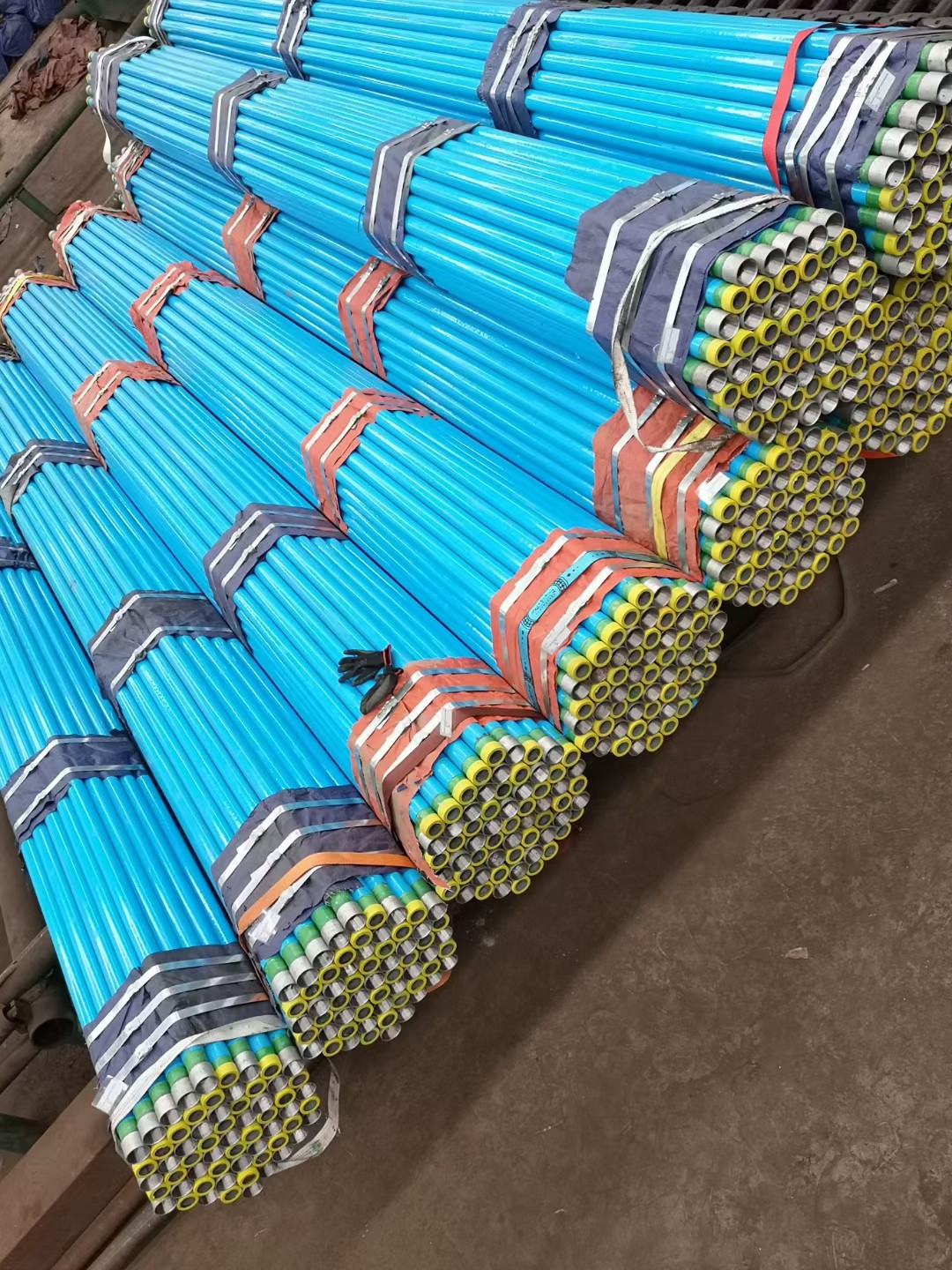

hot dipped galvanized tubes Scaffolding pipes,pre galvanized steel tubes,GI pipes and tubes, hot dipped pipes and tubes play more good role on the outdoor using such as bridge pipes, warehouse, street lamp, and telegraph poles, and also for the liquid pipes, useful widely. pre-galvanized steel pipes used in Construction / building materials steel pipe, Scaffolding pipe, Solar structure component steel pipe, Fence post steel pipe, Greenhouse frame steel pipe.

admin

Each type of scaffold tube and pipe offers distinct advantages and is selected based on the specific requirements of the construction project, including factors such as load capacity, environmental conditions, and budget constraints. By choosing the appropriate material, construction professionals can ensure the safety and efficiency of their scaffolding systems.

Scaffolding Pipe is a vital component of the construction industry, providing safe access to elevated work areas and supporting the efficient completion of projects. Understanding the necessity of Scaffolding Pipe, how it is assembled, the materials used in its construction, and the processes involved in inspecting it for safety is essential for ensuring the safety and success of construction projects. By adhering to best practices and safety standards, construction professionals can minimize risks and create a safe working environment for all involved.

The design of application pressure for chemical pipelines is influenced by a combination of chemical properties, flow rate requirements, friction loss, material selection, and environmental conditions. By carefully considering these factors, engineers can ensure the safe and efficient transport of chemical substances, minimizing risks and maintaining the integrity of the pipeline.

Casing pup joints are essential components in the construction and operation of oil and gas wells. They allow for precise adjustment of the casing string length, ensuring proper placement of downhole equipment and alignment with wellhead components. Selecting the appropriate pup joints based on diameter, material grade, and thread type is crucial for maintaining well integrity, safety, and efficient operation.

Couplings are short lengths of pipe used to connect 2 joints of tubing or casing. They come with painted colour codes on their external surface to indicate their grades. Couplings are manufactured according to API 5CT and 5B specifications.

Drill pipe is a steel pipe with thread at the end, which is used to connect the surface equipment of the drilling rig to the drilling and grinding equipment or the bottom hole equipment at the bottom of the drilling. Drill pipe can be divided into three categories: kelly, drill pipe and heavy drill pipe. Drill collar is located at the bottom of the drill string and is the main component of the lower drill tool assembly. Its main feature is that the wall thickness is larger, and it has greater gravity and rigidity. In order to facilitate tripping work, elevator grooves and slip grooves can be processed on the outer surface of the inner thread of the drill collar. Drill collars are generally divided into three types: spiral drill collars, non-magnetic drill collars, and integral drill collars.

Slotted pipe are used for oil and gas wells. Steel casing pipes and tubing are applied to furnishing and installing cased tunnels, where they indicate to pass other utilities or obstructions without open excavation. Steel casing pipes and tube have smooth wall and a minimum yield strength of 35,000 psi. Corrosion-proofing water-based paint is applied on the outside pipe surface to protect against atmospheric corrosion during transportation and storage.

Petroleum special pipes are mainly used for drilling oil and gas wells and oil and gas transportation. Oil casing is mainly used to support the wellbore during driling and after completion to ensure the normal operation of the wholewell, Oil casing is the lifeline to maintain oil well operation. Because of the different aeolodical conditions.the stress state of underground is complex, and the comprehensive action of tension, compression, bending and torsion stresses acts on the pipe body, which puts forward higher requirements for the quality of casing itself.

oil casing And Seamless Pipe, Seamless 5ct Petroleum Casing Pipe, Petroleum Casing Pipe, Petroleum Tubing, Oil Casing Pipe, Casing & Tubing, Smls Steel pipes And Casing Tubing, API 5ct Oil Casing Pipe, API 5ct Oilfield Tubing, API 5CT V150 Petroleum Casing Pipe, Grade V150 Oil Well Drilling Tube