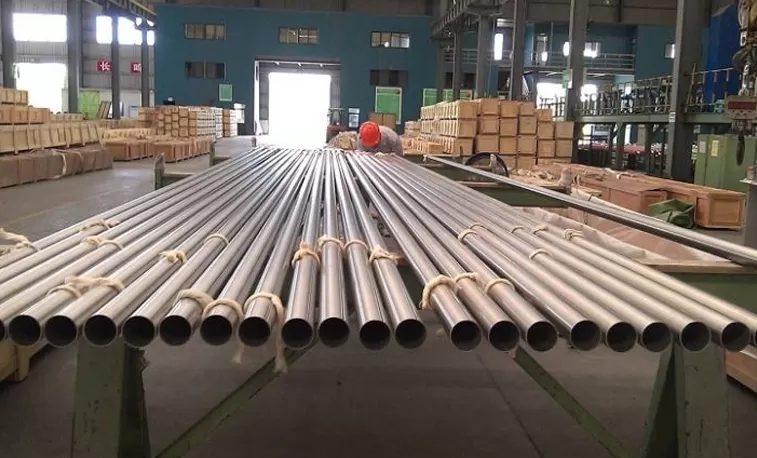

Alloy C276 Nickel Pipe And Tube • UNS N10276 • WNR 2.4819

Alloy C276 Nickel Pipe and Tube • UNS N10276 • WNR 2.4819

Specifications

-

- UNS Number: N10276

- Werkstoff Number (WNR): 2.4819

Chemical Composition

The chemical composition of Alloy C276 typically includes:

- Nickel (Ni): 52.0 min

- Chromium (Cr): 14.5 – 16.5

- Molybdenum (Mo): 15.0 – 17.0

- Iron (Fe): 4.0 – 7.0

- Tungsten (W): 3.0 – 4.5

- Cobalt (Co): 2.5 max

- Manganese (Mn): 1.0 max

- Carbon (C): 0.01 max

- Silicon (Si): 0.08 max

- Phosphorus (P): 0.04 max

- Sulfur (S): 0.03 max

- Vanadium (V): 0.35 max

Mechanical Properties

- Tensile Strength: 690 MPa (100 ksi) min

- Yield Strength (0.2% Offset): 283 MPa (41 ksi) min

- Elongation: 40% min

- Hardness: 100 HRB max

Physical Properties

- Density: 8.89 g/cm³

- Melting Point: 1370 – 1390 °C (2500 – 2530 °F)

- Specific Heat: 427 J/kg-°C (0.102 Btu/lb-°F)

- Thermal Conductivity: 10.2 W/m-°C (70.8 Btu-in/ft²-h-°F)

Applications

Alloy C276 is widely used in various industries due to its exceptional resistance to corrosion and ability to withstand high temperatures and pressures. Common applications include:

- Chemical Processing: Equipment and components for chemical processing, such as reactors, heat exchangers, and piping systems.

- Pollution Control: Systems designed for air pollution control, including scrubbers and stack liners.

- Oil and Gas: Components exposed to sour gas environments and subsea applications.

- Pulp and Paper: Digesters and bleach equipment.

- Marine: Seawater and brine processing equipment.

Corrosion Resistance

Alloy C276 is known for its outstanding resistance to a variety of corrosive media, including:

- Oxidizing and Reducing Environments: Excellent resistance to both oxidizing and reducing acids.

- Pitting and Crevice Corrosion: High resistance to pitting and crevice corrosion in chloride-containing environments.

- Stress-Corrosion Cracking: Superior resistance to stress-corrosion cracking, particularly in chloride-laden environments.

- Sulfuric and Hydrochloric Acid: Excellent performance in sulfuric and hydrochloric acid solutions.

Fabrication and Welding

Alloy C276 is readily fabricated using standard techniques:

- Forming: Good ductility allows for cold and hot forming.

- Machining: Can be machined using standard methods for high-strength superalloys.

- Welding: Can be welded using all common welding techniques, including TIG, MIG, and shielded metal arc welding. Filler metals of matching composition are recommended.

Standards and Specifications

- ASTM: B619, B622, B626 (tubes); B574 (bars and rods); B575 (plates, sheets, and strips)

- ASME: SB619, SB622, SB626 (tubes); SB574 (bars and rods); SB575 (plates, sheets, and strips)

- DIN: 17751

- ISO: 6208

Summary

Alloy C276 is a highly durable and corrosion-resistant material suitable for a wide range of applications in harsh environments. Its versatility, combined with excellent mechanical and physical properties, makes it a preferred choice for critical components in chemical processing, pollution control, oil and gas, marine, and other industries requiring reliable performance under severe conditions.