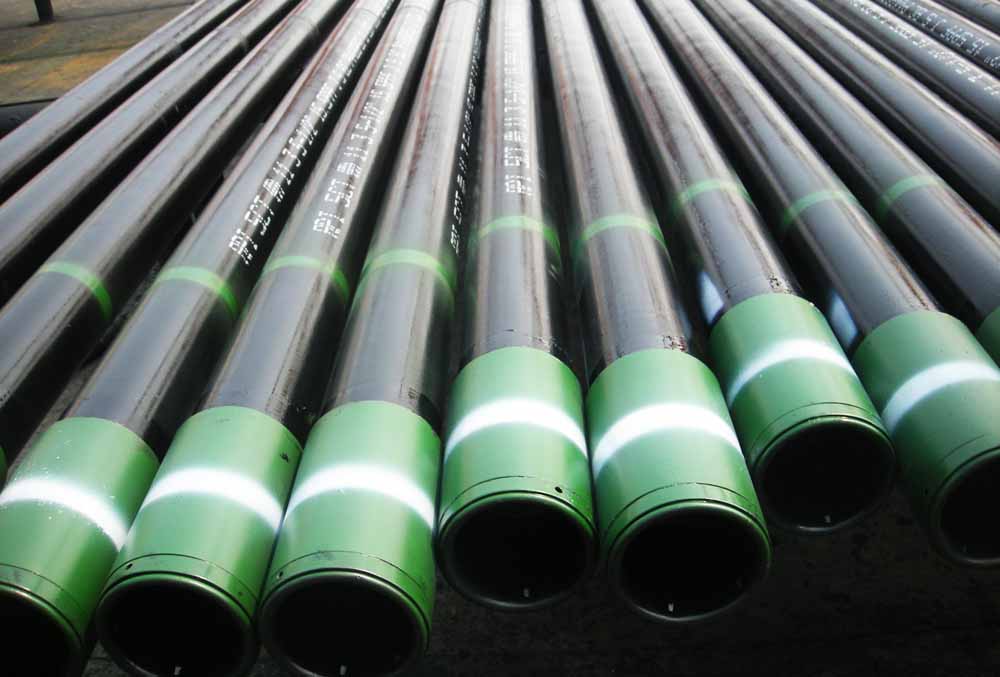

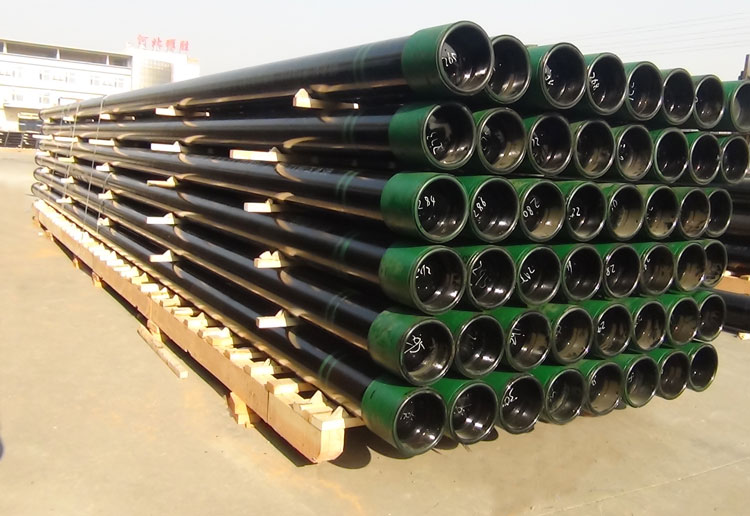

API 5CT L80 Casing Tubing

API 5CT L80 Casing Tubing

Introduction

L80 casing tubing is a high-strength steel pipe used in the oil and gas industry for wellbore casing applications. It is designed to provide structural integrity to the wellbore, prevent contamination of freshwater zones, and ensure a reliable conduit for oil and gas extraction. L80 is a grade within the API 5CT specification. It comes in three types: L80-1, L80 13Cr, and L80 9Cr, each with distinct chemical compositions and mechanical properties for different operational conditions.

API Specifications

Scope

API 5CT specifies the requirements for casing and tubing used in oil and gas wells. L80 casing tubing is designed to meet these standards, ensuring it can withstand the operational pressures and environmental conditions encountered during drilling and production.

Chemical Composition

The chemical composition of L80 casing tubing varies among its three types to provide specific properties:

L80-1

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.43 max |

| Manganese (Mn) | 1.90 max |

| Phosphorus (P) | 0.030 max |

| Sulfur (S) | 0.030 max |

| Silicon (Si) | 0.45 max |

| Chromium (Cr) | 0.25 max |

| Nickel (Ni) | 0.25 max |

| Molybdenum (Mo) | 0.35 max |

| Copper (Cu) | 0.25 max |

L80 13Cr

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.15 max |

| Manganese (Mn) | 1.00 max |

| Phosphorus (P) | 0.020 max |

| Sulfur (S) | 0.010 max |

| Silicon (Si) | 1.00 max |

| Chromium (Cr) | 12.00 – 14.00 |

| Nickel (Ni) | 0.50 max |

| Molybdenum (Mo) | 0.50 max |

L80 9Cr

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.15 max |

| Manganese (Mn) | 1.00 max |

| Phosphorus (P) | 0.020 max |

| Sulfur (S) | 0.010 max |

| Silicon (Si) | 1.00 max |

| Chromium (Cr) | 8.00 – 10.00 |

| Nickel (Ni) | 0.50 max |

| Molybdenum (Mo) | 0.50 max |

Mechanical Properties

The mechanical properties of L80 casing tubing are designed to ensure durability and reliability under various operational conditions. The typical mechanical properties include:

- Tensile Strength: 655-758 MPa (95-110 ksi)

- Yield Strength: Minimum 552 MPa (80 ksi)

- Elongation: Minimum 15% in 2 inches

Pipe Sizes

L80 casing tubing is available in a range of sizes to accommodate different wellbore diameters and depths. Standard sizes are specified by their outside diameter (OD) and wall thickness. Common sizes include:

- Outside Diameter (OD): 4 1/2 inches to 20 inches

- Wall Thickness: Varies based on application requirements (e.g., 0.224 inches, 0.250 inches, etc.)

Technical Details, Dimensions, and Tolerances

Dimensions

The dimensions of L80 casing tubing are specified by their outside diameter (OD) and wall thickness. Standard sizes adhere to API 5CT requirements. Common dimensions include:

- Outside Diameter (OD): 4 1/2 inches to 20 inches

- Wall Thickness: Varies based on application requirements.

Tolerances

API 5CT outlines precise tolerances to ensure the pipes meet quality and performance standards. These tolerances include:

- Outside Diameter (OD): ±1% of the specified OD

- Wall Thickness: ±12.5% of the specified wall thickness

- Weight: ±10% of the nominal weight per unit length

Wall Thickness & Tolerance

The wall thickness of L80 casing tubing is critical for its performance in drilling and production operations. Tolerances on wall thickness ensure consistent performance. The standard tolerances include:

- Wall Thickness Tolerance: ±12.5% of the specified wall thickness.

- Minimum Wall Thickness: The minimum wall thickness must not be less than 87.5% of the specified nominal wall thickness.

Materials and Manufacture

Materials

L80 casing tubing is made from carbon steel and alloy steel, providing a balance of strength, toughness, and corrosion resistance. The material selection varies based on the specific type (L80-1, L80 13Cr, L80 9Cr) to meet different operational requirements.

Manufacture

The manufacturing process for L80 casing tubing involves several steps to ensure quality and performance:

- Steelmaking: High-quality steel is produced through processes such as electric arc furnace (EAF) or basic oxygen furnace (BOF).

- Forming: The steel is formed into cylindrical shapes using processes such as seamless rolling or welding.

- Heat Treatment: The pipes undergo heat treatment processes such as normalizing or quenching and tempering to enhance their mechanical properties.

- Finishing: The pipes are finished to achieve the desired surface quality, dimensions, and tolerances.

Tests

To ensure the quality and performance of L80 casing tubing, several tests are conducted as per API 5CT requirements:

Hydrostatic Test

A hydrostatic test is performed to verify the pipes’ ability to withstand internal pressure. The pipes are filled with water and pressurized to a specified level to check for leaks and structural integrity.

Nondestructive Testing (NDT)

Nondestructive testing methods are used to detect internal and surface defects without damaging the pipes. Common NDT methods include:

- Ultrasonic Testing: High-frequency sound waves are used to detect internal flaws.

- Magnetic Particle Inspection: Detects surface and near-surface defects using magnetic fields.

Mechanical Tests

Mechanical tests are conducted to verify the pipes’ mechanical properties, including:

- Tensile Test: Measures tensile strength, yield strength, and elongation.

- Hardness Test: Verifies hardness levels to ensure compliance with specified limits.

- Flattening Test: Checks the pipe’s ability to withstand deformation without cracking.

Heat Treatment

Heat treatment processes such as normalizing or quenching and tempering may be applied to L80 casing tubing to enhance their mechanical properties and ensure consistent performance:

Normalizing

Normalizing involves heating the pipes to a temperature above the critical temperature and then cooling them in air. This process refines the grain structure, improving toughness and strength.

Quenching and Tempering

Quenching and tempering involves heating the pipes to a high temperature, quenching them in water or oil to rapidly cool, and then reheating to a lower temperature to relieve stresses and improve toughness.