless steel fluid pipes must comply with international standards to ensure quality and performance. Some key standards include:

- ASTM Standards:

- ASTM A106: Standard specification for seamless carbon steel pipe for high-temperature service.

- ASTM A53: Standard specification for pipe, steel, black and hot-dipped, zinc-coated, welded and seamless.

- ASTM A335: Standard specification for seamless ferritic alloy-steel pipe for high-temperature service.

- ASTM A312: Standard specification for seamless, welded, and heavily cold-worked austenitic stainless steel pipes.

- ASME Standards:

- ASME SA106: Corresponds to ASTM A106 for seamless carbon steel pipes.

- ASME SA335: Corresponds to ASTM A335 for seamless alloy steel pipes.

- EN Standards:

- EN 10216: Seamless steel tubes for pressure purposes.

- DIN Standards:

- DIN 1629: Seamless circular unalloyed steel tubes.

Applications

Seamless steel fluid pipes are used in various industries due to their versatility and reliability:

- Oil and Gas: Transporting crude oil, natural gas, and refined products under high pressures.

- Petrochemical: Conveying chemicals and other fluids in processing plants.

- Power Generation: Used in steam boilers and heat exchangers.

- Automotive: Fuel lines, hydraulic systems, and other fluid transport applications.

- Construction: Plumbing and heating systems, as well as structural applications.

- Water Treatment: Conveying potable water, wastewater, and other fluids.

Key Properties

Seamless steel fluid pipes must exhibit certain properties to perform effectively in their applications:

- Pressure Resistance: Ability to withstand high internal pressures without bursting.

- Temperature Resistance: Maintain structural integrity at high and low temperatures.

- Corrosion Resistance: Resist corrosion from fluids and environmental exposure.

- Mechanical Strength: High tensile and yield strength to handle mechanical stresses.

- Dimensional Accuracy: Precise dimensions to ensure proper fitting and flow efficiency.

Seamless Steel Fluid Pipe: Chemical Composition and Mechanical Properties