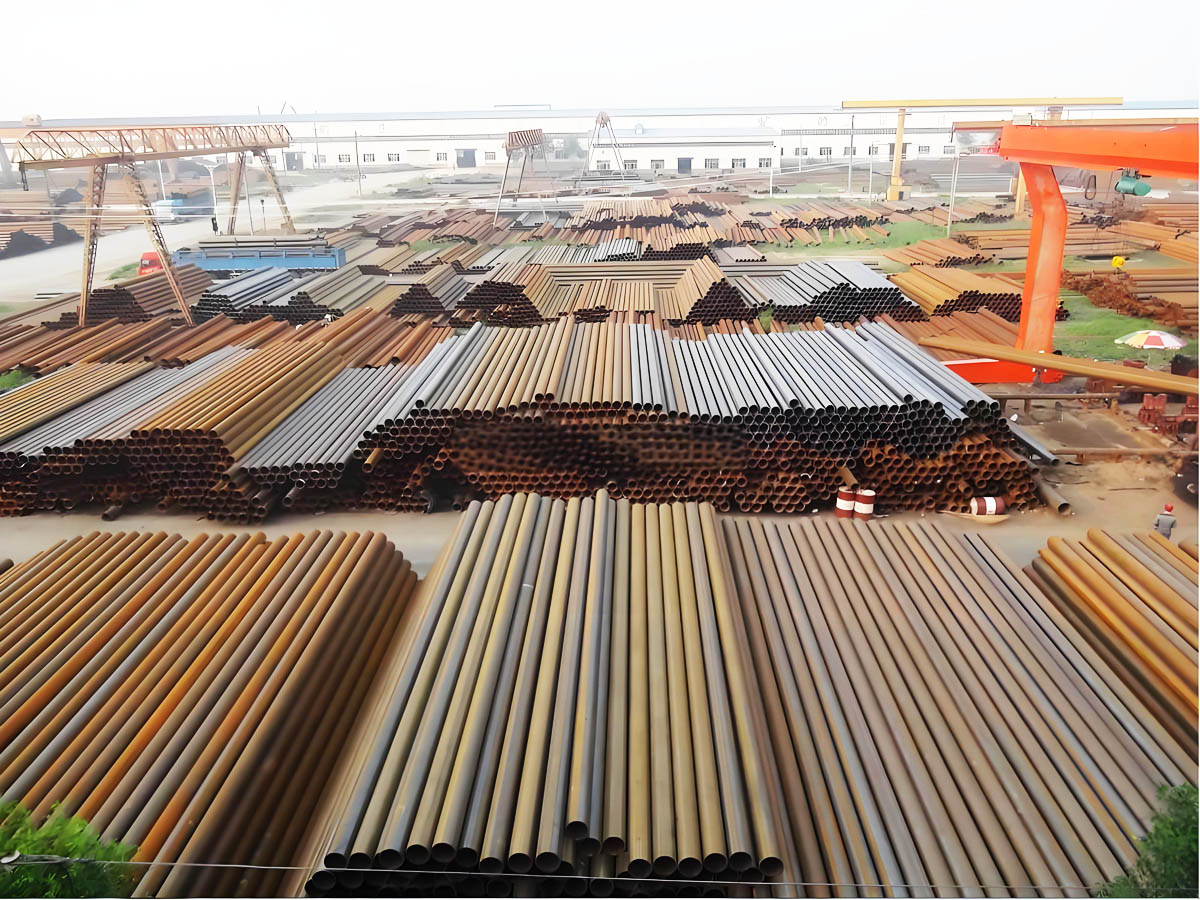

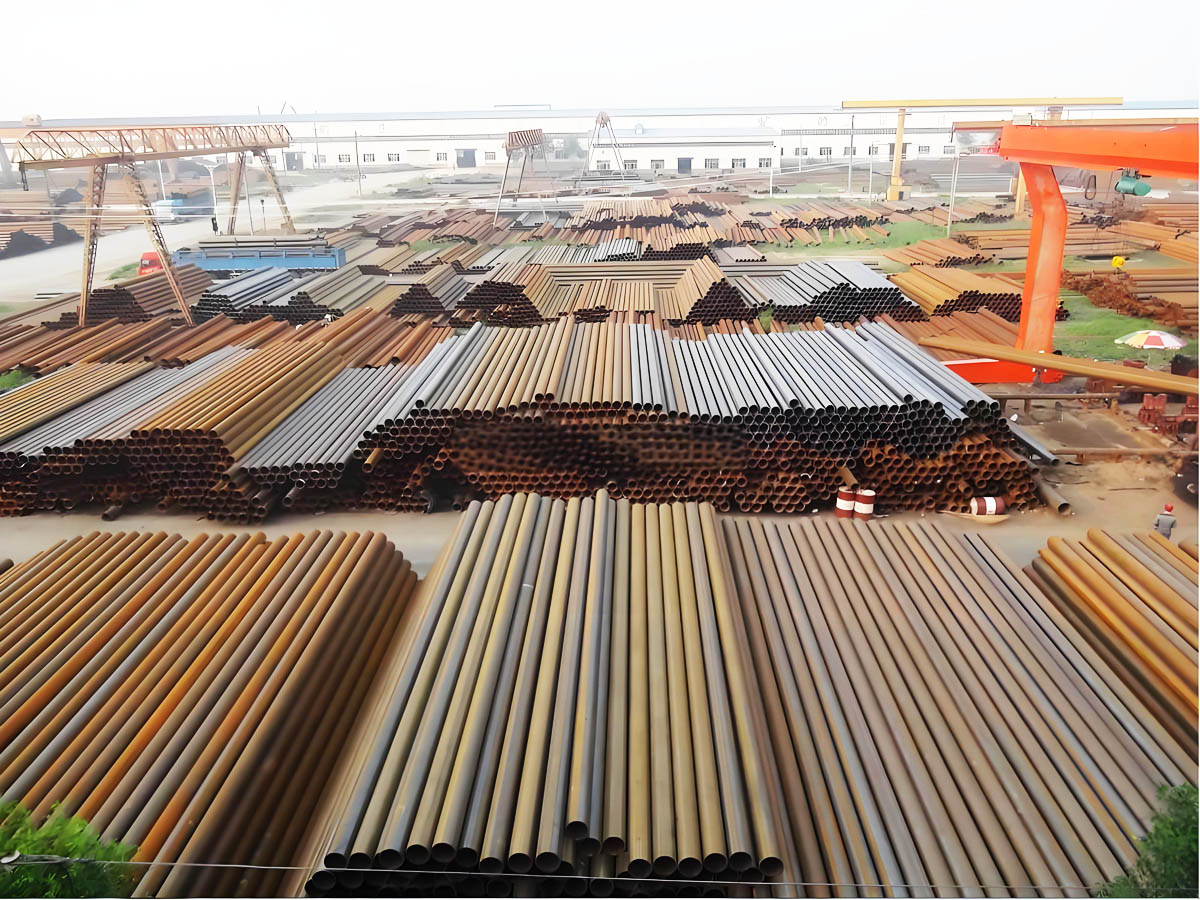

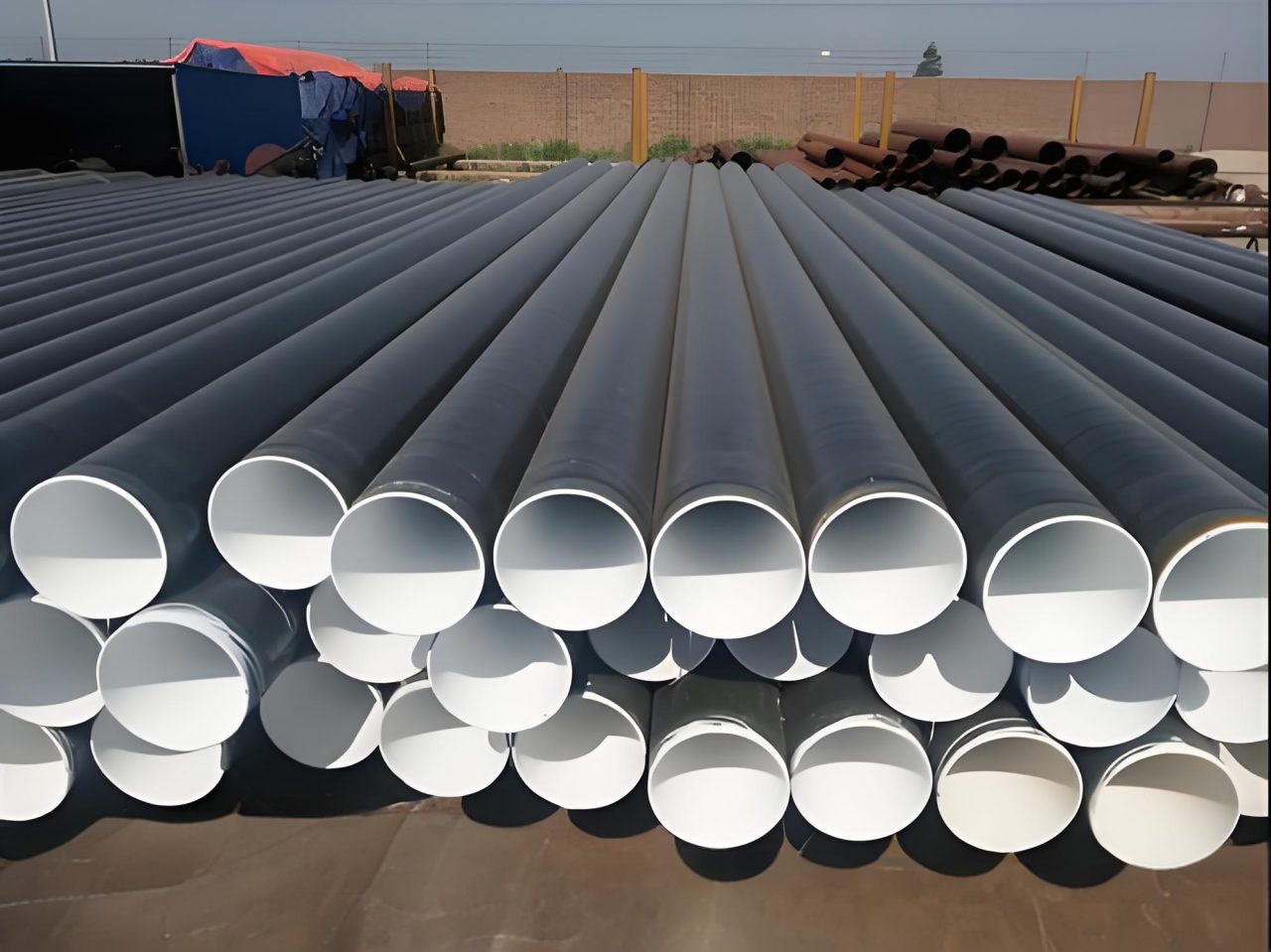

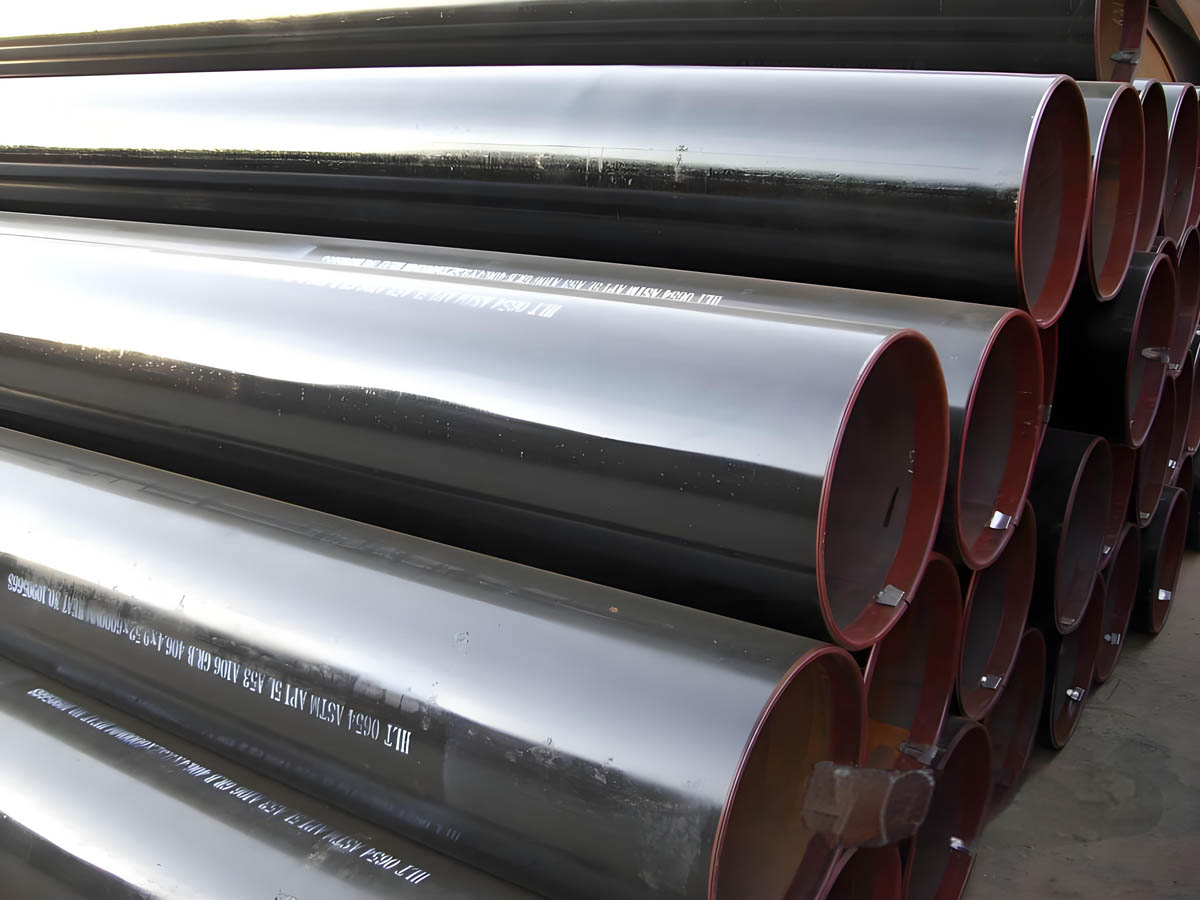

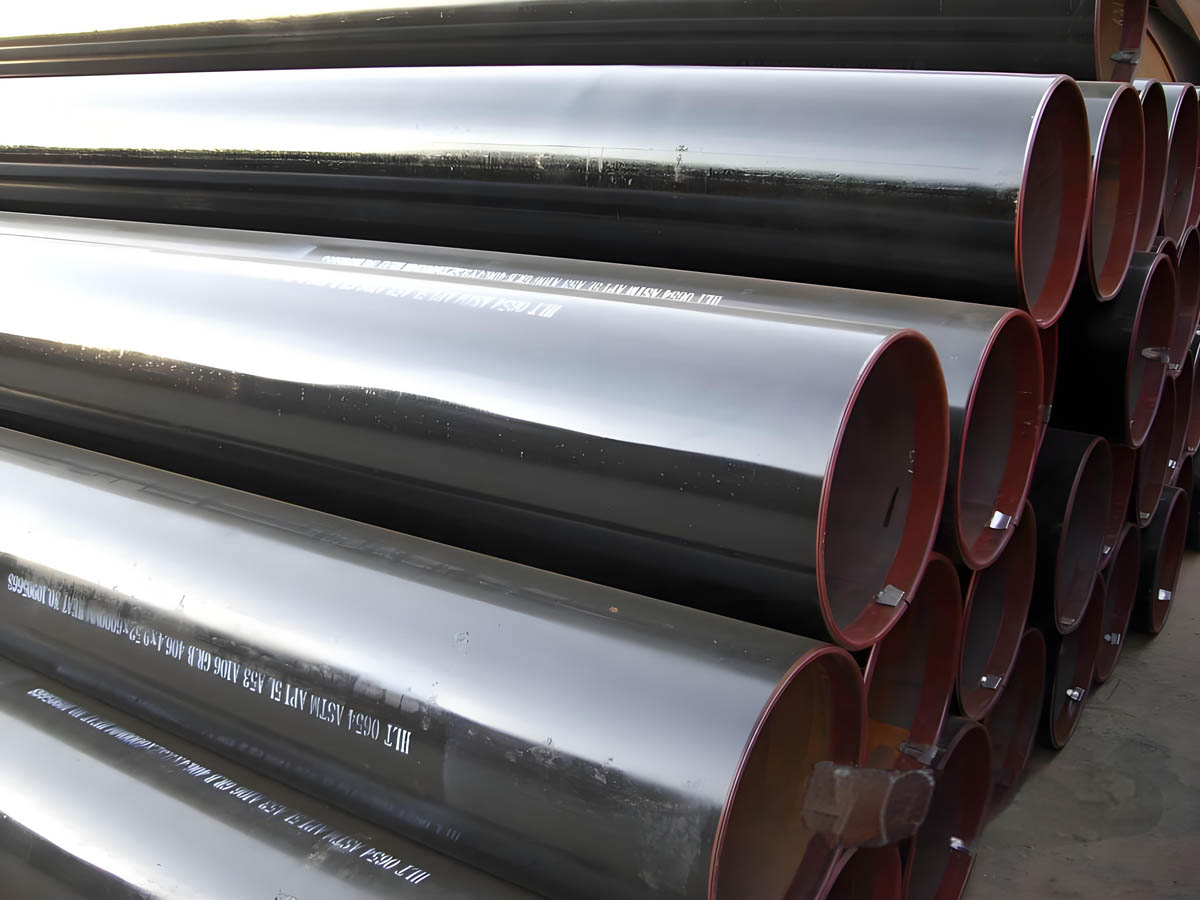

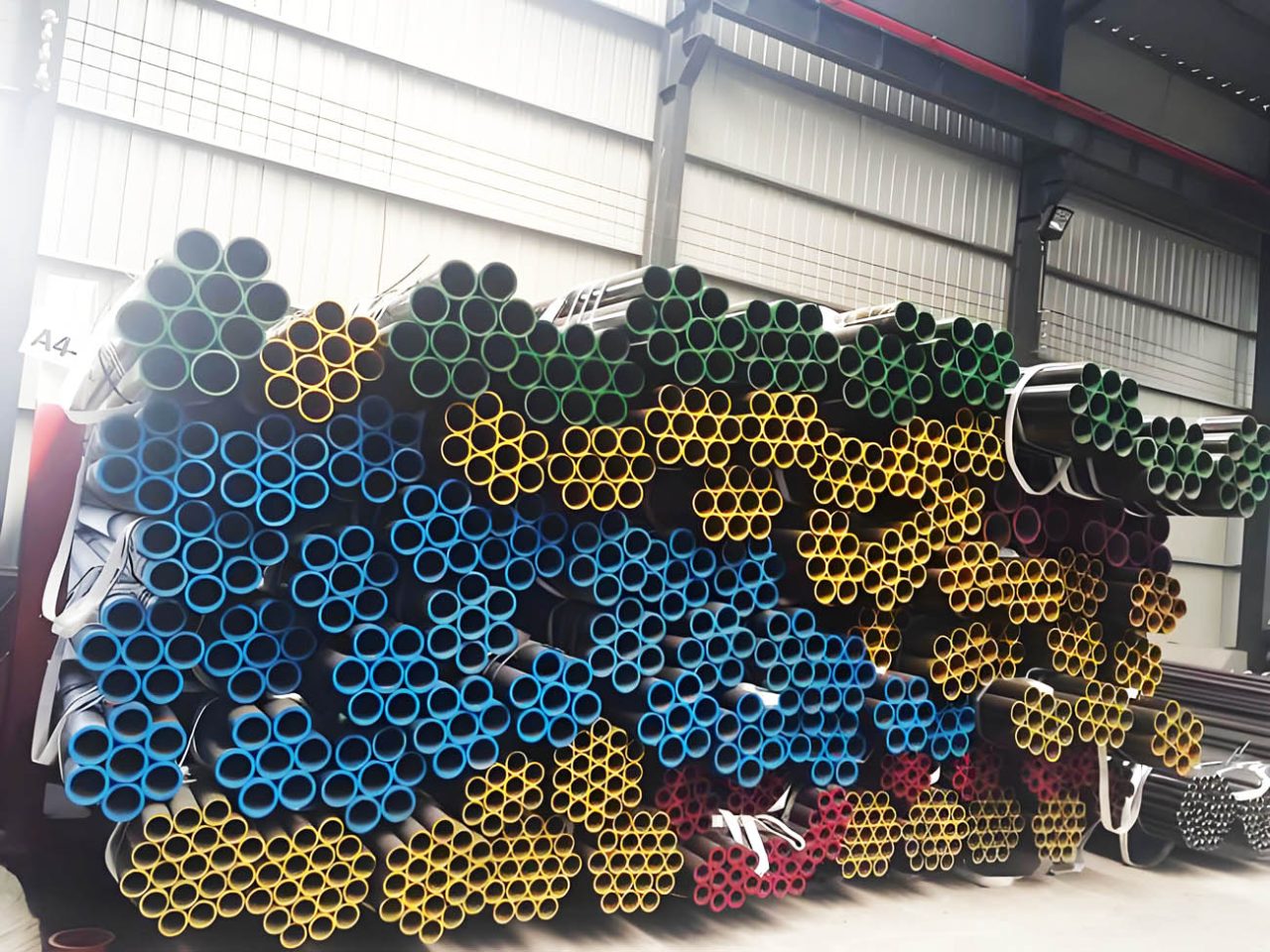

ASTM A252 Tubing Applications: Tubular steel pipe piles, structural support piles, cast-in-situ concrete piles. Products: Carbon steel seamless pipes, black steel pipe, stainless steel tubes, coating steel pipes.

ASTM A252 Tubing Applications: Tubular steel pipe piles, structural support piles, cast-in-situ concrete piles. Products: Carbon steel seamless pipes, black steel pipe, stainless steel tubes, coating steel pipes.

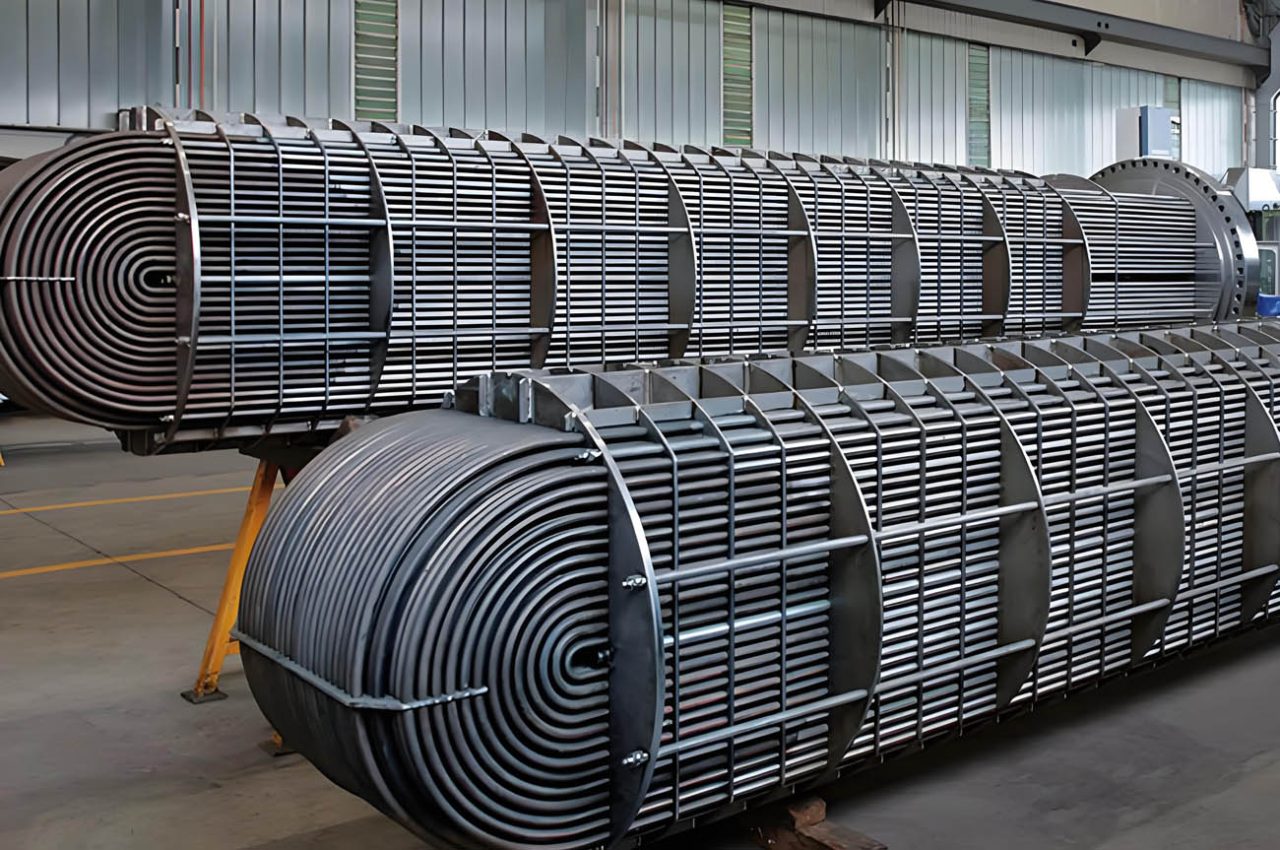

ASTM A178 standard referes to electric-resistance-welded tubes with minimum-wall-thickness. Materials are carbon steel and carbon-manganese steel, ASTM A178 pipe and tube is to be used in boiler tubes, boiler flues, superheater flues and safe ends. Steel Grades A (low-carbon steel), C (medium-carbon steel), or D (carbon-manganese steel). Manufacturing processes must include heat treatment, welding after cooling. Crush test shall be performed if required by customer.

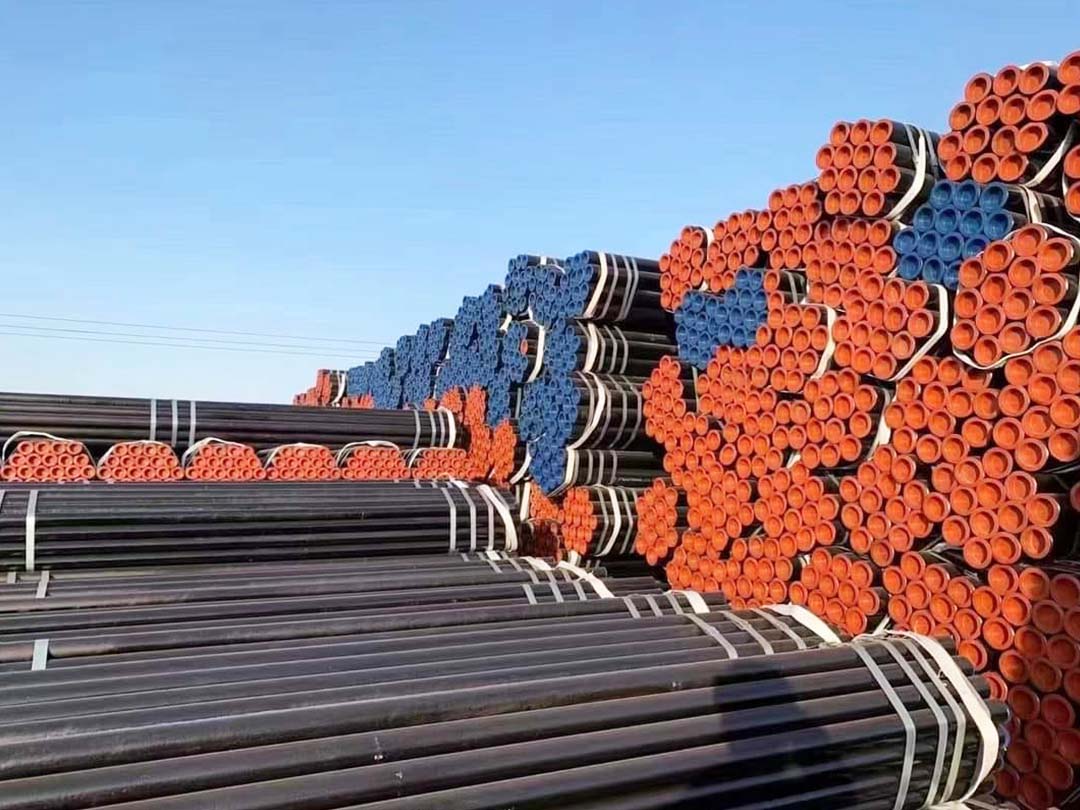

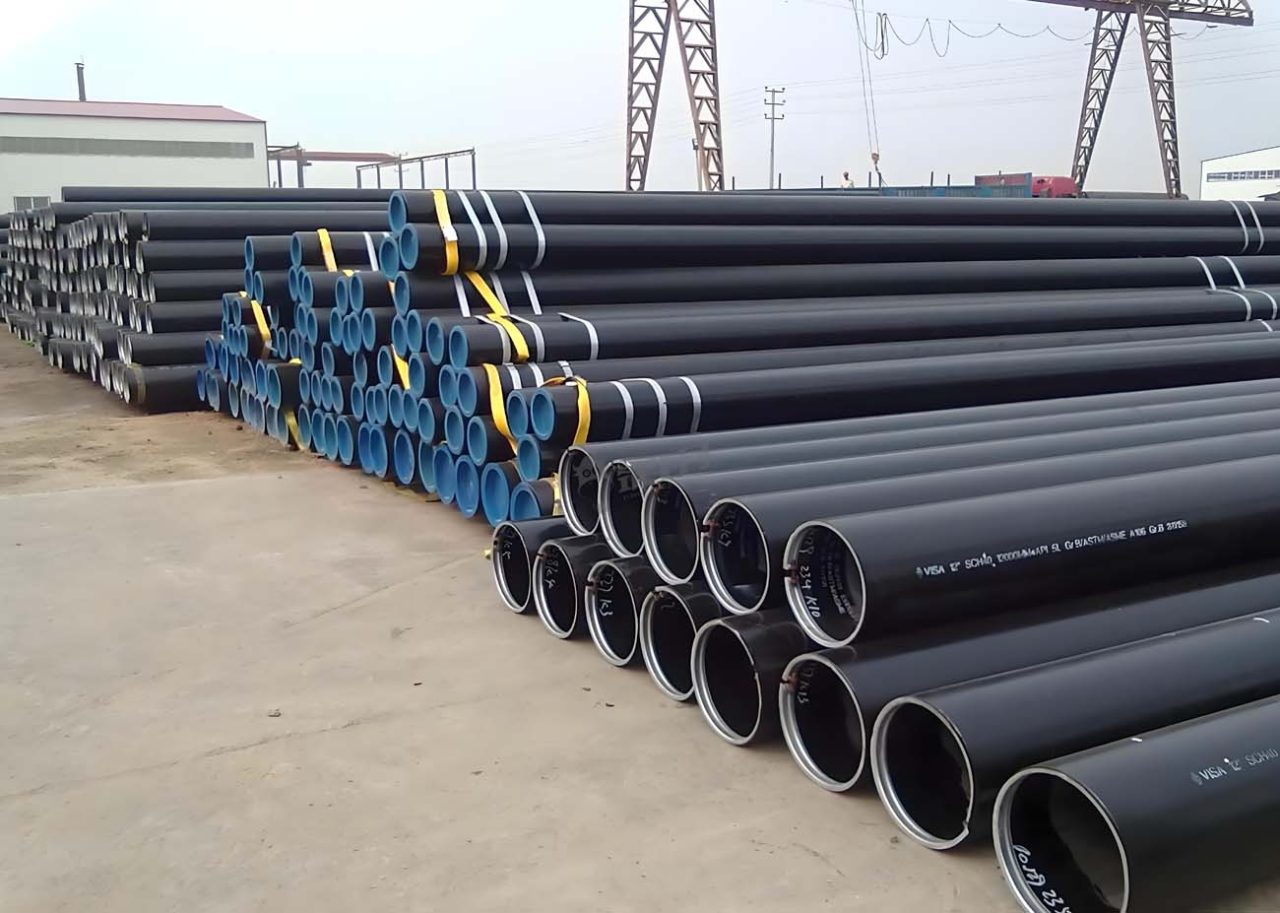

Conclusion HFI steel pipes are a reliable and efficient choice for a wide range of applications, offering high-quality welds and consistent dimensions. Their cost-effectiveness and versatility make them a popular option in industries such as oil and gas, construction, and automotive.

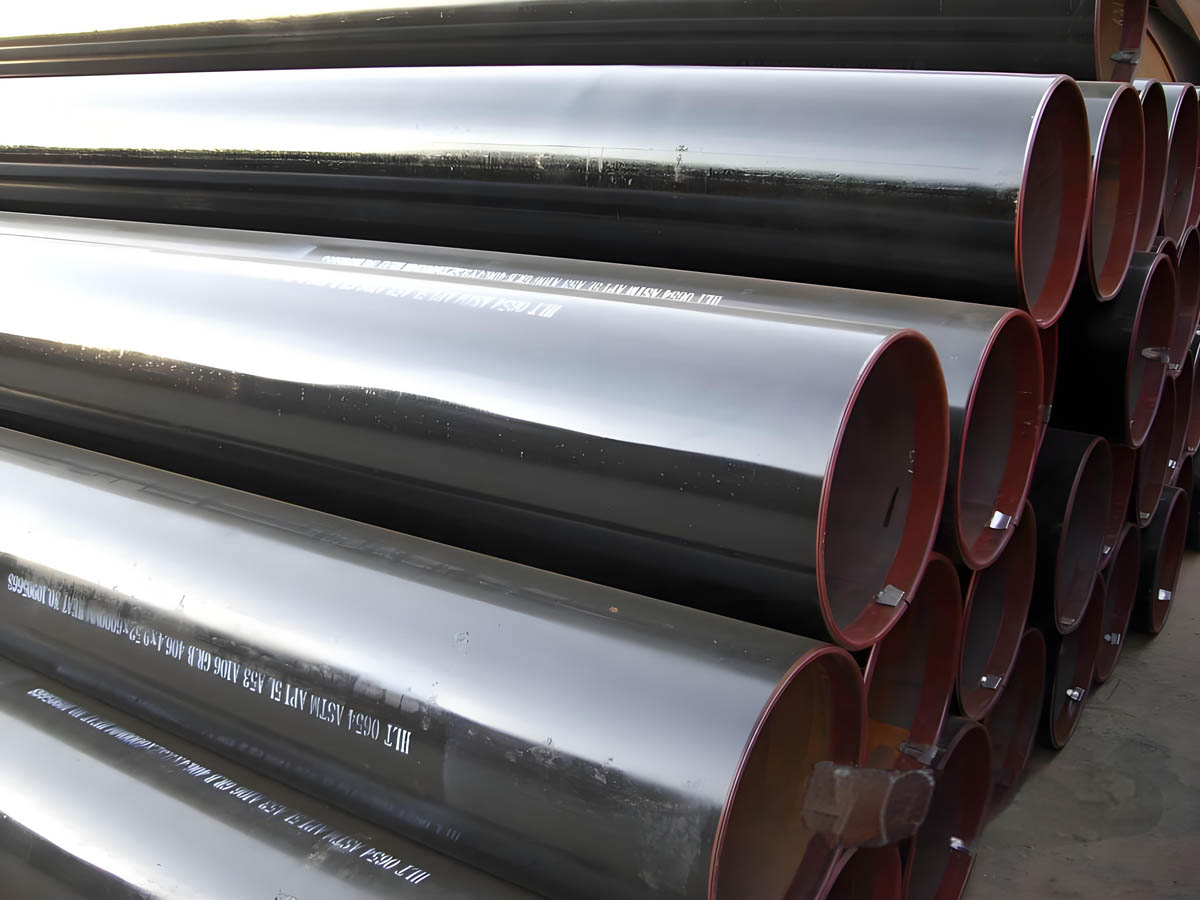

EFW steel pipes are a reliable choice for applications that require large-diameter, high-strength pipes with excellent weld integrity. Their manufacturing process ensures robust and consistent quality, making them suitable for demanding industries like oil and gas, petrochemicals, and large-scale water supply systems. While they may come at a higher cost compared to ERW and HFW pipes, their superior mechanical properties and ability to handle high-pressure conditions justify their use in critical applications.

Both ERW and HFW steel pipes have their unique advantages and applications. ERW pipes are suitable for general purposes where cost-effectiveness and adequate strength are required. In contrast, HFW pipes are preferred for applications demanding superior weld quality and higher strength, especially in the oil and gas industry and high-pressure fluid transport systems. The choice between ERW and HFW will depend on the specific requirements of the project, including the mechanical stress, pressure conditions, and budget constraints.

ERW steel pipes are an essential component in various industrial applications, providing a reliable and economical solution for fluid transportation and structural uses. The specifications provided ensure that these pipes meet stringent industry standards and customer requirements.

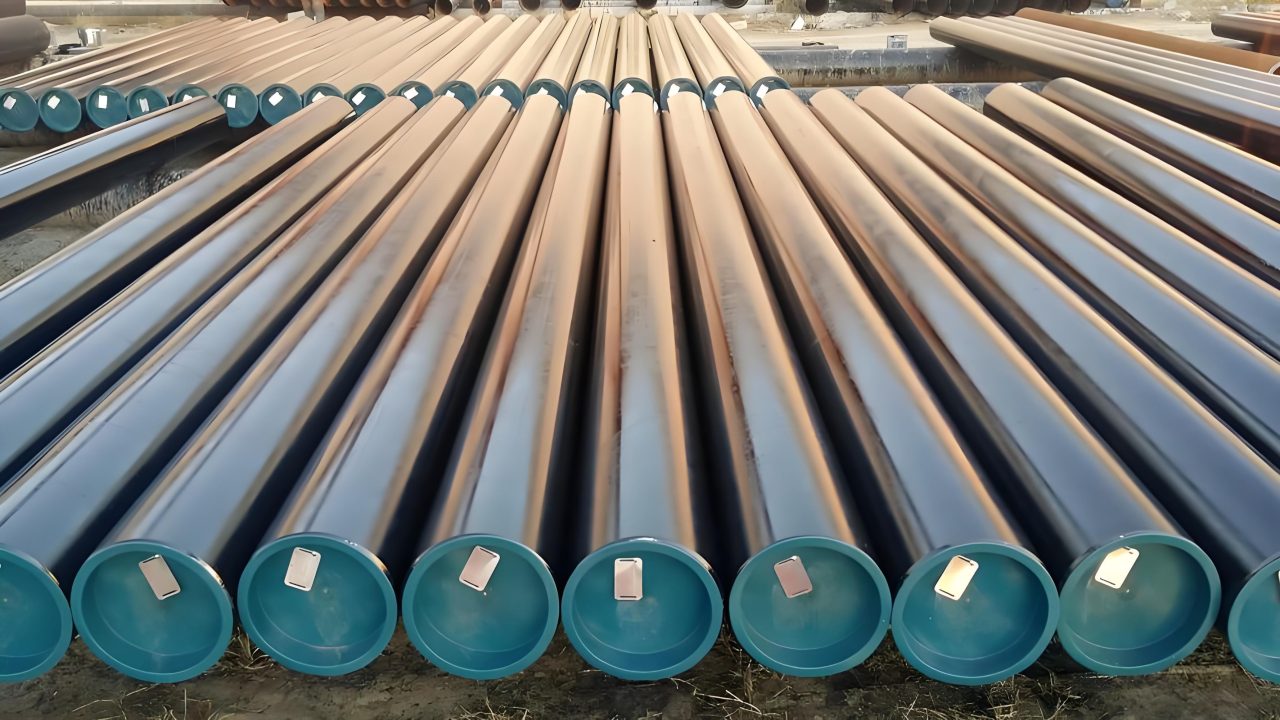

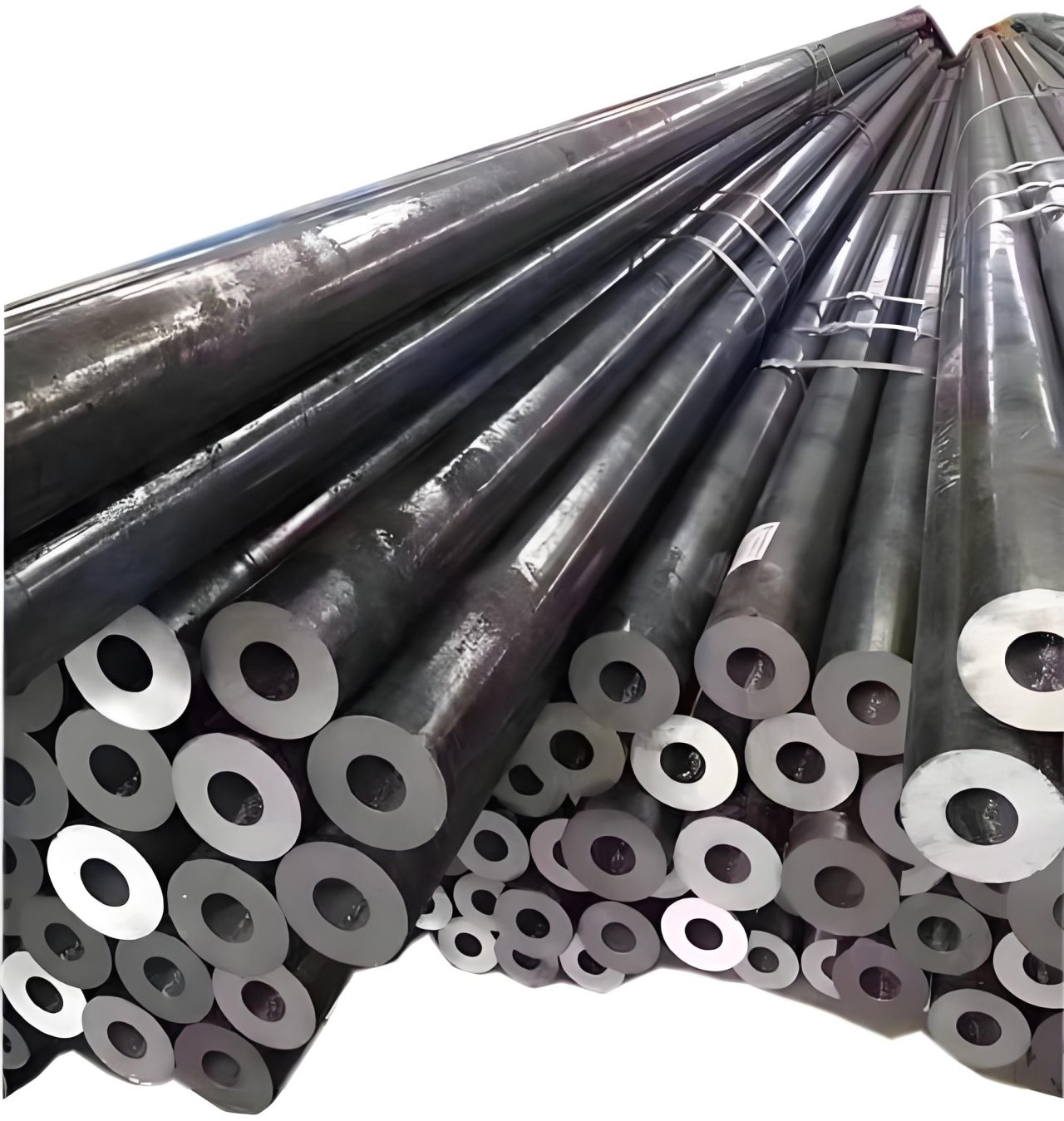

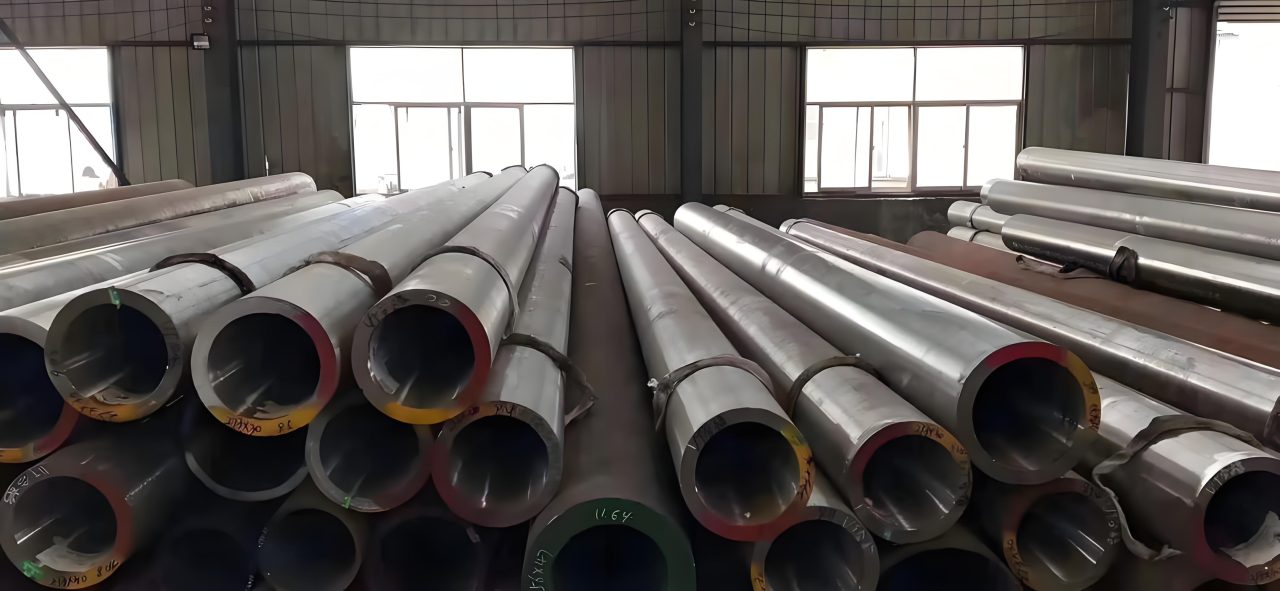

ASTM A519 is the standard specification for seamless carbon and alloy steel mechanical tubing. These tubes are used for mechanical and pressure applications as well as for transporting steam, water, and gas. ASTM A519 pipes are suitable for bending, flanging, and similar forming operations, and for fusion welding.

Using ASTM A192 seamless boiler pipes in power plants offers numerous advantages, including high-pressure and high-temperature resistance, seamless construction, excellent mechanical properties, and compliance with strict quality standards. These benefits contribute to the efficiency, safety, and reliability of power plant operations, making ASTM A192 pipes a preferred choice for critical boiler applications.

ASTM A335, also known as ASME SA335, is the standard specification for seamless ferritic alloy-steel pipe intended for high-temperature service. Below are the detailed chemical compositions, mechanical properties, and specifications for the most commonly used grades of ASTM A335 pipes.

ASTM A106 seamless steel pipes are a reliable choice for high-temperature applications due to their robust mechanical properties and versatile manufacturing process. They are essential in various industrial sectors, ensuring durability and performance under extreme conditions.