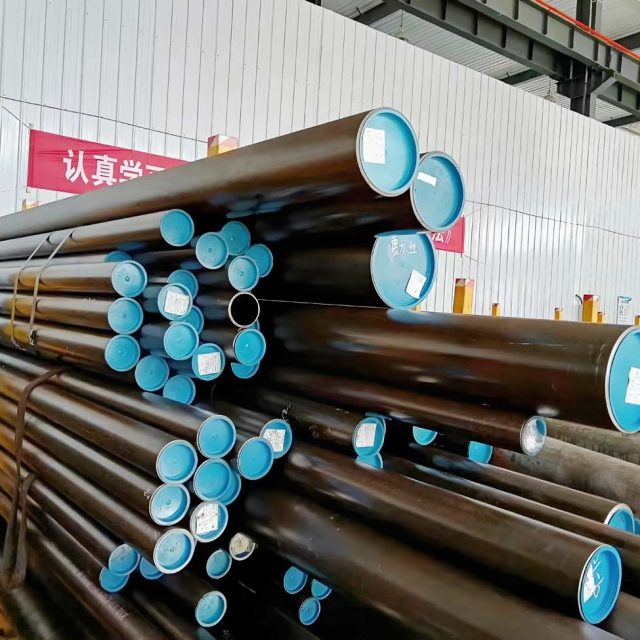

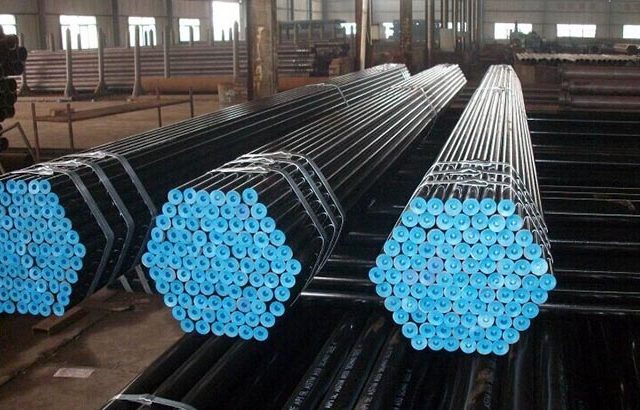

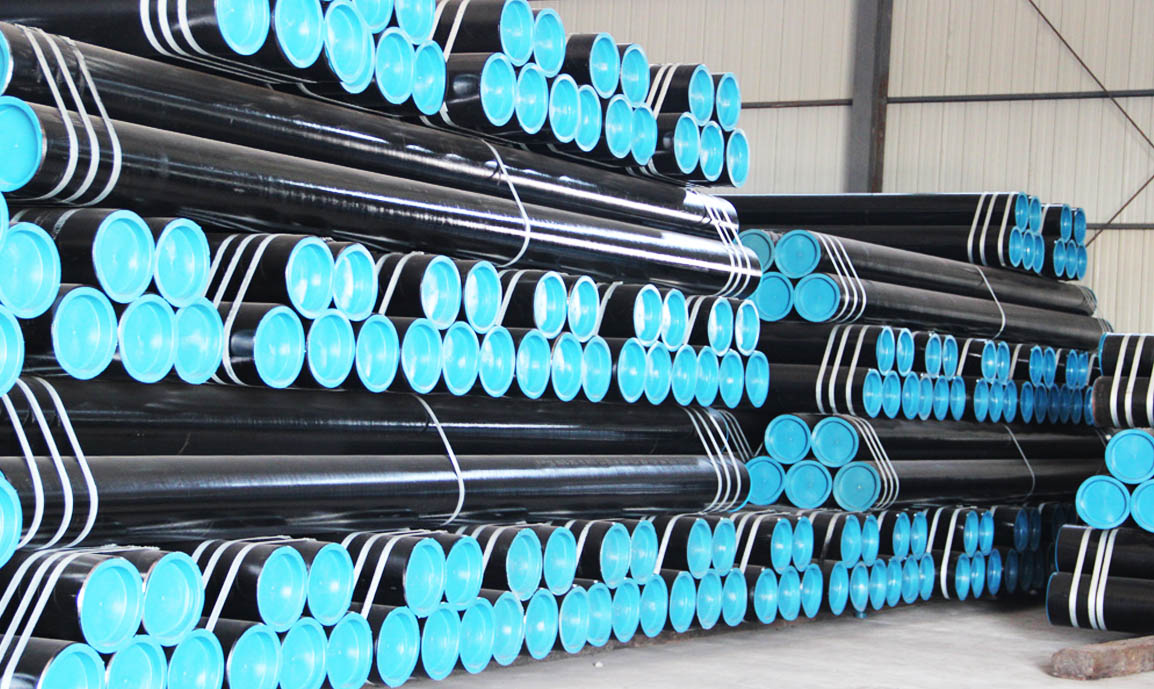

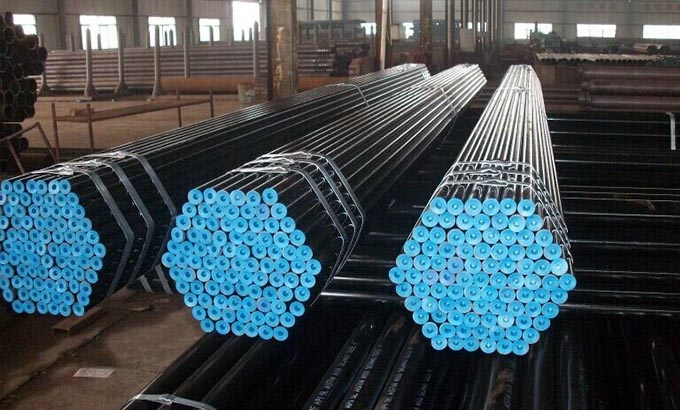

ASTM A53 Seamless Steel Pipe

ASTM A53: Seamless Steel Pipe Specifications

ASTM A53 is a standard specification for seamless and welded black and hot-dipped galvanized steel pipe. These pipes are intended for mechanical and pressure applications and are also acceptable for ordinary uses in steam, water, gas, and air lines.

Scope

ASTM A53 covers seamless and welded black and hot-dipped galvanized steel pipe in NPS 1/8 to NPS 26 (DN 6 to DN 650) inclusive, with nominal wall thickness as given in ASME B36.10M. The standard includes both Type E (electric-resistance welded), Type F (furnace-welded), and Type S (seamless) pipes.

abtersteel Co., Ltd has a full range of stock in ASTM A53 steel pipe (ASME SA53 steel pipe), specifically in Grade B, ranging from NPS ¼” to NPS 26” O.D., with wall thicknesses from Schedules 10 through 160, STD, XH, and XXH. Commonly requested unscheduled walls up to 4” and certified minimum wall items are also available.

Key Features

ASTM A53 Steel Pipe Specifications

ASTM A53 pipe comes in three types and two grades:

- Types:

- Type F: Furnace butt-welded or may have a continuous weld (Grade A only).

- Type E: Electric resistance-welded (Grades A and B).

- Type S: Seamless (Grades A and B).

- Grades:

- Grade A: Lower tensile strength.

- Grade B: Higher tensile strength.

Note: A53 Grade B Seamless pipe is commonly dual certified to ASTM A106 Grade B.

Application: Pipe ordered under this specification is intended for mechanical and pressure applications and is suitable for welding, forming operations involving coiling, bending, and flanging. Specific qualifications include:

- Type F is not intended for flanging.

- Types S and E are preferred for close coiling or cold bending, with Grade A as the preferred grade, though Grade B can also be used.

- Type E can be furnished either non-expanded or cold expanded at the option of the manufacturer.

Chemical Composition

The chemical composition requirements for ASTM A53 pipes vary by grade and type.

Chemical Composition (%):

| Element | Grade A (max) | Grade B (max) | Grade C (max) |

|---|---|---|---|

| Carbon (C) | 0.25 | 0.30 | 0.35 |

| Manganese (Mn) | 0.95 | 1.20 | 1.35 |

| Phosphorus (P) | 0.05 | 0.05 | 0.05 |

| Sulfur (S) | 0.045 | 0.045 | 0.045 |

| Copper (Cu) | 0.40 | 0.40 | 0.40 |

| Nickel (Ni) | 0.40 | 0.40 | 0.40 |

| Chromium (Cr) | 0.40 | 0.40 | 0.40 |

| Molybdenum (Mo) | 0.15 | 0.15 | 0.15 |

| Vanadium (V) | 0.08 | 0.08 | 0.08 |

Mechanical Properties

The mechanical properties specified in ASTM A53 ensure the pipes can withstand the required service conditions.

Mechanical Properties:

| Property | Grade A | Grade B | Grade C |

|---|---|---|---|

| Tensile Strength, min (MPa) | 330 | 415 | 485 |

| Yield Strength, min (MPa) | 205 | 240 | 275 |

| Elongation, min (%) | 25 | 22 | 20 |

Manufacturing Process

- Seamless Pipe (Type S): Manufactured by hot working and, if necessary, by cold finishing.

- Welded Pipe (Type E and Type F): Manufactured by electric-resistance welding (Type E) or furnace welding (Type F).

Heat Treatment

- Pipes may undergo heat treatment processes like annealing, normalizing, quenching, and tempering to achieve the desired mechanical properties.

Coating and Marking

- Coating: Pipes can be supplied black or hot-dipped galvanized.

- Marking: Each pipe must be marked with the manufacturer’s name or brand, specification number, and grade. Additional markings may include heat number and other information as specified by the purchaser.

Testing

ASTM A53 specifies various tests to ensure the quality and performance of the pipes:

- Hydrostatic Testing: Ensures the pipe can withstand internal pressure without leaking.

- Nondestructive Testing (NDT): Includes ultrasonic testing, radiographic testing, and magnetic particle inspection to detect internal and surface defects.

- Mechanical Testing: Tensile tests, bending tests, flattening tests, and hardness tests.

Dimensional Tolerances

Outside Diameter and Wall Thickness Tolerances:

- Outside Diameter Tolerances: ±1% of the specified outside diameter for sizes up to and including NPS 1½, and ±1.5% for sizes larger than NPS 1½.

- Wall Thickness Tolerances: The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified.

ASTM A53 seamless steel pipes are a versatile and widely used option in various industrial applications, ensuring reliability and performance under diverse conditions.