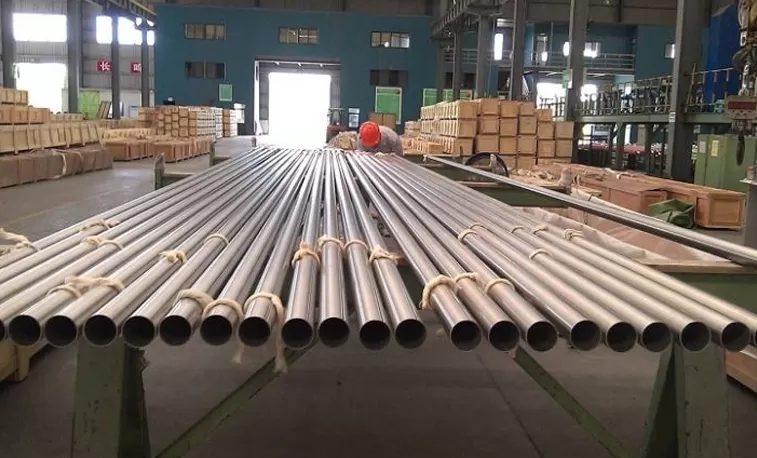

Nickel 200 UNS N02200 WS 2.4060 Alloy steel pipe

First, confirm the corresponding relationship between each grade of Nickel 200. according to UNS N02200 and DIN standard 2.4060 are the number of Nickel 200. For example, It is mentioned that UNS N02200 and 2.4060 correspond to Nickel 200. The table clearly lists the WS 2.4060 corresponding to Alloy 200, indicating that WS may refer to the number in the German material standard, namely Werkstoffnummer, that is, the material number of DIN. Therefore, WS 2.4060 is equivalent to DIN 2.4060, corresponding to UNS N02200, that is, Nickel 200.

Next, in terms of chemical composition, Given different data. It is necessary to compare whether there are any contradictions. For example, The maximum chemical composition values of Nickel 200 in the Nickel 200 include Fe 0.4%, C 0.15%, Mn 0.35%, Si 0.35%, Cu 0.25%, and S 0.01%. and The maximum values in the group are Fe 0.40%, C 0.15%, Mn 0.35%, Si 0.35%, S 0.010%, Cu 0.25%. The maximum Fe in the range is 0.4%, C 0.15%, Mn 0.35%, Si 0.35%, Cu 0.25%, S 0.01%. It looks basically the same. but The table shows that the Nickel 200 has a C content of 0.04%, which may be a mistake or data under different standards. It is necessary to confirm which one is correct. Other information such as It is mentioned that Nickel 200 is 99.6% pure nickel, so the sum of other elements should be lower. Therefore, it is possible The C content in 0.04% may be incorrect, other Both point out that C is 0.15% maximum, so it is more likely to be based on most evidence.

In terms of physical properties, The density is 8.89 g/cm³ and the melting point is 1440℃. The density is mentioned at 0.321 lb/in³, which is converted to about 8.89 g/cm³, which is consistent. It is mentioned that the use temperature is lower than 315℃ and graphitization may occur at high temperatures, so Nickel 201 is required. In terms of application, It is pointed out to be used in chemical equipment, food processing, aerospace, electronic components, etc. For example, The applications mentioned include synthetic fibers, food processing equipment, chemical transport barrels, rocket engines, etc.

Regarding the standards of steel pipes, It is mentioned that ASTM B725 is the standard for welding pipes, and The standards for welded pipes are also mentioned including B725 and B775. The table in the table shows the welding pipe of ASTM B725 corresponding to Nickel 200. In terms of mechanical properties, Tensile strength, yield strength and elongation under different forms are provided, such as the minimum tensile strength of welded pipes in annealed state is 55 ksi, yield strength 15 ksi, and elongation 40%. This data can help users understand the performance of materials.

It should be noted that Nickel 200 is a pure nickel alloy, and the problem is mentioned as “alloy steel pipe”, but according to the evidence, Nickel 200 is pure nickel, which may be mistakenly called by users. However, the welded pipes mentioned in the evidence are nickel alloy pipes, not steel. Therefore, it is necessary to clarify when answering that Nickel 200 is pure nickel material, not alloy steel, but may be processed into steel pipe structural parts.

Based on the information I have searched, users may want to know the relevant parameters, standards, applications, etc. of Nickel 200 steel pipes. Information in each evidence needs to be integrated and attention should be paid to citing the correct source. For example, chemical components Whichever is the basis, reference for application fields , standard reference Mechanical properties reference . At the same time, attention should be paid to differences between the evidence, such as high temperature restrictions and the situation of alternative materials.

Nickel 200 (UNS N02200/WS 2.4060) is a commercial pure nickel alloy (nickel content ≥99.0%), not alloy steel, but it is often processed into structural parts such as pipelines. The following is a detailed analysis:

1. Grade correspondence

- International Standard : UNS number is N02200, DIN standard is W.Nr 2.4060, and the corresponding grade in the ASTM standard is Nickel 200.

- Other names : “WS” in WS 2.4060 may refer to the German Material Standard (Werkstoffnummer), which is consistent with DIN 2.4060.

2. Chemical composition

- Main components : nickel (Ni) ≥99.0%, the upper limit of other elements is iron (Fe) 0.40%, carbon (C) 0.15%, manganese (Mn) 0.35%, silicon (Si) 0.35%, copper (Cu) 0.25%, Sulfur (S) 0.01%.

- Purity characteristics : It is a high-purity nickel alloy, suitable for scenarios with high requirements for material purity, such as food processing and electronic components.

3. Physical and Mechanical Properties

- Density : 8.89 g/cm³, melting point is about 1440℃.

- Mechanical properties (annealing state):

- Tensile strength : ≥55 ksi (379 MPa)

- Yield strength : ≥15 ksi (103 MPa)

- Elongation : ≥40%

- Hardness : HRB 45-70 (cold pull/annealed round rod) .

- Temperature limit : The long-term use temperature must be less than 315°C (600°F), and graphitization may occur at high temperatures. You need to use the low-carbon version of Nickel 201 .

4. Pipeline-related standards and specifications

- Welded pipe standard : ASTM B725, suitable for nickel alloy welded pipes with outer diameter (OD) 3-325mm, wall thickness (WT) 0.5-20mm, and maximum length 25 meters.

- Other forms : Seamless pipes follow ASTM B161/B829, and ASTM B162 is suitable for sheet/strip.

- Surface treatment : Can be provided with pickling (AP), bright annealing (BA) or polished surfaces.

5. Application areas

- Corrosion resistance scenarios : caustic alkali (such as NaOH) processing equipment, chemical transportation containers, food processing equipment .

- Special uses : aerospace components (rocket engine pipelines), electronic components (cathodes, printed circuits) and synthetic fiber production equipment.

- Low-temperature performance : It maintains good toughness in low-temperature environments, suitable for liquefied natural gas (LNG) related equipment .

6. Comparison with other materials

- Difference from Nickel 201 : Nickel 201 (UNS N02201) has a lower carbon content (≤0.02%) and is suitable for high temperature scenarios above 315°C.

- Alternative materials : In sulfur-containing high-temperature alkali liquid, Inconel 600 has better anti-sulfur embrittlement properties .

7. Supply and processing

- Manufacturer example : KANGSHENG can provide ASTM B725 standard welded pipes, with a minimum order volume of 50 kg and a monthly supply capacity of 10 tons.

- Processing technology : including cold rolling/cold pulling (Cold Rolling/Drawing) and solution annealed (Solution Annealed) treatment .