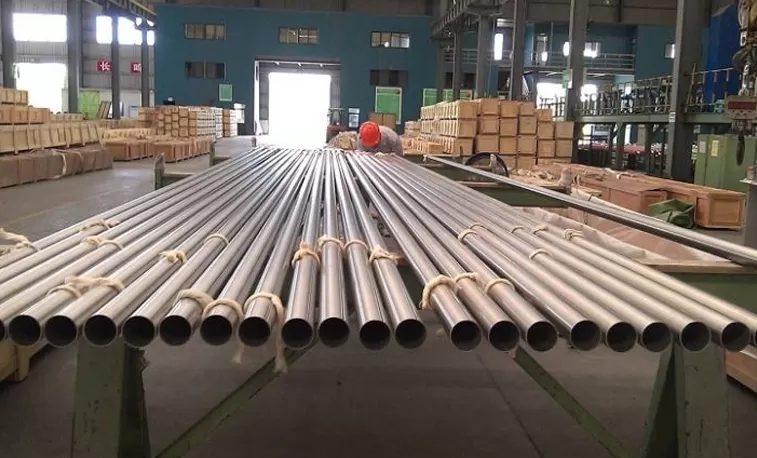

Nickel 201 Steel Tube (UNS N02201)

Nickel 201 Steel Tube (UNS N02201)

Nickel 201, also known as UNS N02201, is a commercially pure wrought nickel with properties similar to Nickel 200 but with a lower carbon content. This lower carbon content makes Nickel 201 less susceptible to embrittlement by intergranular carbon at temperatures above 315°C (600°F), making it suitable for applications involving higher temperatures.

Chemical Composition

The typical chemical composition of Nickel 201 is as follows:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 99.0 min |

| Copper (Cu) | 0.25 max |

| Iron (Fe) | 0.40 max |

| Manganese (Mn) | 0.35 max |

| Silicon (Si) | 0.35 max |

| Carbon (C) | 0.02 max |

| Sulfur (S) | 0.01 max |

Mechanical Properties

Nickel 201 exhibits good mechanical properties over a wide range of temperatures:

- Tensile Strength: 365 MPa (53 ksi) min

- Yield Strength (0.2% offset): 83 MPa (12 ksi) min

- Elongation: 40% min

- Hardness: 65 HRB max

Physical Properties

- Density: 8.89 g/cm³ (0.321 lb/in³)

- Melting Point: 1435°C (2615°F)

- Specific Heat Capacity: 0.11 cal/g·°C (at 20°C)

- Thermal Conductivity: 90.7 W/m·K (at 20°C)

- Electrical Resistivity: 0.096 µΩ·m (at 20°C)

- Modulus of Elasticity: 207 GPa (at 20°C)

- Poisson’s Ratio: 0.31 (at 20°C)

Industries Predominantly Using Nickel 201

- Chemical Processing:

- Manufacturing and handling of sodium hydroxide, particularly at elevated temperatures.

- Production of caustic soda, hydrochloric acid, and other chemicals.

- Electronics:

- Components such as anodes, cathodes, and battery components due to its excellent electrical conductivity.

- Aerospace and Defense:

- Parts requiring resistance to corrosion and good mechanical properties at elevated temperatures.

- Food Processing:

- Equipment and machinery due to its resistance to food acids and alkalies.

Typical Manufacturing Specifications

- ASTM B161: Specification for Nickel Seamless Pipe and Tube

- ASTM B163: Specification for Seamless Nickel and Nickel Alloy Condenser and Heat Exchanger Tubes

- ASTM B725: Specification for Welded Nickel (UNS N02200/UNS N02201) and Nickel-Copper Alloy (UNS N04400) Pipe

- ASME SB161/SB163/SB725: Standards for nickel alloy seamless and welded pipe and tube

Available Tube Product Forms

- Seamless Tubing

- Welded Tubing

- Straight Lengths

- Coiled Tubing

Typical Applications

- Chemical Processing:

- Equipment and piping systems for handling caustic alkalis such as sodium hydroxide.

- Acid production and handling equipment.

- Electronics:

- Components in electronic applications requiring high electrical conductivity.

- Aerospace and Defense:

- Components exposed to corrosive environments and high temperatures.

- Food Processing:

- Equipment and storage vessels for food and beverage industries.

Welding and Fabrication Characteristics

Welding

- Weldability:

- Nickel 201 can be welded using conventional welding methods such as Gas Tungsten Arc Welding (GTAW/TIG), Gas Metal Arc Welding (GMAW/MIG), and Shielded Metal Arc Welding (SMAW).

- Filler Metals: Typically, matching composition filler metals such as ERNi-1 are used.

- Preheating and Post-Weld Heat Treatment (PWHT):

- Preheating: Generally not required. However, cleanliness is crucial to prevent contamination.

- PWHT: Not typically required for Nickel 201, but can be performed to relieve stresses if necessary.

- Weld Defects and How to Avoid Them:

- Porosity: Ensure clean surfaces and proper shielding gases to minimize porosity.

- Cracking: Nickel 201 is generally resistant to cracking, but control welding parameters to avoid solidification cracking.

Fabrication

- Machining:

- General: Nickel 201 is relatively easy to machine, especially compared to other high-nickel alloys. It can be machined using standard techniques.

- Coolants: Use water-based coolants to reduce heat and friction, thereby extending tool life and improving surface finish.

- Tooling: High-speed steel tools can be used, but carbide tools are recommended for better performance and longer tool life.

- Forming:

- Cold Forming: Nickel 201 can be cold-formed using standard methods. It has excellent ductility, allowing for significant deformation without cracking.

- Hot Forming: Hot forming is typically conducted at temperatures between 650°C and 1230°C (1200°F and 2250°F). Proper temperature control is necessary to prevent grain growth and maintain mechanical properties.

- Heat Treatments:

- Annealing: Annealing is performed to soften the material and relieve stress. For Nickel 201, annealing temperatures range from 705°C to 925°C (1300°F to 1700°F), followed by air cooling.

- Stress Relieving: Stress relieving can be performed at temperatures around 480°C to 750°C (900°F to 1380°F) for 1-2 hours, followed by air cooling.

- Surface Cleaning:

- Pickling: Use a pickling solution of sulfuric acid or nitric acid to remove oxides and scale formed during heat treatment or welding.

- Mechanical Cleaning: Grinding and brushing are effective for removing surface contaminants, but care should be taken to avoid embedding iron particles, which could lead to corrosion.

Best Practices for Welding and Fabrication

- Cleanliness: Maintain a clean work environment to prevent contamination. Contaminants such as sulfur, phosphorus, lead, and zinc can lead to weld defects and corrosion issues.

- Tooling: Use dedicated tools for Nickel 201 to avoid cross-contamination from other metals.

- Controlled Environment: Whenever possible, perform welding and fabrication in a controlled environment to minimize the introduction of impurities.

- Training: Ensure that welders and fabricators are specifically trained for handling high-nickel alloys to achieve the best results.

Conclusion

Nickel 201 (UNS N02201) is a versatile material known for its excellent corrosion resistance, good mechanical properties, and high thermal and electrical conductivity. It is suitable for a wide range of applications, especially in chemical processing, electronics, aerospace, and food processing industries. By adhering to best practices in welding and fabrication, engineers and fabricators can ensure high-quality results and reliable performance in their intended applications.