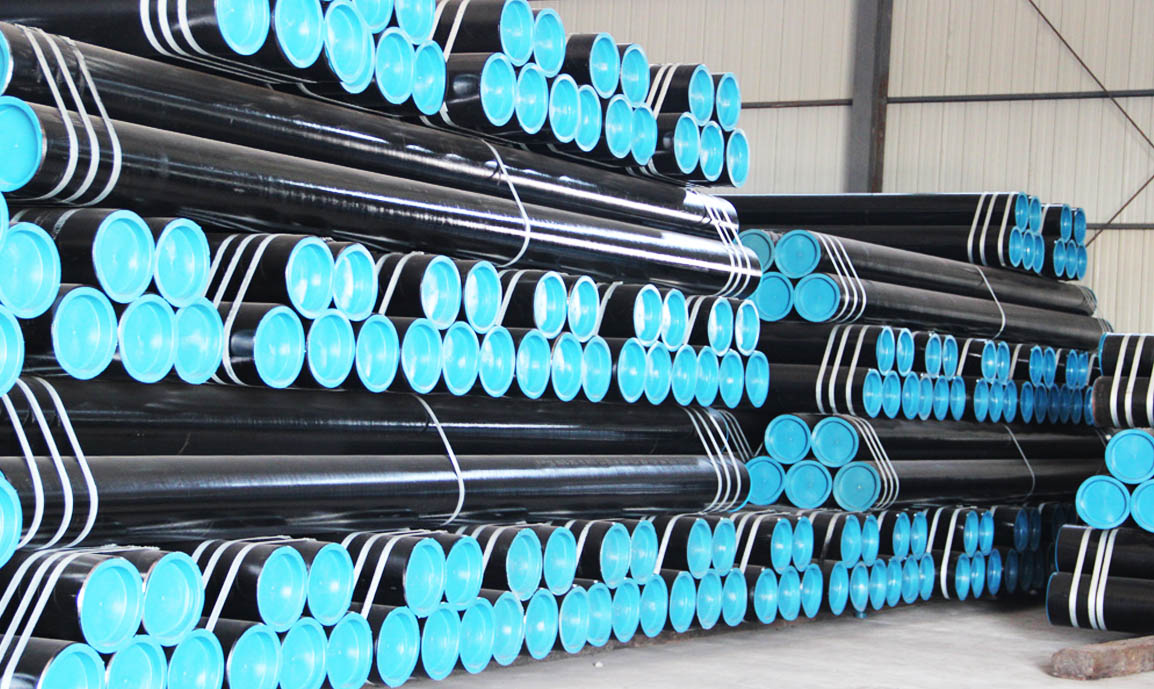

Boiler Steel Pipes

Boiler Steel Pipes: An In-Depth Overview

Boiler Steel Pipesare specialized pipes used within boilers to heat water and produce steam. They are essential components in various industries, ensuring the efficient and safe operation of thermal systems. This guide will explore the types, features, specifications, and quality considerations of Boiler Steel Pipes.

Types of Boiler Steel Pipes

Water-Tube Boilers

In water-tube boilers, water circulates inside the tubes, which are heated externally by hot gases produced by the furnace. These boilers are designed to handle high pressures and temperatures, making them suitable for power plants and industrial applications.

Fire-Tube Boilers

In fire-tube boilers, hot gases pass through one or more tubes, heating the water surrounding them by thermal conduction. These boilers are typically used for low to medium pressure applications and are common in small-scale industries and heating systems.

Pressure Classifications

Boiler Steel Pipesare classified based on the operating pressure:

Medium-Pressure Boiler Steel Pipes

- Operating Temperature: Less than 450°C

- Manufacturing Process: Typically hot-rolled or cold-drawn

- Applications: Lower pressure environments, often found in heating systems and industrial boilers.

High-Pressure Boiler Steel Pipes

- Operating Conditions: Extreme temperatures and pressures

- Requirements: High tensile strength, resistance to oxidation and corrosion, superior structural stability

- Applications: Power plants, petrochemical industries, and other high-stress environments

Material and Construction

Boiler Steel Pipes are welded and typically made from steel, providing resistance to various types of wear and tear. The seam that runs along their length helps to prevent leaks, enhancing their durability and reliability.

Common Materials

- Carbon Steel: ASTM A106 Gr.B, ASTM A53 Gr.B, ASTM A210

- Alloy Steel: ASTM A335 P11, P22, P91, 15CrMoG, 12Cr1MoVG

- Stainless Steel: ASTM A213 T11, T22, T91, TP304, TP316

Key Properties

High-Temperature Resistance

Boiler Steel Pipes, especially fire-tube types, must withstand temperatures reaching several hundred degrees Celsius or higher. They should maintain their performance without losing strength or developing cracks.

High-Pressure Resistance

To improve efficiency, Boiler Steel Pipesoften operate under pressurized conditions. They must resist high pressures without rupturing or exploding.

Corrosion Resistance

Boiler Steel Pipes are exposed to various environments and substances that can alter their chemical properties. Good corrosion resistance is crucial, particularly for water-tube boilers, which may experience scaling.

Quality Assurance

ABTER STEEL PIPE maintains stringent quality control throughout the manufacturing process, from steelmaking to the final tube fabrication. Key elements of their quality assurance system include:

- Independence of the Quality Assurance Department: Ensures unbiased quality control.

- Standardization of Tasks: Facilitates unified manufacturing and quality processes.

- Inspector Qualification System: Ensures that all inspectors are qualified and tasks are standardized.

- Nondestructive Tests: Mandatory tests and inspections are conducted, with all items undergoing nondestructive testing during final inspection.

- Periodic Calibration Systems: Regular calibration of gauges and testers to maintain inspection accuracy.

Selecting High-Quality Boiler Steel Pipes

Steps to Ensure Quality

- Cross-Section Examination: A high-quality seamless boiler tube will have a smooth cross-section without bumps or imperfections.

- Density Check: Determine the tube’s density to assess the percentage of contaminants. Avoid low-density pipes.

- Surface Inspection: A smooth and even surface indicates high quality, whereas a rough and uneven surface suggests poor quality.

Features of Boiler Steel Pipes

Boiler Steel Pipes require exceptionally high quality, diverse steel grades, and dimensions suitable for various applications. ABTER STEEL PIPE’s Boiler Steel Pipes meet these standards through an integrated production system and stringent quality control from raw materials to finished products. Continuous research and development ensure the introduction of new materials and products to meet evolving needs.

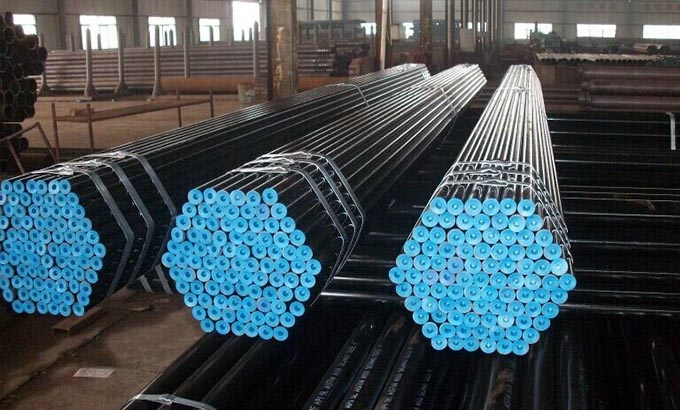

Boiler Steel Pipe: A Comprehensive Guide

Introduction

Boiler steel pipes are specialized tubes designed to withstand high pressures and temperatures in various applications, particularly in boilers, heat exchangers, and power plants. These pipes are critical components in ensuring the efficiency and safety of thermal systems. In this guide, we will explore the various aspects of boiler steel pipes, including their types, specifications, standards, materials, and applications.

Types of Boiler Steel Pipes

Boiler steel pipes can be broadly categorized into two types based on their manufacturing process:

- Seamless Boiler Pipes: Made without a weld seam, providing higher strength and resistance to pressure and temperature variations.

- Welded Boiler Pipes: Manufactured by welding the edges of steel plates, suitable for lower pressure applications compared to seamless pipes.

Specifications of Boiler Steel Pipes

Boiler steel pipes come in a variety of sizes, thicknesses, and lengths to meet specific requirements:

- Outer Diameter (OD): Typically ranges from 10mm to 1200mm.

- Wall Thickness: Varies from 1mm to 60mm depending on the application.

- Length: Standard lengths are 5.8m, 6m, 11.8m, and 12m, but custom lengths can also be produced according to requirements.

Materials

Boiler steel pipes are made from high-quality materials that can withstand high temperatures and pressures. Common materials include:

- Carbon Steel:

- ASTM A106 Gr.B

- ASTM A53 Gr.B

- ASTM A210

- Alloy Steel:

- ASTM A335 P11, P22, P91

- 15CrMoG

- 12Cr1MoVG

- Stainless Steel:

- ASTM A213 T11, T22, T91

- TP304

- TP316

Standards

Boiler steel pipes must comply with various international standards to ensure quality and performance. Some of the key standards include:

- ASTM Standards:

- ASTM A106: Standard specification for seamless carbon steel pipe for high-temperature service.

- ASTM A53: Standard specification for pipe, steel, black and hot-dipped, zinc-coated, welded and seamless.

- ASTM A335: Standard specification for seamless ferritic alloy-steel pipe for high-temperature service.

- ASTM A213: Standard specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes.

- ASME Standards:

- ASME SA106

- ASME SA210

- ASME SA335

- EN Standards:

- EN 10216: Seamless steel tubes for pressure purposes.

- EN 10217: Welded steel tubes for pressure purposes.

- DIN Standards:

- DIN 17175: Seamless steel tubes for elevated temperatures.

Applications

Boiler steel pipes are used in a variety of high-temperature and high-pressure applications, including:

- Boilers: Used in the construction of steam boilers and Boiler Steel Pipes in power plants and industrial facilities.

- Heat Exchangers: For transferring heat between fluids, typically in power plants, chemical industries, and oil refineries.

- Power Plants: Essential for the construction of superheaters, reheaters, and economizers.

- Petrochemical Industry: Used in refinery processes that require high-temperature and high-pressure conditions.

- Mechanical Engineering: Applied in the manufacturing of various pressure vessels and high-pressure equipment.

Key Properties

Boiler steel pipes must possess certain properties to perform effectively in their applications:

- High Strength: To withstand high pressures and mechanical stresses.

- Excellent Heat Resistance: To operate efficiently at high temperatures.

- Corrosion Resistance: Especially important for pipes exposed to steam and other corrosive substances.

- Durability: Ensuring long service life even in harsh conditions.

Conclusion

Boiler steel pipes are indispensable in industries that require the transfer of heat and fluids under high pressure and temperature conditions. Their reliability and performance are governed by stringent standards and specifications, ensuring safety and efficiency in critical applications like power generation, chemical processing, and mechanical engineering. By understanding the types, materials, standards, and applications of boiler steel pipes, industries can make informed decisions to meet their specific needs and ensure optimal performance.