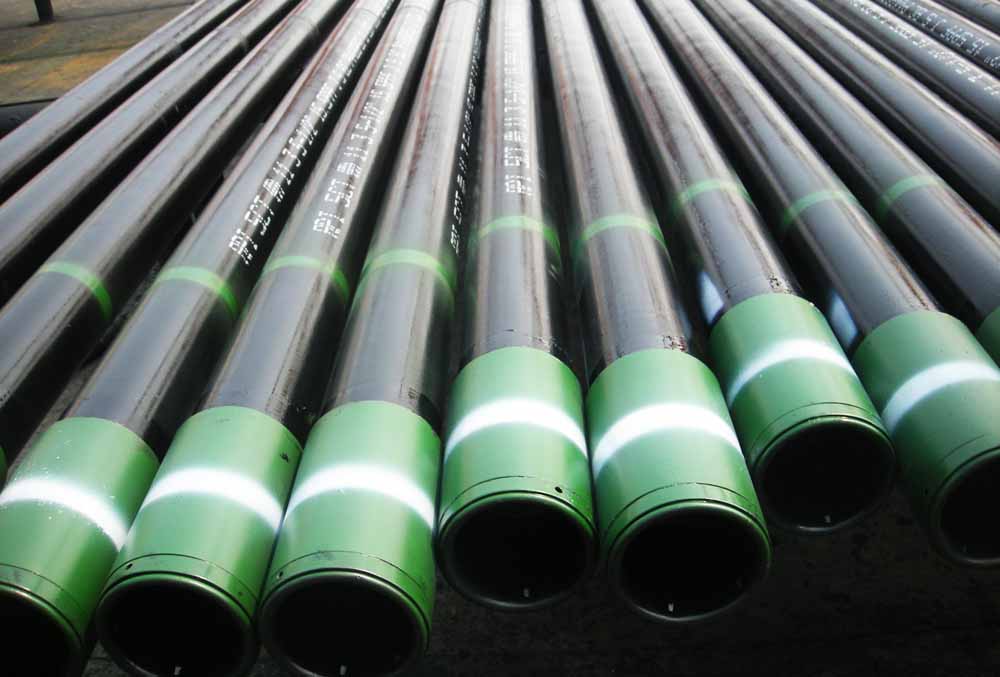

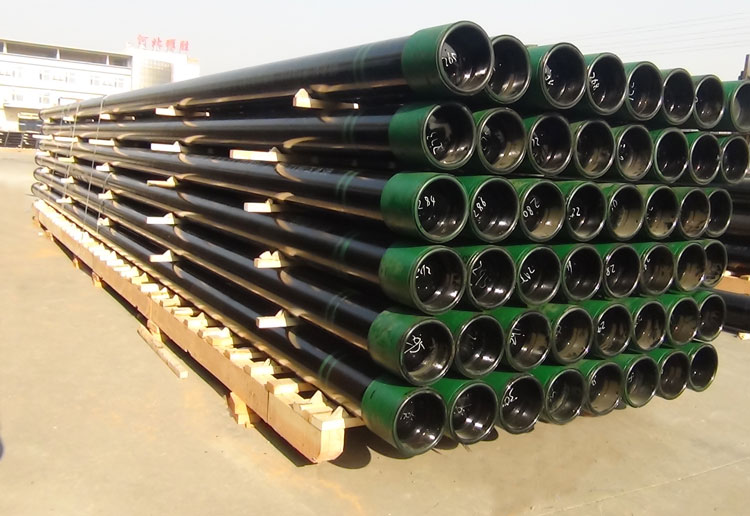

API 5CT C90 Casing Tubing

API 5CT C90 Casing Tubing

Introduction

API 5CT is a specification developed by the American Petroleum Institute (API) for casing and tubing materials used in the oil and gas industry. It covers seamless and welded casing and tubing, and it specifies requirements for various grades. One of the high-strength grades specified under API 5CT is C90, which is commonly used in high-pressure and high-corrosion environments.

Key Features and Grades

API 5CT C90 is designed for use in demanding environments where high strength and corrosion resistance are crucial. C90 casing and tubing are typically used in sour service conditions due to their resistance to hydrogen sulfide (H₂S) and other corrosive elements.

Chemical Composition

The chemical composition of API 5CT C90 is designed to provide excellent mechanical properties and corrosion resistance.

- Carbon (C): 0.30 – 0.37%

- Manganese (Mn): 1.00 – 1.35%

- Phosphorus (P): ≤ 0.020%

- Sulfur (S): ≤ 0.010%

- Silicon (Si): 0.20 – 0.35%

- Nickel (Ni): 0.25 – 0.65%

- Chromium (Cr): 0.80 – 1.10%

- Molybdenum (Mo): 0.20 – 0.30%

Mechanical Properties

API 5CT C90 casing and tubing offer high strength and toughness, making them suitable for challenging environments.

- Tensile Strength: 655 – 760 MPa (95,000 – 110,000 psi)

- Yield Strength: 620 – 850 MPa (90,000 – 125,000 psi)

- Elongation: ≥ 15%

1. Thread type

SC(Short round thread), LC(Long round thread), BC(Buttress thread), Other Premium Thread

2. Length

|

length |

|||

|

Project |

R1 |

R2 |

R3 |

|

Tubing |

6.10-7.32m |

8.53-9.75m |

11.58-12.80m |

|

Casing |

4.88-7.62m |

7.62-10.36m |

10.36-14.63m |

API 5CT Oilfield Casing Pipe

| Size | Linear Mass lb/ft | Outside Diameter | Wall Thickness | Type of end-finish | |||||||||

| inch | mm | inch | mm | Grade | |||||||||

| H-40 | J-55 K-55 | M-65 | L-80 C-95 | N-80 1,Q | C-90 T-95 | P-110 | Q-125 | ||||||

| 4 1/2” | 9.5 | 4.5 | 114.3 | 0.205 | 5.21 | PS | PS | PS | – | – | – | – | – |

| 10.5 | 4.5 | 114.3 | 0.224 | 5.69 | — | PSB | PSB | – | – | – | – | – | |

| 11.6 | 4.5 | 114.3 | 0.25 | 6.35 | — | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 13.5 | 4.5 | 114.3 | 0.29 | 7.37 | — | — | PLB | PLB | PLB | PLB | PLB | – | |

| 15.1 | 4.5 | 114.3 | 0.337 | 8.56 | — | — | – | – | – | – | PLB | PLB | |

| 5” | 11.5 | 5 | 127 | 0.22 | 5.59 | — | PS | PS | – | – | – | – | – |

| 13 | 5 | 127 | 0.253 | 6.43 | — | PSLB | PSLB | – | – | – | – | – | |

| 15 | 5 | 127 | 0.296 | 7.52 | — | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 18 | 5 | 127 | 0.362 | 9.19 | — | — | PLB | PLB | PLB | PLB | PLB | PLB | |

| 21.4 | 5 | 127 | 0.437 | 11.1 | — | — | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.2 | 5 | 127 | 0.478 | 12.14 | — | — | – | PLB | PLB | PLB | PLB | PLB | |

| 24.1 | 5 | 127 | 0.5 | 12.7 | — | — | – | PLB | PLB | PLB | PLB | PLB | |

Manufacturing Process

Seamless and Welded Tubing

API 5CT C90 casing and tubing can be manufactured using either seamless or welded processes, each offering specific advantages depending on the application.

Seamless Process

- Billet Preparation: A solid steel billet is heated and pierced to create a hollow shell.

- Hot Rolling: The hollow shell is rolled to reduce its diameter and wall thickness.

- Cold Drawing (Optional): The tube is cold drawn to achieve precise dimensions and surface finish.

- Heat Treatment: The tube undergoes heat treatment to achieve the required mechanical properties.

- Straightening and Cutting: The tube is straightened and cut to the desired length.

Welded Process

- Strip Preparation: Steel strips are slit to the required width.

- Forming: The strips are formed into a cylindrical shape.

- Welding: The edges of the formed strip are welded together.

- Heat Treatment: The welded tube undergoes heat treatment to achieve the required mechanical properties.

- Sizing and Cutting: The tube is sized and cut to the required length.

Heat Treatment

Heat treatment is crucial to achieve the desired mechanical properties and corrosion resistance. For C90 grade, the typical heat treatments include:

- Quenching and Tempering: Heating the tube to a high temperature, then rapidly cooling (quenching) and reheating to a lower temperature (tempering) to achieve the desired strength and toughness.

Testing Requirements

API 5CT specifies rigorous testing requirements to ensure the quality and performance of C90 casing and tubing:

- Tensile Test: Measures tensile strength, yield strength, and elongation.

- Hardness Test: Ensures the material meets specified hardness levels.

- Impact Test: Assesses the material’s toughness at various temperatures.

- Hydrostatic Test: Ensures the tube can withstand internal pressure without leaking.

- Non-Destructive Testing: Includes ultrasonic, magnetic particle, and radiographic testing to detect any defects.

- Sour Service Testing: Ensures resistance to sulfide stress cracking (SSC) for use in sour environments.

Applications

API 5CT C90 casing and tubing are used in various high-pressure and high-corrosion environments, including:

- Oil and Gas Wells: Casing to protect the wellbore and tubing to transport hydrocarbons.

- Sour Gas Fields: Environments with high H₂S concentrations.

- Offshore Drilling: High-strength casing and tubing for deep-water drilling operations.

- Geothermal Wells: Tubing for high-temperature and high-pressure geothermal applications.

Advantages and Limitations

Advantages

- High Strength: Suitable for high-pressure environments.

- Corrosion Resistance: Excellent resistance to H₂S and other corrosive elements.

- Versatility: Available in both seamless and welded forms.

- Toughness: High toughness ensures durability in challenging conditions.

Limitations

- Cost: Higher cost compared to lower-grade materials due to alloying elements and heat treatment processes.

- Manufacturing Complexity: Requires precise control over chemical composition and heat treatment.

- Availability: Specific grades and sizes may have longer lead times.

Conclusion

API 5CT C90 casing and tubing are essential for high-pressure and high-corrosion applications in the oil and gas industry. Their superior mechanical properties, combined with rigorous manufacturing and testing processes, ensure they meet the demanding requirements of various environments. Understanding the detailed specifications, grades, and applications of API 5CT C90 helps engineers and designers select the right materials for their projects, ensuring safety and efficiency in challenging drilling and production operations.

By examining the chemical composition, mechanical properties, manufacturing processes, and applications, this analysis provides a comprehensive overview of API 5CT C90 casing and tubing, highlighting their significance in high-performance industrial applications.