أنابيب الصلب HFI | الأنابيب الحثية عالية التردد

High-Frequency Induction (HFI) steel pipes are a type of Electric Resistance Welded (فدان) pipe that are produced using high-frequency induction welding. This method is known for its efficiency and effectiveness in creating strong, high-quality welds. Here’s an overview of HFI steel pipes, including their manufacturing process, characteristics, والتطبيقات:

HFI (High-Frequency Induction) أنابيب الصلب

عملية التصنيع

- High-Frequency Induction Welding:

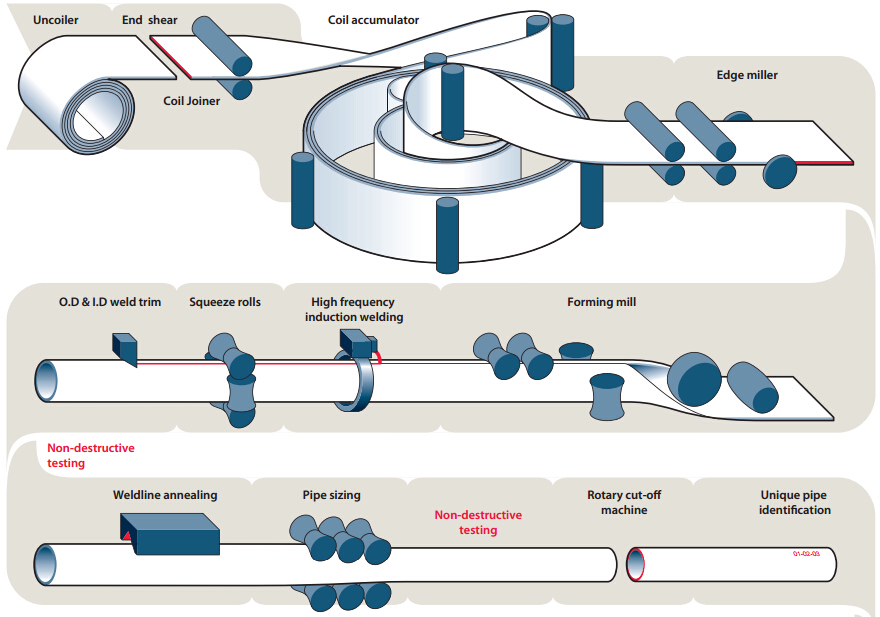

- Induction Coil: The process starts by forming the steel strip into a cylindrical shape using a series of forming rolls.

- Induction Heating: The edges of the steel strip are then heated using an induction coil. This coil generates an alternating magnetic field that induces currents (eddy currents) in the steel.

- لحام: The edges are heated to a temperature sufficient for welding without melting the entire material. The heated edges are then pressed together to form a weld under pressure.

- Cooling and Sizing: بعد اللحام, the pipe is quickly cooled and passed through sizing rolls to ensure the precise dimensions and roundness of the pipe.

صفات

- اللحامات عالية الجودة: HFI welding produces strong, reliable welds with good mechanical properties and minimal defects.

- كفاءة: The process is highly efficient and suitable for mass production, providing high throughput.

- Consistent Dimensions: The precise control during manufacturing results in pipes with consistent dimensions and wall thickness.

- الانتهاء من السطح: عادة, HFI pipes have a smooth surface finish, which is beneficial for many applications.

التطبيقات

- صناعة النفط والغاز: Used for transporting oil, غاز, and other fluids under moderate pressure and temperature conditions.

- Construction and Infrastructure: Utilized in structural applications, such as columns and beams, due to their strength and reliability.

- صناعة السيارات: Used in the manufacturing of various automotive components.

- Water and Sewage Systems: Suitable for water supply lines and sewage systems due to their durability and corrosion resistance.

- الهندسة الميكانيكية والعامة: Employed in various mechanical applications requiring pipes with precise dimensions and good mechanical properties.

Advantages of HFI Steel Pipes

- القوة والمتانة: HFI pipes offer excellent mechanical properties, making them suitable for demanding applications.

- فعالة من حيث التكلفة: The high efficiency of the HFI welding process makes these pipes relatively cost-effective compared to some other types of welded pipes.

- مراقبة الجودة: The process allows for rigorous quality control, ensuring high-quality welds and consistent pipe characteristics.

- براعة: HFI pipes can be produced in a wide range of sizes and thicknesses, making them versatile for various applications.

Comparison with Other Types of Welded Pipes

| ميزة | HFI (High-Frequency Induction) | فدان (المقاومة الكهربائية ملحومة) | EFW (الانصهار الكهربائي الملحومة) |

|---|---|---|---|

| Welding Process | High-frequency induction heating and pressure | Electric resistance heating and pressure | Electric arc or high-frequency induction welding |

| مصدر المادة | لفائف الصلب | لفائف الصلب | ألواح الصلب أو لفائف |

| قوة | High strength, suitable for moderate pressure applications | قوة معتدلة, مناسبة للضغط المنخفض إلى المتوسط | قوة أعلى, مناسبة لتطبيقات الضغط العالي |

| يكلف | Cost-effective due to efficient process | Generally cost-effective | More expensive due to complex process |

| التطبيقات | زيت & خطوط أنابيب الغاز, بناء, السيارات, water systems | خطوط إمداد المياه, مكونات السيارات, تطبيقات الضغط المنخفض إلى المتوسط | زيت & خطوط أنابيب الغاز, التطبيقات الهيكلية, بيئات ذات درجة حرارة عالية |

| سمك الجدار | Consistent wall thickness, can be produced in various sizes | Consistent, typically thinner walls | يمكن إنتاجها بجدران أكثر سمكًا |

| الانتهاء من السطح | Smooth surface finish | Generally smooth finish | قد يكون لها تشطيب أكثر خشونة بسبب عملية اللحام |

- Material Preparation:

- Slitting Line: The process begins with cutting a steel strip of the required size on a slitting line.

- التشكيل البارد: The strip is then fed through a tube mill where it undergoes cold forming using a set of cage rolls and fin passes to form an open pipe.

- High-Frequency Induction Welding:

- Induction Coil: The open pipe passes through a high-frequency inductor, a metal coil with single or multiple windings.

- Induced Current: High-frequency ring current is induced into the pipe, which concentrates at the strip edges converging at the welding point.

- Resistance Heating: The required welding temperature is generated by resistance heating along a narrow zone at the strip edges.

- Pressure Rollers: The heated edges are squeezed together by pressure rollers, resulting in a homogeneous longitudinal weld without any filler metals.

- Flash Removal:

- Inside and Outside Beads: The flash generated on the inside and outside surfaces during welding is removed to the level of the pipe surface using special tools to ensure unobstructed fluid or gas flow.

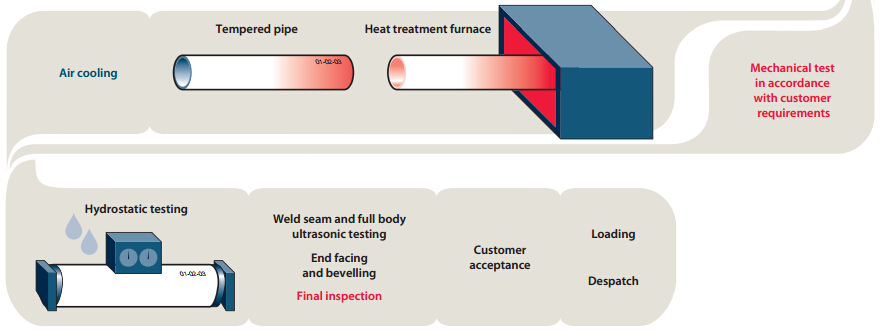

- Post-Weld Treatment:

- Inductive Annealing: The HFI weld undergoes multi-step inductive annealing to ensure the weld area properties match those of the base material.

- التحجيم والقطع: The continuous pipe string is straightened, size rolled, and cut to length by a flying saw.

- Finishing and Testing:

- Further Processing: Pipes are transferred to finishing sections for processes such as straightening, end chamfering/facing, hydro-testing, اختبار غير مدمر, threading, and galvanizing, based on customer requirements.

Expertise and Applications

TWI Expertise:

- Mechanical Properties and Metallurgical Studies: TWI conducts mechanical properties analysis and metallurgical studies on welds.

- Defect Examination: It examines defects and optimizes HF butt welding of tailored blanks.

- Resource Provision: TWI provides testing facilities for fracture mechanics studies, corrosion and metallurgical test equipment, اختبار غير مدمر, process advice, troubleshooting, and tailored training courses.

Application Areas:

- Industries: HFW welded steel pipes are widely used in oil, الغاز الطبيعي, ماء, and other liquid transportation and distribution lines, التدفئة, cooling, and ventilation piping, and steel structures for construction and other general purposes.

- فوائد: These pipes are preferred for their precise production tolerances and high-capacity manufacturing methods.

المواصفات والمعايير

HFI welded steel pipes are produced in compliance with various international standards, including API, ASTM/ASME, من, بكالوريوس, في, و JIS. Below are the specifications and dimensions for different standards:

API المواصفات 5CT

| اسم المنتج | المعيار التنفيذي | البعد (مم) | Steel Code / درجة الصلب |

|---|---|---|---|

| صب | API 5CT | Ø48.3 |

J55, K55, N80, L80 |

| الأنابيب | API 5CT | Ø48.3 |

J55, K55, N80, L80, ح40 |

API SPEC 5L

| اسم المنتج | المعيار التنفيذي | البعد (مم) | Steel Code / درجة الصلب |

|---|---|---|---|

| Line Pipes | API 5L | Ø60.3 |

A25, أ, ب, X42, X46, X52, X56, X60, X65, X70, X80 |