By understanding the differences in chemical composition, mechanical properties, heat treatment, applications, and costs, operators can choose the most appropriate casing pipe grade to ensure well integrity and operational efficiency.

Blog

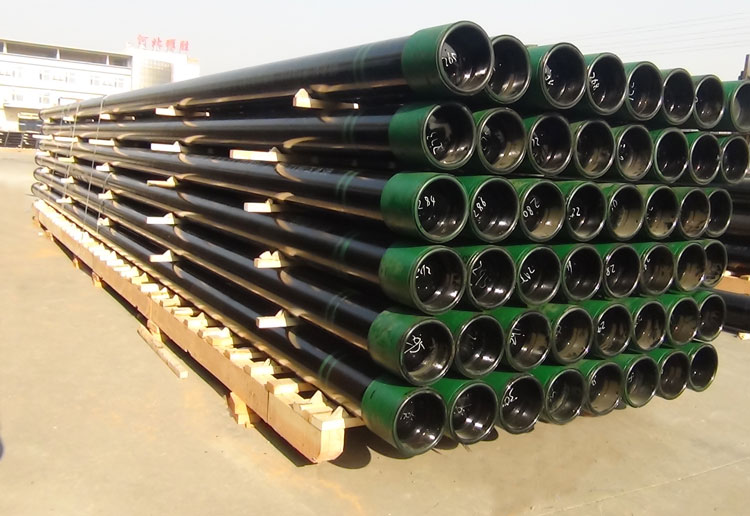

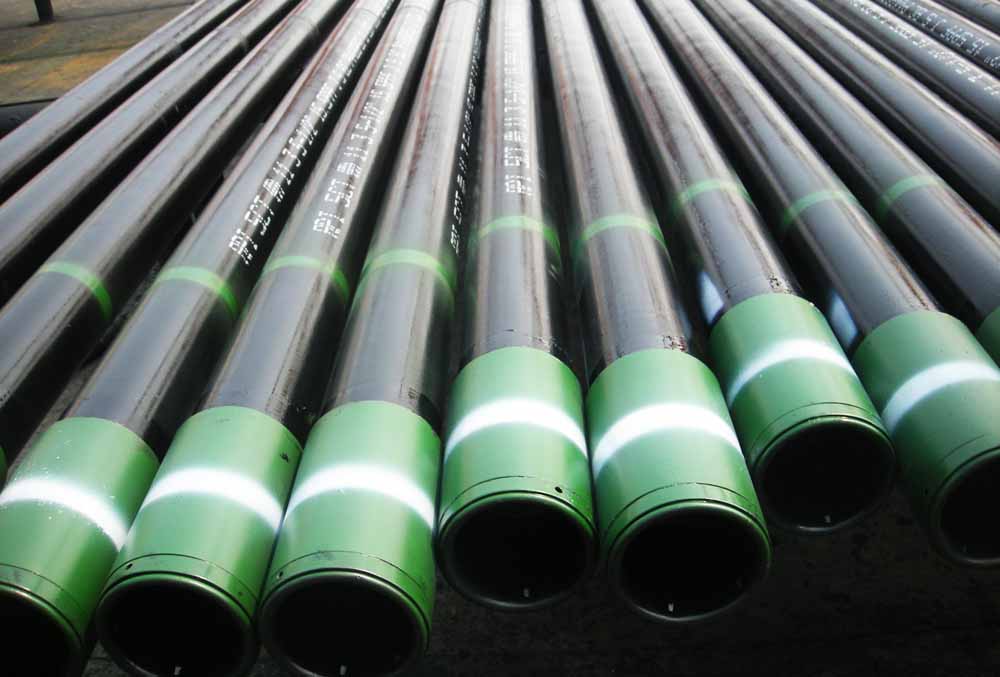

N80-1 and N80Q casing pipes are crucial components in the drilling and production of oil and gas wells. They are manufactured to meet API 5CT standards, ensuring quality, performance, and reliability. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, N80-1 and N80Q casing pipes deliver dependable performance in various drilling and production environments. Their high-strength properties and specific chemical compositions make them suitable for challenging operational conditions, providing robustness and reliability for wellbore integrity.

L80 casing tubing is a crucial component in the drilling and production of oil and gas wells. It is manufactured to meet API 5CT standards, ensuring quality, performance, and reliability. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, L80 casing tubing delivers dependable performance in various drilling and production environments. Each type (L80-1, L80 13Cr, L80 9Cr) offers specific properties tailored to different operational needs, providing versatility and robustness in challenging conditions.

M65 casing pipe is a crucial component in the drilling and production of oil and gas wells. It is manufactured to meet API 5CT standards, ensuring quality, performance, and reliability. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, M65 casing pipe delivers dependable performance in various drilling and production environments.

API 5CT K55 is a pipe grade specified by the American Petroleum Institute. API 5CT K55 is a type of well casing that is typically used in well drilling operations. The casing and tubing are OCTG (oil country tubular goods) that are used to form the walls of the well. The steel pipe is placed in the well and held in place by cement. The cement helps to protect the well from collapse and keeps the well fluids from escaping. API 5CT K55 is a popular choice for well drilling because it is durable and can withstand high temperatures and pressures.

The American Petroleum Institute specification API 5CT J55 Pipe is designed for use in the oil and gas industry. API 5CT J55 is a commonly used petroleum casing pipe material. It is produced according to the API 5CT standard and used in a variety of well types, both oil and natural gas. The main purposes of using casing or tubing are to protect the wellbore from collapse and to provide a conduit for well fluids. The casing is placed in the well first, followed by tubing, which is often smaller in diameter and thus can be nested inside the casing. Both casing and tubing must be made from strong materials that can withstand the high pressures and temperatures encountered deep underground. API 5CT J55 meets these requirements and is, therefore, an excellent choice for OCTG (oil country tubular goods) applications. It is typically produced as seamless steel pipe, but can also be procured in welded form. API 5CT J55 has a relatively high yield strength and good fatigue resistance, making it an ideal choice for high-pressure, high-load applications such as petroleum products.

H40 casing steel pipes are essential components in the drilling and production of oil and gas wells. These pipes are manufactured to meet API Spec 5CT standards, ensuring quality, performance, and reliability. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, H40 casing pipes deliver dependable performance in various drilling and production environments.

ASTM A358 stainless steel pipes offer a reliable solution for high-temperature and general corrosive service applications. These pipes are produced to meet specific chemical composition and mechanical property requirements, ensuring performance and durability. The specification provides flexibility in manufacturing and testing, allowing for a balance between cost and performance. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, ASTM A358 pipes deliver dependable performance in a variety of industrial applications.

ASTM A632 stainless steel pipes offer a reliable solution for low to moderate temperature and general corrosive service applications, particularly where a superior surface finish is required. These pipes are produced to meet specific chemical composition and mechanical property requirements, ensuring performance and durability. The specification provides flexibility in manufacturing and testing, allowing for a balance between cost and performance. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, ASTM A632 pipes deliver dependable performance in a variety of industrial applications.

410S SMLS Pipes ASTM A268 TP410S Stainless Steel Seamless Tubes AISI Type 410S is a non-hardenable, low carbon modification of Type 410, providing moderate strength with moderate corrosion resistance. The low carbon content and a small titanium addition minimizes austenite formation at high temperatures, thereby restricting the alloy's ability to harden. The result is a soft, ductile condition when the material is rapidly cooled from above the critical temperature. The result is a soft, ductile condition when the material is rapidly cooled from above the critical temperature. The 410S stainless alloy is completely ferritic.