To sum up, Nickel 200's surface treatment technology includes methods such as pickling, bright annealing and polishing surfaces. These technologies have their unique advantages and room for improvement in different application scenarios.

admin

Nickel 200 (UNS N02200/WS 2.4060) is a high-purity nickel alloy pipeline material. It performs excellently in corrosive media treatment, electronics and aerospace, but its high-temperature applications need to be carefully selected. Its welding pipe standard ASTM B725 clearly defines the size and process requirements. The supplier needs to match the carbon content (select Nickel 200 or 201) and surface treatment method according to the specific working conditions.

Perforated casing pipes are widely used in both oil & gas and water well applications. They play a crucial role in enabling efficient fluid flow, protecting the wellbore, and ensuring the overall longevity of the well. The pipe’s perforations (holes) allow for controlled inflow or outflow of fluids while preventing the collapse of the wellbore, which can be caused by external pressures. This article provides a comprehensive look at Perforated Casing Pipes, including their specifications, materials, types, mechanical properties, and applications in the oil, gas, and water well industries.

The choice between Inconel® X-750 (UNS N07750) and Nickel Alloy 600 depends largely on the specific requirements of the application: Choose Inconel X-750 for high-stress, high-temperature applications where mechanical strength, fatigue resistance, and creep resistance are critical (e.g., aerospace, nuclear, and gas turbines). Choose Nickel Alloy 600 for versatile corrosion resistance in general-purpose applications or where fabrication and cost-efficiency are more important (e.g., chemical processing, marine, and heat exchangers).

Hastelloy C276 alloy steel pipes, produced under ASTM B622 UNS N10276 standards, are indispensable in industries that demand high corrosion resistance and durability. With its exceptional properties, wide-ranging applications, and long lifespan, this material remains a top choice for critical applications. Investing in Hastelloy C276 ensures reliability and performance, even in the most challenging environments.

Hastelloy C-276 stands out as one of the most versatile and corrosion-resistant alloys available today. Its unique properties make it indispensable in industries where performance and reliability are paramount. From resisting aggressive acids in chemical plants to enduring the harsh conditions of marine environments, Hastelloy C-276 has proven its worth time and again. While its high cost and fabrication challenges may pose limitations, the benefits it offers far outweigh these drawbacks for critical applications.As global industries continue to push the boundaries of innovation, Hastelloy C-276 will remain a cornerstone material for demanding environments, ensuring safety, efficiency, and durability for years to come.

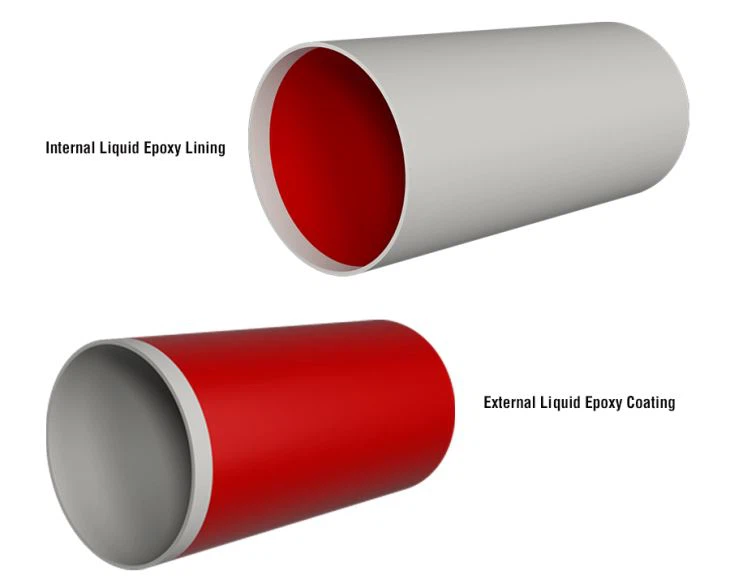

Liquid-epoxy coatings and linings are essential for protecting steel water pipes and fittings in water infrastructure systems. From their superior corrosion resistance to their adaptability for various applications, these coatings ensure the long-term performance and safety of pipelines. By adhering to proper application techniques, inspection protocols, and industry standards, project managers and engineers can maximize the benefits of epoxy coatings. Whether you're working on a potable water system or a wastewater project, liquid-epoxy coatings provide a durable, cost-effective, and environmentally friendly solution to meet the demands of modern water infrastructure.

Epoxy-coated steel pipes are essential for ensuring the durability, safety, and efficiency of water supply, drainage, and dredging systems. By complying with international standards and offering superior corrosion resistance, epoxy-coated pipes deliver exceptional performance in harsh operating conditions.

Duplex 2205 (UNS S32205) steel pipe is a high-performance material that offers a blend of strength, corrosion resistance, and durability. Ideal for use in challenging environments like oil and gas, marine applications, and chemical processing, it outperforms standard austenitic steels in many areas. However, its higher cost and welding challenges may make it less ideal for less demanding applications.

The CFD analysis of water flow inside buttweld elbow pipes reveals that the normal-edged elbow pipe outperforms the sharp-edged elbow pipe in terms of flow efficiency, energy consumption, and structural integrity. Key findings include: