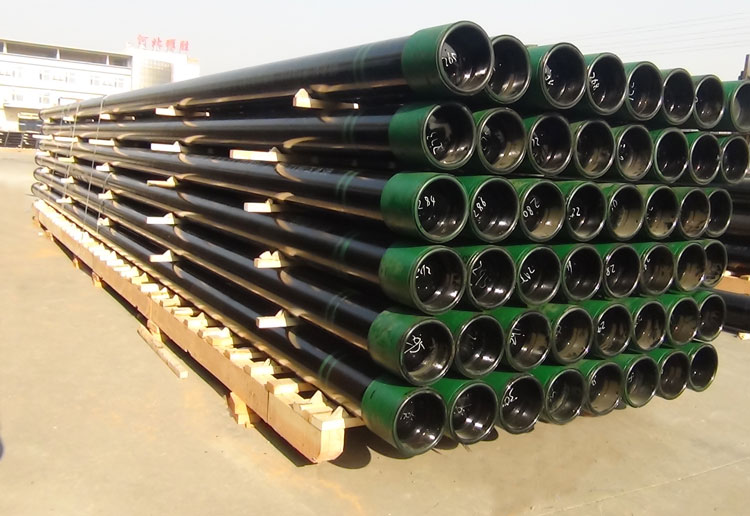

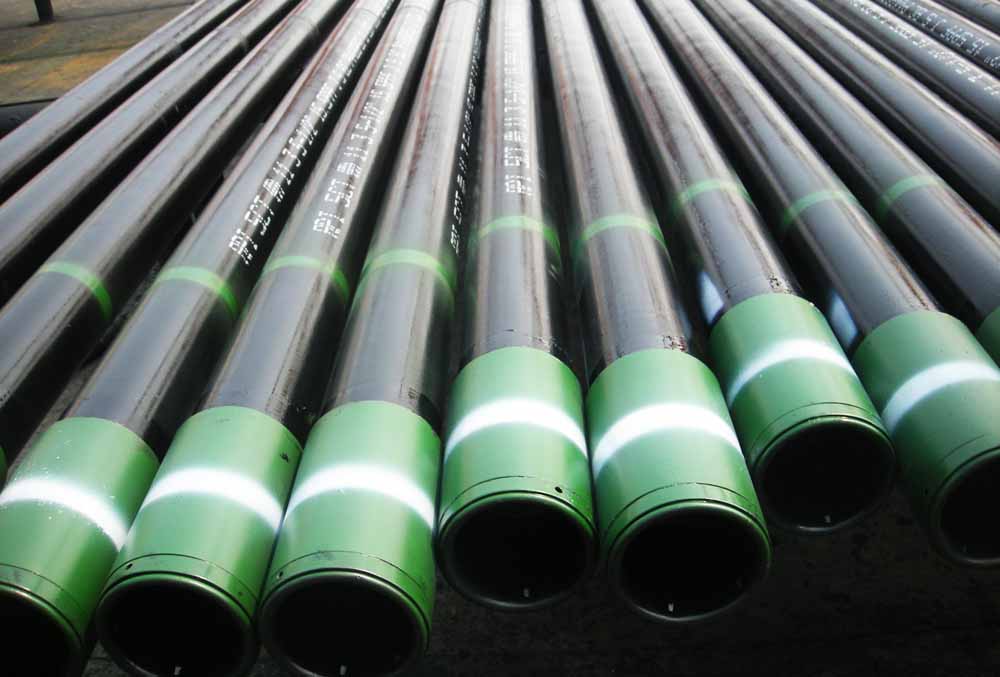

The steel grades of common oilfield API-5CT casing pipe include J55, K55, N80-1, N80Q, and P110. Casing pipe is mostly used for oil well drilling. In accordance with API-5CT and ISO11960 standard, pipes can be classified as STC (short thread), LTC (long thread) and BTC (buttress thread) accompanied with their couplings.

Oilfield casing pipes are positioned into well bore and cemented in place to secure both subsurface formations and the wellbore from collapsing, also to enable drilling mud to circulate and extraction to take place. Casing pipes are normally manufactured using outside dimension sizes from 114.3 mm to 508.0 mm.

The strict quality requirement for steel is due to the harsh working conditions of casing. The steel product should be produced and checked in accordance with special standards or specifications. ISO 11960 and API Spec 5CT have specified the steel product standards of casing.

Types: Seamless Casing ,ERW Casing

|

oilfield api-5ct casing pipe j55 |

API-5CT J55 Casing PipeThe J55 API-5CT casing pipe is a comparatively low steel grade in oil drilling. It is widely applied for shallow oil and gas extraction. Because of its low cost among other grades of steel, it enjoys wider applications, can be generally used in shallow wells, geothermal wells, and water wells. |

|

oilfield api casing pipe k55 |

API-5CT K55 Casing PipeAPI-5CT K55 oilfield casing pipe is very similar to J55, there is no significant difference in the chemical composition and yield strength, however the ultimate tensile strength of K55 is higher than J55 steel, K55/J55 are 655MPa and 517MPa respectively. K55 has a better thermal fatigue resistance property than J55. In present sales, the selling price of theses two types is generally kept the same, their application is very similar. In the oil drilling, K55 API 5CT casing or tubing is a relatively common type. |

|

oilfield api casing pipe n80 |

API-5CT N80 Casing PipeAPI-5CT N80 oilfield casing pipe contains N80-1and N80-Q types. Those two materials are absolutely consistent regarding the chemical composition and mechanical attributes, they are just various in the heat treatment. During heat treatment, N80-1 steel is treated by normalizing and tempering, while N80Q steel is treated by quenching and tempering. As its mechanical properties are higher than J55 and K55 types, it may very well be utilized to certain a little more challenging formations. With deeper downhole depth than J55 and K55 types, it can be applied for the exploitation of middle-level oil and gas. Due to the high capability of N80 material, those API-5CT casing pipes are broadly applied in natural gas as well as coal bed methane extraction, and geothermal wells. |

|

oilfield api casing pipe L80 |

API-5CT L80 Casing PipeL80 belongs to steel grades group of corrosion-resistant casing. L80 API oilfield casing pipe includes L80-1, L80-9Cr, and L80-13Cr. L80-1 is used in the H2S environment, while L80-9Cr and L80-13Cr are used in the CO2 environment. In the corrosive environment in which carbon dioxide predominates, Super 13Cr has a higher corrosion resistance than L80-13Cr. With relatively high price, the product applies to more complicated geological conditions, and runs down deeper into the well. In the exploitation of oil and gas, the use of L80 is less frequent than J55, N80 and other materials. |

|

oilfield api casing pipe p110 |

API-5CT P110 Casing PipeThe P110 API-5CT steel casing pipe is the high grade amongst other grades of steel. White band is marked on the finished casing to point out the materials. During petroleum drilling and producing, this pipe is generally used in a variety of complicated territory due to its higher tensile strength and higher yield. It goes down the deepest into the well among other types. However, the price is comparatively high, as well as the quantity of usage is comparatively few. P110 casing pipe is mainly used in a particular surroundings and when the drilling depth extends to a particular level. |

Connections:

P (Plain end) STC (short threads) LTC (long threads)

BTC (buttress threads) Premium gas-tight connectors

Non-upset ends (NUE) External upset ends (EUE)

Premium gas-tight connectors Others special connectors

Chemical compositions of casing pipe

| Standard | Grade | Chemical compositions(%) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

Mechanical properties of casing pipe

| Grade | Type | Total elongation

under load (%) |

Yield strength

(min)Mpa |

Yield strength

(max)Mpa |

Tensile strength

min Mpa |

Hardness

Max (HRC) |

Hardness

Max (HBW) |

| J55 | – | 0.5 | 379 | 552 | 517 | – | – |

| K55 | – | 0.5 | 379 | 552 | 655 | – | – |

| N80 | 1 | 0.5 | 552 | 758 | 689 | – | – |

| N80 | Q | 0.5 | 552 | 758 | 689 | – | – |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | – | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | – | 0.5 | 655 | 758 | 724 | – | – |

| T95 | – | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | – | 0.6 | 758 | 965 | 862 | – | – |

| Q125 | All | 0.65 | 862 | 1034 | 931 | – | – |