Anti-Corrosion Coating

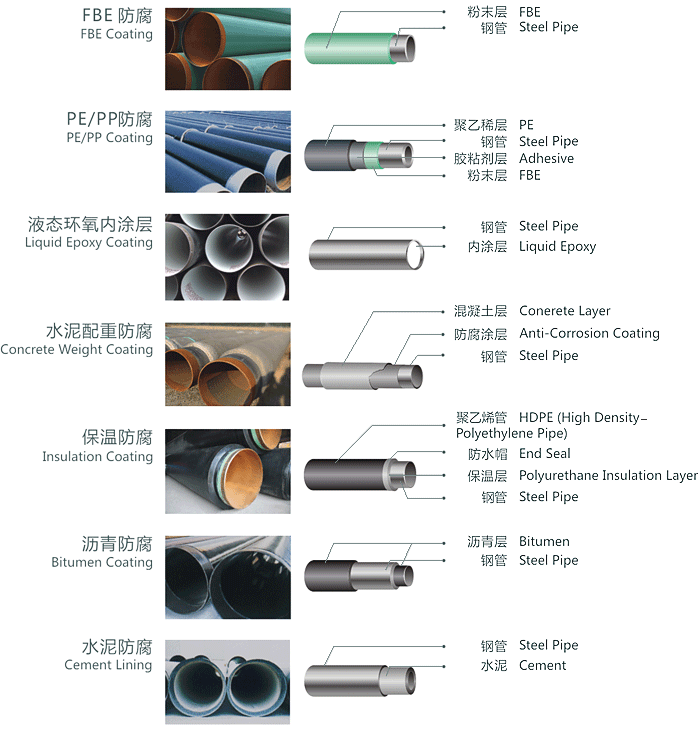

Types of Anti-Corrosion Coatings for Steel Pipelines

Anti-corrosion coatings play a crucial role in protecting steel pipelines from chemical and electrochemical corrosion. These coatings are essential in industries such as petroleum, chemical, natural gas, heat, sewage treatment, water, bridge construction, and more. Let’s explore the various types of anti-corrosion coatings available for steel pipelines:

- IPN8710 Corrosion Protection: IPN8710 is a highly effective coating that provides excellent resistance against a wide range of corrosive substances, including acids, alkalis, salts, oxidizing agents, and water vapor. This coating is chemically inert and prevents corrosion by compensating for water permeability, adhesion, toughness, and fullness. Composed of polyurethane, polyethylene, modified epoxy resin, non-toxic anti-corrosion pigments, and additives, IPN8710 forms a dense coating structure when cured at room temperature. It offers outstanding rust prevention properties and provides excellent protection to the inner walls of pipelines.

- FBE Epoxy Powder Coating: FBE (Fusion Bonded Epoxy) epoxy powder coating forms a film on the surface of the steel pipe. This coating is known for its simplicity of application, easy cleaning process, temperature resistance, impact resistance, and flexibility. It provides a durable barrier against corrosion and enhances the overall performance of the pipeline.

- 2PE/3PE Corrosion Protection: The 2PE/3PE corrosion protection system involves the application of an epoxy powder coating on the steel surface, followed by the winding of a lateral polyethylene coating. This combination of coatings offers exceptional performance and significantly improves the overall corrosion resistance of the pipeline.

- Coal Tar Epoxy Anti-Corrosive Coating: Coal tar epoxy anti-corrosive coating is commonly used for pipe wall corrosion protection. It is made by mixing coal tar pitch, epoxy resin, and anti-corrosion coatings, resulting in a protective layer with a thickness ranging from 0.5mm to 1.0mm. This coating provides excellent resistance against corrosion and helps extend the lifespan of the pipeline.

- High-Density Polyethylene (HDPE) Jacket Corrosion Protection: HDPE jacket corrosion protection involves wrapping the outer surface of the steel pipe with a high-density polyethylene material. This coating offers high mechanical strength and exceptional resistance against corrosion. During transportation, the HDPE material provides reliable protection to the steel pipe, safeguarding it from external factors. To prevent aging, antioxidants, UV stabilizers, and carbon black are added during the manufacturing process. It is important to store these coated pipes in an open-air environment, covering them with tarpaulin and keeping them away from high heat and fire. Additionally, it is crucial to consider temperature conditions during the manufacturing process, as the pipes may be prone to cracking in cold temperatures.

By utilizing these different types of anti-corrosion coatings, ABTERSTEEL ensures the longevity and reliability of its steel pipelines. Each coating is carefully selected based on the specific requirements of the project, providing optimal protection against corrosion and maintaining the integrity of the pipelines for years to come.

External Coating

| Coating Type | Coating Standard |

| Single Layer FBE | SY/T 0315-2005, CAN/CSA Z245.20-2010, |

| DEP 31.40.30.32-Gen-2011, ISO 21809-2-2007, API RP 5L9-2001 | |

| Double Layer FBE | Q/enPC 38-2002, CAN/CSA Z245.20-2010 |

| 2LPE/2LPP Coating | SY/T 0413-2002, GB/T 23257-2009, ISO 21809-1-2009 |

| 3LPE/3LPP Coating | SY/T 0413-2002, GB/T 23257-2009, DIN 30670-1991, CAN/CSA Z245.21-2010, |

| ISO 21809-1-2009, NF A49-711-1992, NF A49-710-1988 | |

| Concrete Weight Coating | Q/HS 3017—2008 |

| Insulation Coating | SY/T 0415-1996, CJ/T 114-2000, EN 253-1994 |

| Bitumen Coating | BS 534-1990 |

Internal Coating

| Coating Type | Coating Standard |

| Internal Liquid Epoxy Coating | API RP 5L2-2002, DEP 31.40.30.35-Gen-2005 |

| Single Layer FBE | API RP 5L7-1988 |

| Internal Cement Lining | BS 534-1990, AWWA C205-2000 |

| Bitumen Coating | BS 534-1990 |