Casing Pup Joints

Casing Pup Joints

Introduction

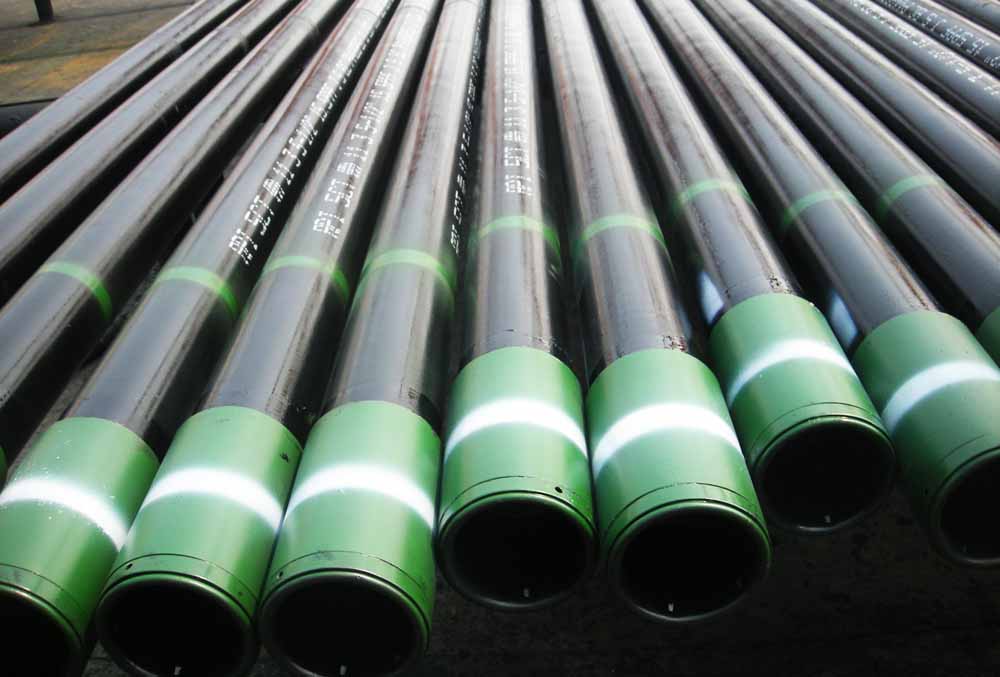

Casing pup joints are short lengths of casing used in the oil and gas industry to adjust the length of the casing string to fit specific well requirements. They are essential for ensuring the proper placement of casing collars, landing nipples, and other downhole equipment.

Overview

Pipe Type:Pup Joints,Casing Pup Joints,Tubing Pup Joints:NUE/EUE Tubing Pipe,Perforated Pup Joints, tubing Pup Joints

Outside Diameter :2-3/8”(60.3mm) – 4-1/2(114.60mm)

Lengths :2,3,4,6,8,10 12 ft

Casing Couping : 4-1/2” – 20′

Lengths:2,3,4,6,8,10 12 ft

Surface: Coating

Grades:J-55, N-80, N-80Q & T, L-80, P-110

Standard:API 5CT and 5B J55,K55,N80-1,N80-Q,P110, C95

Thread: BTC, LTC, STC

Special Service :Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156

Tubing Pup Joints:

•Sizes: 2 ⅜” – 4 ½”

•Weight: Standard or Requested Weights

•Typical Lengths: 1, 2, 3, 4, 6, 8, 10, 12′ (other lengths available upon request)

•Grades: J-55, N-80, L-80, P-110

•Connections EU (external-upset) and NU (non-upset)

•Options: Custom Sizes, Markings, Paint, Plating, and Inspection available on request

Casing Pup Joints:

•Outside Diameter: 4 ½” – 13 3/8″

•All weights available

•Typical Lengths: 1, 2, 3, 4, 6, 8, 10, 12′ (other lengths available upon request)

•Grades: H40, J55, K55, N80, L80 T95, C110, P110, Q125

•Connections: SC, LC, BC, Semi Premium, and Premium

•Options: Custom Sizes, Markings, Paint, Plating, and Inspection available on request

Pup Joint Options:

•Pin x Pin

•Pin x Pin with Couplings Loose

•Coupling Box x Pin with Couplings Hand Tight

•Coupling Box x Pin with Couplings Bucked-On

Definition

Casing pup joints are shorter segments of casing pipe, typically ranging from a few feet to several feet in length. They are used to adjust the length of the casing string, allowing for precise fitting and alignment of the casing components.

Specifications

- Diameter: Matches the diameter of the casing string, typically ranging from 4.5 inches to 20 inches.

- Length: Varies, commonly available in lengths of 2 feet, 4 feet, 6 feet, 8 feet, 10 feet, and 12 feet.

- Material Grade: Matches the grade of the casing, such as H-40, J-55, N-80, and P-110.

- Thread Types: Includes API round threads, API buttress threads, and premium connections.

Functions

- Length Adjustment: Allows for precise adjustment of the casing string length to ensure proper placement of downhole equipment.

- Connection: Provides a means to connect the casing to other downhole components.

- Flexibility: Offers flexibility in the design and installation of the casing string.

Applications

- Depth Adjustment: Used to adjust the total depth of the casing string to ensure it reaches the desired depth in the wellbore.

- Equipment Placement: Ensures the correct placement of casing collars, landing nipples, and other downhole tools.

- Wellhead Adjustment: Helps in aligning the casing string with the wellhead equipment.

Types of Casing Pup Joints

Standard Pup Joints

Standard pup joints are typically used for general length adjustments in the casing string. They are manufactured to standard lengths and specifications.

Custom Pup Joints

Custom pup joints are made to specific lengths and specifications as required for particular well conditions or operator preferences. These are often used when standard lengths do not meet the precise requirements of the well design.

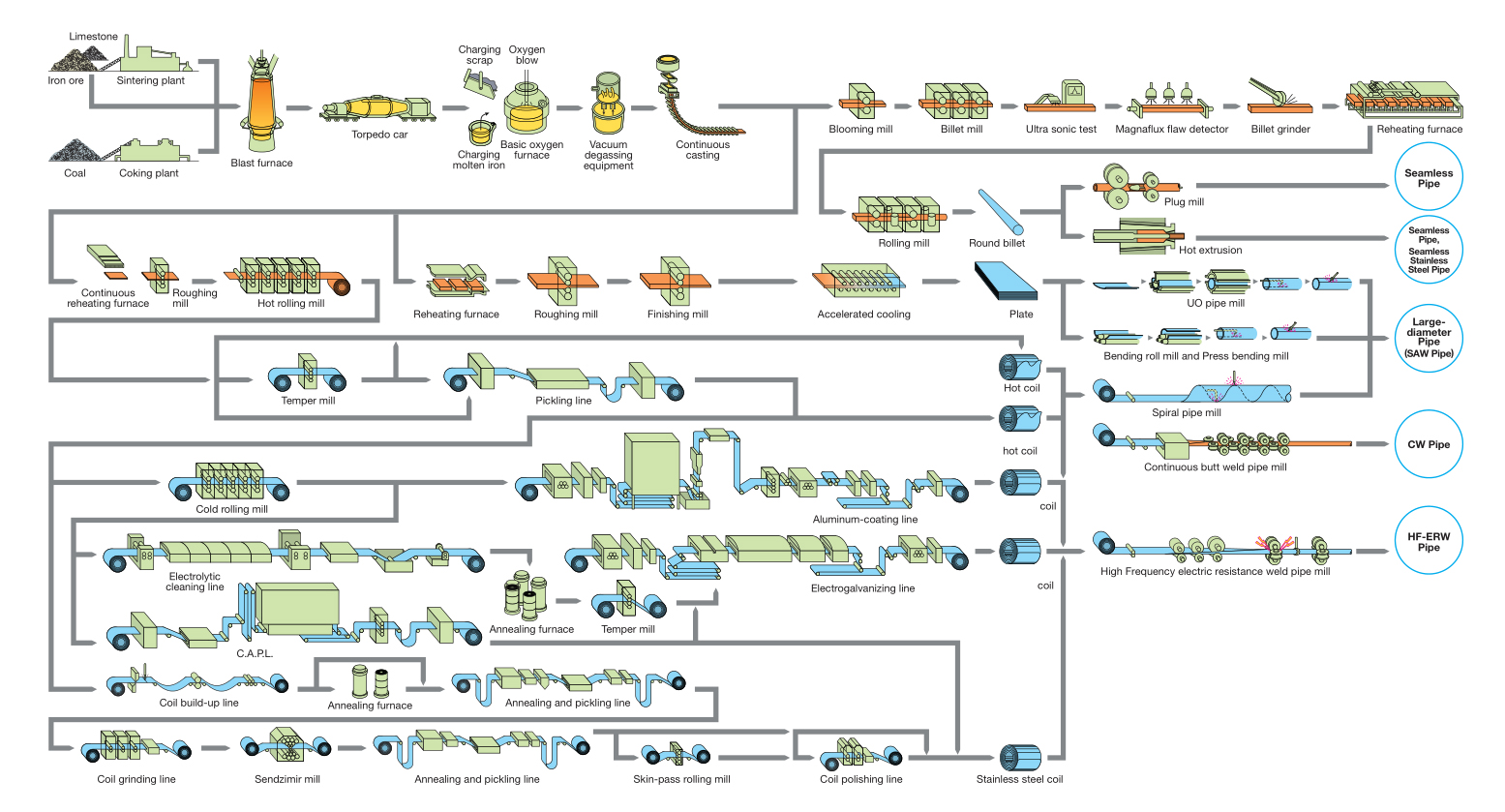

Manufacturing Process

- Material Selection: High-quality steel is selected based on the required specifications and performance criteria.

- Cutting: Steel pipes are cut to the desired length.

- Threading: Threads are machined at both ends of the pup joint to match the casing string connections.

- Inspection: Includes non-destructive testing (NDT) such as ultrasonic testing, magnetic particle inspection, and dimensional verification to ensure quality and performance.

- Heat Treatment: Enhances the mechanical properties of the pup joint, such as strength and toughness.

Example Specifications

A typical casing pup joint might have the following specifications:

- Diameter: 9.625 inches

- Length: 4 feet

- Grade: N-80

- Thread Type: API Buttress Thread

-

Specification

-

Tubing Pup Joint Specifications Outside Diameter 1.05 ~ 4-1/2 in (26.67 ~ 114.3 mm) nominal size OD Weight Standard or Heavy Wall Length 2, 3, 4, 5, 6, 8, 10, 12 ft (with other lengths available upon request) Grade H40, J55, L80, N80/Q, C90, T95, P110 Connection EUE, NUE Standard API 5CT, API 5B Casing Pup Joint Specifications Outside Diameter 4-1/2 ~ 20 in (114.3 ~ 508 mm) nominal size OD Weight Standard or Heavy Wall Length 2, 3, 4, 5, 6, 8, 10, 12, 14, 16, 18, 20 ft (with other lengths available upon request) Grade H40, J55, K55, L80, N80/Q, C90, T95, P110, Q125 Connection BTC, STC, LTC Standard API 5CT, API 5B Parameters

Product: Pup Joint, OCTG Pup Point Application: Pipe Cut into different length used for connect 2 joints of tubing or casing Size: Tubing Coupling : 2-3/8” – 4-1/2” Casing Couping : 4-1/2” – 20′ Length: 2, 3, 4, 6, 8, 10, 12 ft Pipe Standard: API 5CT and 5B J55,K55,N80-1,N80-Q,P110, C95 Surface: Coating Thread: BTC, LTC, STC Special Service Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156 Packing: By carton, wooden case, wooden pallet or requirement of customer Diameters: .75″ through 4.5″ nominal O.D. Weights: Standard or Heavy Wall Lengths: 2, 3, 4, 6, 8, 10, 12 ft. Standard (Lengths up to 20′ available upon request) Grades: J-55, N-80, N-80 Q & T, L-80, P-110, 13-CR and other premium grades Connections: EUE, NUE, Buttress SPECIFICATIONS TUBING PUP JOINT OD GRADE END TYPE LENGTH(FT) 2 3/8″ J/K/L/N/P NUE/EUE 2/3/4/5/6/8/10/12 2 7/8″ J/K/L/N/P NUE/EUE 2/3/4/5/6/8/10/12 3 1/2″ J/K/L/N/P NUE/EUE 2/3/4/5/6/8/10/12 4 1/2″ J/K/L/N/P NUE/EUE 2/3/4/5/6/8/10/12 CASING PUP JOINT OD GRADE END TYPE 4 1/2″ J/K/L/N/P LTC/STC/BTC 5″ J/K/L/N/P LTC/STC/BTC 5 1/2″ J/K/L/N/P LTC/STC/BTC 6 5/8″ J/K/L/N/P LTC/STC/BTC 7″ J/K/L/N/P LTC/STC/BTC 7 5/8″ J/K/L/N/P LTC/STC/BTC 7 3/4″ J/K/L/N/P LTC/STC/BTC 8 5/8″ J/K/L/N/P LTC/STC/BTC 9 5/8″ J/K/L/N/P LTC/STC/BTC 10 3/4″ J/K/L/N/P STC/BTC 11 3/4″ J/K/L/N/P STC/BTC 13 3/8″ J/K/L/N/P STC/BTC

Production process