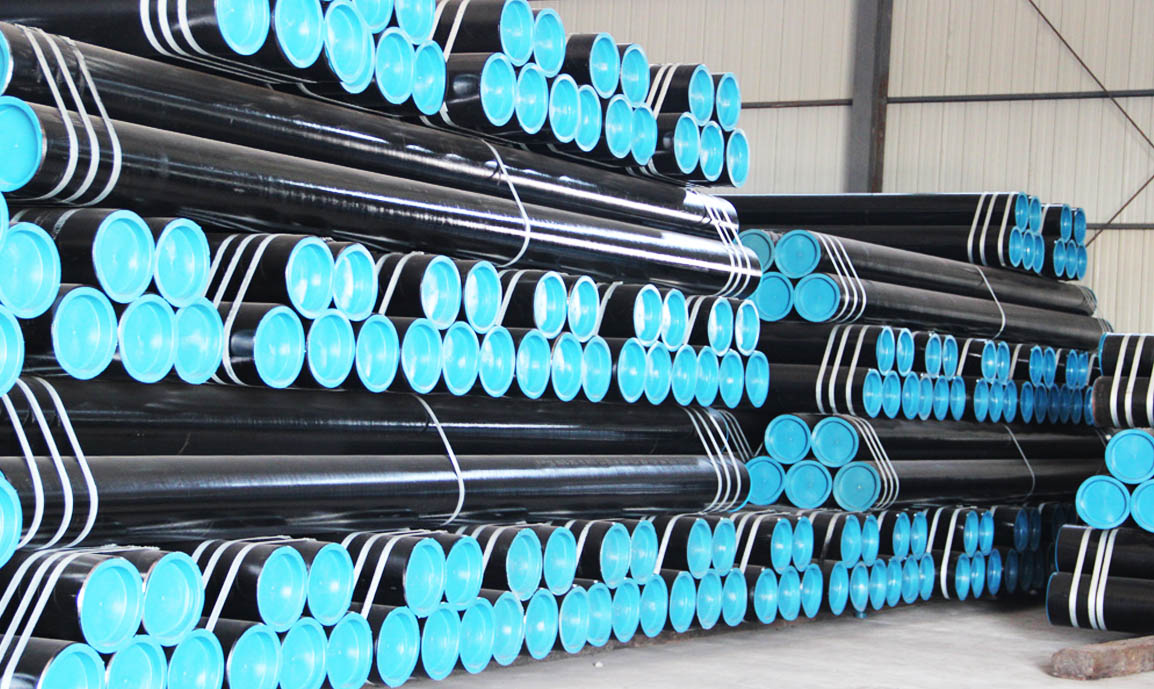

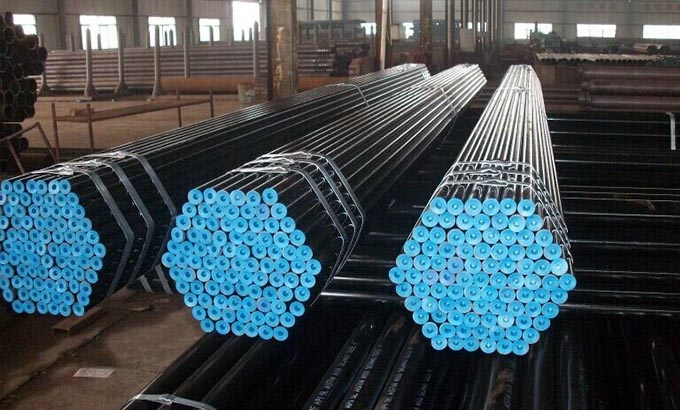

ASTM A192 Seamless Boiler Pipes

ASTM A192 Seamless Boiler Pipe

ASTM A192 is the standard specification for seamless carbon steel boiler tubes for high-pressure service. These tubes are primarily used in the construction of boilers, superheaters, and heat exchangers. Below are the detailed chemical composition, mechanical properties, and specifications for ASTM A192 seamless boiler pipes.

Chemical Composition

The chemical composition of ASTM A192 seamless boiler pipes ensures high strength and durability, suitable for high-pressure environments.

Chemical Composition (%):

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.06-0.18 |

| Manganese (Mn) | 0.27-0.63 |

| Phosphorus (P) | 0.035 max |

| Sulfur (S) | 0.035 max |

| Silicon (Si) | 0.25 max |

Mechanical Properties

The mechanical properties of ASTM A192 seamless boiler pipes ensure they can handle the high pressures and temperatures encountered in boiler systems.

Mechanical Properties:

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 325 (47,000 psi) |

| Yield Strength, min (MPa) | 180 (26,000 psi) |

| Elongation, min (%) | 35% on 2 in. (50 mm) |

Specifications

Specifications for ASTM A192 Seamless Boiler Pipes:

- Standard: ASTM A192 / ASME SA192

- Type: Seamless

- Application: High-pressure boiler tubes

- Manufacturing Process: Hot finished or cold drawn

- Size Range:

- Outside Diameter (OD): 1/2″ to 7″ (12.7mm to 177.8mm)

- Wall Thickness (WT): 0.085″ to 1.000″ (2.2mm to 25.4mm)

- Length: Fixed length or random length, typically up to 12 meters (40 feet)

Applications

ASTM A192 seamless boiler pipes are extensively used in:

- Boilers:

- High-pressure steam boilers

- Water tube boilers

- Superheaters:

- Tubes exposed to high temperatures and pressures

- Heat Exchangers:

- Transfer of heat between fluids

- Power Plants:

- Construction of thermal power plant components

Manufacturing Process

The manufacturing process of ASTM A192 seamless boiler pipes involves:

- Hot Finished or Cold Drawn: Ensures the desired size, shape, and mechanical properties.

- Heat Treatment: Tubes are normalized or stress relieved to achieve the required mechanical properties.

- Inspection and Testing:

- Hydrostatic Test: Ensures the tube can withstand the required pressure without leaking.

- Non-Destructive Testing (NDT): Includes ultrasonic testing, eddy current testing, and radiographic testing to detect any internal or surface defects.

- Dimensional Inspection: Ensures the tubes meet the specified dimensions and tolerances.

- Mechanical Testing: Includes tensile tests, hardness tests, and flattening tests to ensure the tubes meet the required mechanical properties.

Summary

ASTM A192 Seamless Boiler Pipes are essential components in high-pressure boiler systems, known for their high strength, durability, and resistance to high temperatures and pressures. Their seamless construction and stringent manufacturing processes make them ideal for critical applications in boilers, superheaters, and heat exchangers in power plants and other industrial settings.

Advantages of Using ASTM A192 Seamless Boiler Pipes in Power Plants

ASTM A192 seamless boiler pipes are widely used in power plants due to their numerous advantageous properties that make them suitable for high-pressure and high-temperature environments. Here are the key advantages:

1. High-Pressure Resistance

ASTM A192 pipes are designed to withstand high pressure, which is essential for boiler systems in power plants. Their seamless construction ensures uniform strength and eliminates the weak points that can occur in welded pipes.

- Benefits: Increased safety and reliability in high-pressure applications.

2. High-Temperature Performance

These pipes are manufactured to handle the extreme temperatures encountered in boiler systems. The specific chemical composition and heat treatment processes ensure that the pipes maintain their mechanical properties at high temperatures.

- Benefits: Longer service life and consistent performance under thermal stress.

3. Seamless Construction

The seamless nature of ASTM A192 pipes means there are no welded joints, which are potential points of failure. This construction method provides higher overall strength and durability.

- Benefits: Enhanced structural integrity and reduced risk of leaks or failures.

4. Corrosion Resistance

While ASTM A192 pipes are primarily carbon steel, the controlled composition and manufacturing processes provide a degree of resistance to corrosion, particularly in high-temperature environments.

- Benefits: Reduced maintenance costs and longer operational life in corrosive environments.

5. Uniform Wall Thickness

The manufacturing process ensures that the pipes have a uniform wall thickness, which is critical for maintaining consistent pressure and temperature resistance throughout the length of the pipe.

- Benefits: Improved efficiency and performance of the boiler system.

6. Mechanical Properties

The pipes have excellent mechanical properties, including high tensile strength and yield strength, which are crucial for the demanding conditions in power plant boilers.

- Benefits: Enhanced ability to withstand mechanical stress without deformation.

7. Versatility in Application

ASTM A192 pipes can be used in various components of power plants, including:

- Boilers: For high-pressure steam generation.

- Superheaters: For increasing the temperature of steam beyond its saturation point.

- Heat Exchangers: For efficient heat transfer between fluids.

- Benefits: Versatile application across different parts of the power plant, enhancing overall efficiency.

8. Quality Assurance

ASTM A192 pipes undergo rigorous testing and inspection, including hydrostatic testing, non-destructive testing (NDT), and mechanical testing, to ensure they meet stringent quality standards.

- Benefits: High reliability and assurance of performance, reducing the risk of unexpected failures.

9. Compliance with Standards

Compliance with ASTM A192 standards ensures that the pipes meet internationally recognized benchmarks for quality and performance.

- Benefits: Easy integration into projects and guaranteed compatibility with other components.

10. Ease of Installation

The dimensions and properties of ASTM A192 pipes are standardized, making them easier to handle, fit, and install in complex boiler systems.

- Benefits: Reduced installation time and costs, with improved precision and fit.