Drill Pipe and Drill Collar

Drill Pipe and Drill Collar

Introduction

Drill pipes and drill collars are crucial components of the drill string in oil and gas drilling operations. They play significant roles in drilling efficiency, well integrity, and overall operational success.

Drill Pipe

Drill pipes are heavy, seamless tubes that rotate the drill bit and circulate drilling fluid. They are made of high-strength steel and are designed to withstand the rigorous conditions of drilling operations.

Drill Pipe Size:

OD: 60.32mm-168.28mm

WT: 6.45-12.7mm

LENGTH: R1, R2, R3

Heavy Weigh Drill Pipe

OD: 2-3/8″ to 6-5/8″

LENGTH:,Range 2 and 3

Grades: E75, X95, G105, S135

Connection threads:NC26, NC31, NC38, NC40, NC46, NC50, 5 1/2FH.6 5/8FH.

Pipe Standard:API 5DP E75, X95, G105, S135

Upset Style:IU, EU, IEU

Connection:NC26, NC31, NC38, NC40, NC46, NC50, 5 1/2FH.6 5/8FH.

Application: Drill pipe is for exploration and development of oil and gas wells.

Specifications

- Outside Diameter (O.D.): Common sizes range from 2 3/8 inches to 6 5/8 inches.

- Length: Typically 31 feet (9.45 meters) per joint, but can vary.

- Wall Thickness: Varies depending on the grade and size.

- Grade: Includes E-75, X-95, G-105, S-135, each indicating different tensile strengths.

- Connection: Tool joints with threaded connections, such as API Regular, IF, and NC.

Functions

- Rotational Power: Transmits rotational power from the surface to the drill bit.

- Drilling Fluid Circulation: Allows drilling fluid to flow down to the drill bit and back up the annulus, carrying cuttings to the surface.

- Weight Support: Supports the weight of the drill string and the forces encountered during drilling.

Types

- Standard Drill Pipe: Used in most drilling operations.

- Heavy Weight Drill Pipe (HWDP): Thicker and heavier, used to transition between the drill pipe and the drill collar.

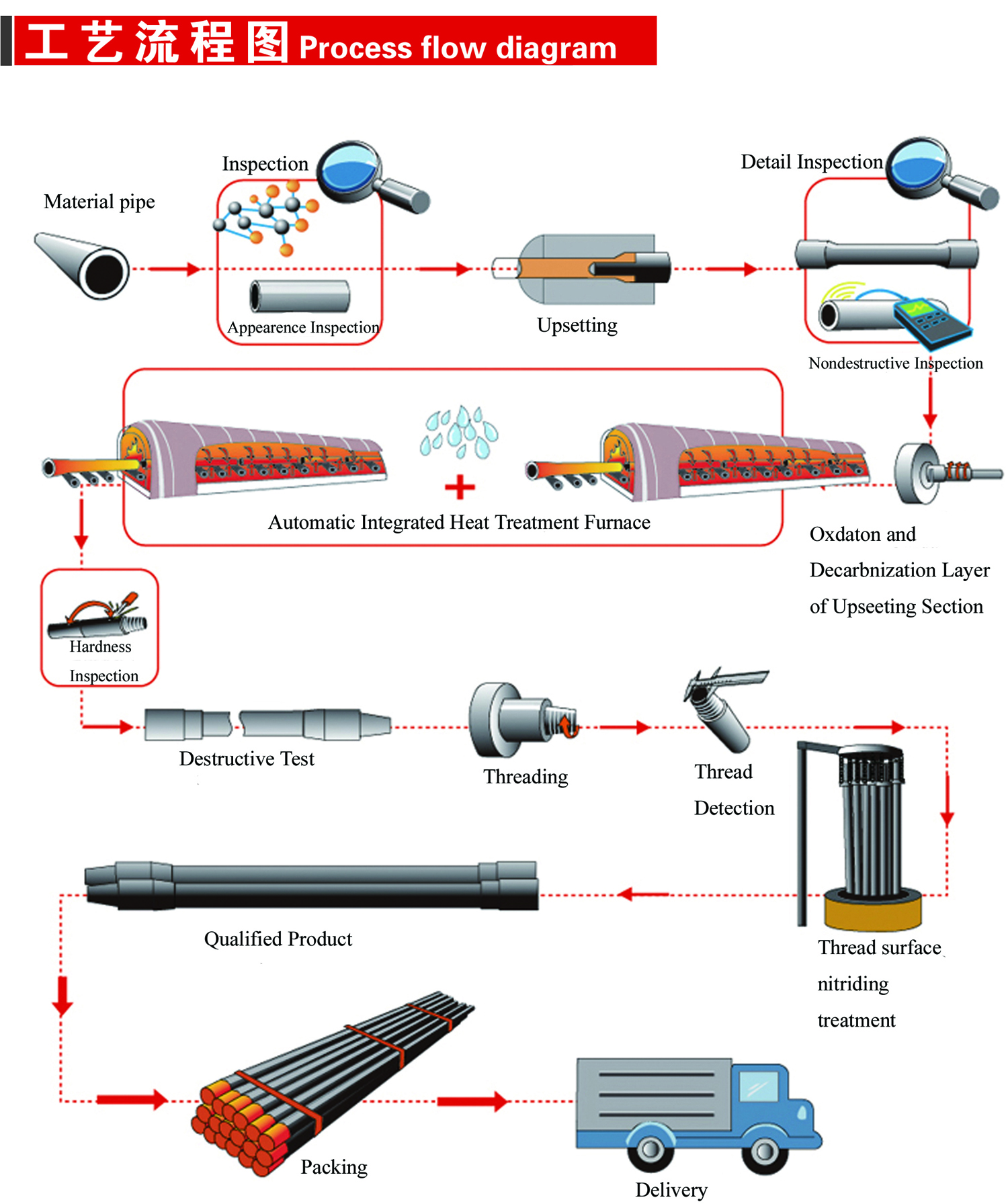

Manufacturing Process

- Seamless Steel Tubing: Produced through the hot rolling process.

- Heat Treatment: Enhances strength and toughness.

- Tool Joint Welding: Tool joints are welded onto the pipe ends.

- Inspection and Testing: Includes non-destructive testing (NDT) for defects, dimensional checks, and pressure testing.

Drill Collar

Drill Collars

– OD: 3 1/8″-11″

– Length: 30Ft / 31Ft / 43Ft / R1~R3

– Standard: API 5DP/API Spec 7-1 E75,X95,G105,S135

– Connection Type: NC, REG, FH, IF

– Thread: NC26, NC31, NC38, NC40, NC46, NC50,5.1 / 2FH

– Material: Stainless Steel / Alloy Steel /Carbon Steel / 4145H

– Classification: Non Magnetic Drill Collar, Slick Drill Collar, Spiral Drill Collar,Square Drill Collars, Monel Drill Collar, Pony Drill Collar, Spesifikasi Drill Collar

Application

– Oil And Gas Well Drilling

– Oilfield Drilling

– Mine Blasting

– Water Well Drilling

– Geothermal Wells Drilling

– Fore Poling

– Coal And Nonferrous Metal Mining Projects

Drill collars are heavy, thick-walled tubular pieces used to apply weight on the drill bit. They are positioned at the bottom of the drill string, just above the bit.

Specifications

- Outside Diameter (O.D.): Common sizes range from 3 1/8 inches to 11 inches.

- Length: Typically 31 feet (9.45 meters) per joint.

- Wall Thickness: Significantly thicker than drill pipes to provide the necessary weight.

- Material: Non-magnetic and standard steel grades.

- Connection: API connections similar to drill pipes.

Functions

- Weight on Bit (WOB): Provides the necessary weight to drill through rock formations.

- Stiffness: Reduces bending and buckling of the drill string.

- Vibration Dampening: Helps absorb and dampen vibrations encountered during drilling.

Types

- Standard Drill Collar: Used in most drilling operations.

- Spiral Drill Collar: Designed with spiraled grooves to reduce differential sticking.

- Non-Magnetic Drill Collar: Used in directional drilling to avoid interference with measurement while drilling (MWD) tools.

Manufacturing Process

- Forging: Drill collars are typically forged from steel billets.

- Heat Treatment: Improves mechanical properties.

- Machining: Precision machining for connections and surface finish.

- Inspection and Testing: Includes magnetic particle inspection, ultrasonic testing, and dimensional verification.

Comparison

| Feature | Drill Pipe | Drill Collar |

|---|---|---|

| Primary Function | Transmit rotational power and circulate drilling fluid | Provide weight on bit (WOB) and stiffness |

| Typical O.D. | 2 3/8″ – 6 5/8″ | 3 1/8″ – 11″ |

| Length | 31 feet (9.45 meters) | 31 feet (9.45 meters) |

| Wall Thickness | Varies | Significantly thicker |

| Material | High-strength steel | Standard and non-magnetic steel |

| Connection | Tool joints with threaded connections | API connections |

Specification

Drill Pipe Specifications:

| outer diameter |

normal weight |

steel grade |

wall thickness |

upset ends |

tool joint designation |

||

| in | mm | in | mm | ||||

| 2 3/8 | 60.32 | 6.65 | E,X,G | 0.280 | 7.11 | EU | NC26 |

| 2 7/8 | 73.02 | 10.40 | E,X,G,S | 0.362 | 9.19 | EU | NC31 |

| 3 1/2 | 88.90 | 9.50 | E | 0.254 | 6.45 | EU | NC38 |

| 13.30 | E,X,G,S | 0.368 | 9.35 | EU | NC38 | ||

| 13.50 | E,X,G | 0.449 | 11.40 | EU | NC38 | ||

| S | 0.449 | 11.40 | EU | NC40 | |||

| 4 | 101.60 | 14.00 | E,X,G,S | 0.330 | 8.38 | IU | NC40 |

| E,X,G,S | 0.330 | 8.38 | EU | NC46 | |||

| 4 1/2 | 114.30 | 13.75 | E | 0.271 | 6.88 | IU | NC46 |

| 13.75 | E | 0.271 | 6.88 | EU | NC46 | ||

| 16.60 | E,X,G,S | 0.337 | 8..56 | EU | NC50 | ||

| 20.00 | E,X,G,S | 0.430 | 10.92 | EU | NC50 | ||

| 16.60 | E,X,G,S | 0.337 | 8.56 | IEU | NC46 | ||

| 20.00 | E,X,G,S | 0.430 | 10.92 | IEU | NC46 | ||

| 5 | 127.00 | 19.50 | E,X,G,S | 0.362 | 9.19 | IEU | NC50 |

| 19.50 | E,X,G,S | 0.362 | 9.19 | IEU | 5 1/2 FH | ||

| 25.60 | E,X,G | 0.500 | 12.70 | IEU | NC50 | ||

| 25.60 | E,X,G,S | 0.500 | 12.70 | IEU | 5 1/2 FH | ||

| 5 1/2 | 139.70 | 21.90 | E,X,G,S | 0.361 | 9.17 | IEU | 5 1/2 FH |

| 24.70 | E,X,G,S | 0.415 | 10.54 | IEU | 5 1/2 FH | ||

| 6 5/8 | 168.28 | 25.20 | E,X,G,S | 0.330 | 8.38 | IEU | 6 5/8 FH |

| 27.70 | E,X,G,S | 0.362 | 9.19 | IEU | 6 5/8 FH | ||

Note: EU— external upset; IU— internal upset; IEU—internal & external upset.

Drill collar Specifications:

|

Drill Collor Number*

|

Outside Diameter,

in. |

Inside Diameter,

in. |

Length,

ft |

Approximate Weight,

lb/ft |

Typical Bending

Strength Ratio |

|

NC 23-31

|

3-1/8

|

1-1/4

|

30

|

22

|

2.57:1

|

|

NC 26-35 (2-3/8 IF)

|

3-1/2

|

1-1/2

|

30

|

27

|

2.42:1

|

|

NC 31-41 (2-7/8 IF)

|

4-1/8

|

2

|

30 or 31

|

34

|

2.43:1

|

|

NC 35-47

|

4-3 /4

|

2

|

30 or 31

|

47

|

2.58:1

|

|

NC 38-50 (3-1/2 IF)

|

5

|

2-1/4

|

30 or 31

|

54

|

2.38:1

|

|

NC 44-60

|

6

|

2-1/4

|

30 or 31

|

83

|

2.49:1

|

|

NC 44-60

|

6

|

2-13 /16

|

30 or 31

|

76

|

2.84:1

|

|

NC 44-62

|

6-1/4

|

2-1/4

|

30 or 31

|

91

|

2.91:1

|

|

NC 46-62 (4 IF)

|

6-1/4

|

2-13 /16

|

30 or 31

|

84

|

2.63:1

|

|

NC 46-65 (4 IF)

|

6-1/2

|

2-1/4

|

30 or 31

|

100

|

2.76:1

|

|

NC 46-65 (4 IF)

|

6-1/2

|

2-13 /16

|

30 or 31

|

93

|

3.05:1

|

|

NC 46-67 (4 IF)

|

6-3 /4

|

2-1/4

|

30 or 31

|

109

|

3.18:1

|

|

NC 50-70 (4-1/2 IF)

|

7

|

2-1/4

|

30 or 31

|

118

|

2.54:1

|

|

NC 50-70 (4-1/2 IF)

|

7

|

2-13 /16

|

30 or 31

|

111

|

2.73:1

|

|

NC 50-72 (4-1/2 IF)

|

7-1/4

|

2-13 /16

|

30 or 31

|

120

|

3.12:1

|

|

NC 56-77

|

7-3 /4

|

2-13 /16

|

30 or 31

|

140

|

2.70:1

|

|

NC 56-80

|

8

|

2-13 /16

|

30 or 31

|

151

|

3.02:1

|

|

6-5/8 API Reg

|

8-1/4

|

2-13 /16

|

30 or 31

|

162

|

2.93:1

|

|

NC 61-90

|

9

|

2-13 /16

|

30 or 31

|

196

|

3.17:1

|

|

7-5/8 API Reg

|

9-1/2

|

3

|

30 or 31

|

217

|

2.81:1

|

|

NC 70-97

|

9-3 /4

|

3

|

30 or 31

|

230

|

2.57:1

|

|

NC 70-100

|

10

|

3

|

30 or 31

|

243

|

2.81:1

|

|

8-5/8 API Reg

|

11

|

3

|

30 or 31

|

300

|

2.84:1

|

| O.D. | cutting depth | Lead ±25.4 | ||

| mm | in | A(mm) | B(mm) | mm |

| 86 | 3.375 | 3.5±0.79 | / | 679 |

| 98.4 | 3.875 | 4.0±0.79 | / | 914 |

| 101.6~111.1 | 4~4 1/8 | 4.8±0.79 | / | 914 |

| 114.3~130.2 | 4 1/2~5 1/8 | 5.6±0.79 | / | 965 |

| 133.4~146.1 | 5 1/4~5 3/4 | 6.4±0.79 | / | 1067 |

| 149.2~161.9 | 5 7/8~6 3/8 | 7.1±1.59 | / | 1067 |

| 165.1~177.8 | 6 1/2~7 | 7.9±1.59 | / | 1168 |

| 181.0~200.0 | 7 1/8~7 7/8 | 8.7±1.59 | 5.6±0.79 | 1626 |

| 203.2~225.4 | 8~8 7/8 | 9.5±1.59 | 6.4±0.79 | 1727 |

| 228.6~250.8 | 9~9 7/8 | 10.3±2.37 | 7.1±1.59 | 1829 |

| 254.0~276.2 | 10~10 7/8 | 11.1±2.37 | 7.9±1.59 | 1930 |

| 279.4 | 11 | 11.9±2.37 | 8.7±1.59 | 2032 |

Standard

Drill Pipe Dimension Tolerances

| Tolerance | ||

|

Drill-pipe-body Outside Diameter |

Pipe body

|

D≤101.60mm,±0.79mm |

| D≥114.30mm,+1.0%, -0.5%D | ||

|

Drill-pipe-body behind the Meu |

D≥60.32~≤88.90mm,+2.38%, -0.79%D | |

| D>88.90~≤127.00mm,+2.78mm, -0.75%D | ||

| D>127.00~≤168.28mm,+3.18mm,-0.75%D | ||

| Wall Thickness | 0, -12.5%t | |

Drill Pipe Chemical Composition, Mass Fraction(%)

|

steel grade |

P (%) | S (%) | |

| ≤ | ≤ | ||

|

Pipe body |

E | 0.030 | 0.020 |

| X, G, S | 0.020 | 0.015 | |

| Tool Joint | 0.020 | 0.015 | |

Drill Pipe Mechanical Properties

|

steel grade |

tensile properties | (21℃±3℃)

Charpy V-notch longitudinal absorbed-energy (21℃±3℃) |

|||||

|

yield strength (Mpa) |

tensile strength (Mpa) |

elongation(%) |

10*10

average(min) |

10*7.5

average(min) |

10*5

average(min) |

||

| min | max | min | |||||

| E | 517 | 724 | 689 | 54(47) | 43(38) | 30(26) | |

| X | 655 | 862 | 724 | ||||

| G | 724 | 931 | 793 | ||||

| S | 931 | 1138 | 1000 | ||||

Remarks: k—constant, equal to 1944 (62500); A—cross-sectional area of tensile specimen, mm2(in2); Udp—specified minimum tensile strength, MPa(Ib/in2).

| Drill collar Mechanical Performance | |||||

| OD | Yield Strength | Tensile Strength σb | Elongation | Reduction of are | Impact |

| Size | σ0.2 | Mpa(psi) | δ4% | % | Ft.1b |

| Mpa(psi) | |||||

| 3 1/8~6 3/4 | ≥758 | ≥827 | ≥18 | 50 | ≥50 |

| -110,000 | -120,000 | ||||

| 7~10 | ≥689 | ≥758 | ≥20 | ||

| -100,000 | -110,000 | ||||

| Sreel Mark | Drill collar Chemical Composition % | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Al | |

| 4145H | 0.42~0.48 | 0.15~0.35 | 0.90~1.20 | ≤0.03 | ≤0.03 | 0.90~1.20 | 0.15~0.25 | ≤0.2 | 0.025~0.045 |

| Other Elements:N≤0.015,Ni≤0.5 | |||||||||

Process

Conclusion

Drill pipes and drill collars are essential components of the drill string, each serving specific and critical functions. Drill pipes transmit rotational power and circulate drilling fluid, while drill collars provide the necessary weight on the bit and maintain the stiffness of the drill string. Understanding their specifications, functions, and types ensures the selection of the right components for efficient and effective drilling operations.