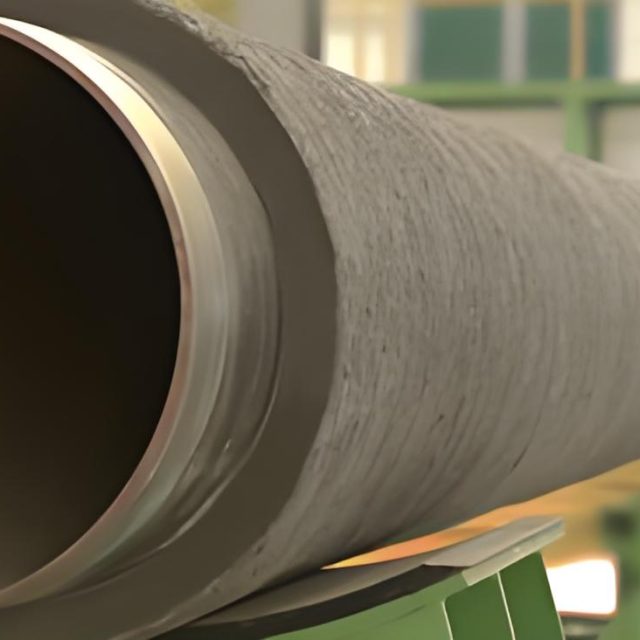

Concrete Weight Coated Pipe CWC

Concrete Coated Pipe Overview

Concrete coated pipes, also known as concrete weight coated (CWC) pipes, are steel pipes coated with a layer of heavy concrete. This type of coating is primarily used to provide negative buoyancy, ensuring that the pipes remain submerged in underwater environments. Additionally, the concrete coating offers mechanical protection against external damage. These pipes are commonly used in subsea and offshore pipeline projects.

Key Features of Concrete Coated Pipe

- Negative Buoyancy:

- The heavy concrete coating adds weight to the pipe, ensuring it stays submerged and stable on the seabed, preventing buoyancy-related issues.

- Mechanical Protection:

- The concrete layer provides robust protection against physical damage from external forces such as anchors, fishing activities, and seabed movements.

- Corrosion Resistance:

- While the primary steel pipe is often coated with anti-corrosion layers (e.g., FBE, 3LPE, 3LPP), the concrete layer further shields the pipe from corrosive marine environments.

- Thermal Insulation:

- The concrete coating can also offer some degree of thermal insulation, maintaining the temperature of the contents within the pipe.

Concrete Weight Coated Pipe Types and Dimensions

Concrete weight coated pipes come in various types and dimensions to meet specific project requirements:

- Types:

- Standard CWC: Standard concrete weight coating applied to steel pipes.

- Reinforced CWC: Concrete coating reinforced with steel mesh or wire for added strength and durability.

- Lightweight CWC: Uses lighter aggregate materials to reduce overall weight while still providing necessary buoyancy control.

- Dimensions:

- Pipe Diameter: Typically ranges from 4 inches to 48 inches or larger, depending on the application.

- Concrete Thickness: Generally ranges from 40 mm to 150 mm, tailored to meet specific buoyancy and protection requirements.

Dimensions Ranges for Concrete Weight Coating Pipe

- Mother pipe standards: API 5L Grade B to Grade 80. ISO 3183 Grade L245 to L555.

Diameter range: 6” to 60”

Pipe Thickness: SCH 20, SCH 40, SCH 80

Length: Up to 12 meters

Concrete Weight Coated Pipe Density

- Concrete formulation can be tailored to any specified density specifications, normally 140, 165 and 190 pounds per cubic foot, smaller or grater densities are also applicable.

Density range: 1800-3450 kg/m3 (112-215 lbs/ft3)

Concrete compressive strength: From 3000 psi to 7200 psi. Up to 50 Mpa.

Concrete thickness: 1 inch to 8 inch. (25 mm to 200 mm)

Common Density: 3040 KG/m3

Concrete Weight Coated Pipe Referred Standards

DNV-OS-F101: Submarine Pipeline Systems – SAWL 245, SAWL 290, SAWL 320, SAWL 360, SAWL 415, SAWL 450, SAWL 485, SAWL 555

ISO 21809-5:2010: Petroleum and natural gas industries – External coatings for buried or submerged pipelines used in pipeline transportation systems – Part 5: External concrete coatings.

• ASTM C42 Standard Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete

• ASTM C87 Test Methods for Effect of Impurities in Fine Aggregate on Strength of Mortar BS 1881 Methods of Testing Concrete

• ASTM C642 Standard Test Method for Specific Gravity, Absorption and Voids in Hardened Concrete

• BS 3148 Test Methods for Water for Making Concrete

• BS 4449 Material Specification for Carbon Steel Bars for Concrete Reinforcement

• BS 4482 Hard Drawn Mild Steel Wire for the Reinforcement of Concrete

• BS 4483 Specification for Steel Fabric for the Reinforcement of Concrete

• ISO 4012 Test Specimen of Determination of Compressive Strength

Product Properties of Concrete Weight Coated Pipe

- Density:

- The density of the concrete used for coating typically ranges from 2,400 to 3,200 kg/m³, depending on the required weight for achieving negative buoyancy.

- Thickness:

- The thickness of the concrete layer varies based on project specifications but generally ranges from 40 mm to 150 mm or more.

- Compressive Strength:

- Concrete coatings exhibit high compressive strength, often exceeding 40 MPa, ensuring durability and resistance to mechanical impacts.

- Adhesion:

- The concrete adheres well to the steel pipe, often facilitated by a mesh or wire reinforcement embedded within the concrete for added stability.

Advantages of Using Concrete Weight Coated Pipe

- Stability in Marine Environments:

- The added weight from the concrete ensures the pipeline remains stable on the seabed, preventing displacement due to currents and waves.

- Enhanced Protection:

- Provides robust mechanical protection against external damage, extending the service life of the pipeline.

- Cost-Effective:

- Reduces the need for additional anchoring systems and maintenance, leading to overall cost savings.

- Versatility:

- Suitable for various subsea applications, including oil and gas transportation, water supply, and sewage disposal.

Minimum Layer Thickness of Concrete Weight Coated Pipe Pipe

- The minimum layer thickness of the concrete coating typically starts at around 40 mm but can be customized based on specific project requirements and environmental conditions.

The Service Life of Concrete Weight Coated Pipe

- Concrete coated pipes are designed for long-term use, often exceeding 30 years, depending on installation conditions, maintenance practices, and environmental factors. Regular inspections and proper maintenance can further extend the service life.

What is Concrete Coating?

Concrete coating involves applying a layer of heavy concrete to the exterior of steel pipes. This is achieved through a process of wrapping the pipe with a mesh or wire reinforcement, followed by the application of concrete, which is then cured to achieve the desired strength and density. The coating process ensures that the concrete adheres firmly to the pipe, providing the necessary weight and protection.

History of the Development of Concrete Coating

- Early Uses:

- Concrete has been used for centuries in construction due to its durability and strength. The concept of using concrete as a protective and weighting material for pipelines emerged with the development of offshore oil and gas exploration.

- Development in the Mid-20th Century:

- The first concrete coated pipelines were developed and installed in the mid-20th century, driven by the need for stable and protected subsea pipelines.

- Advancements in Materials and Techniques:

- Over the years, advancements in concrete technology, including additives and reinforcement techniques, have improved the performance and durability of concrete coatings.

- Modern Applications:

- Today, concrete coated pipes are a standard solution for subsea pipelines, widely used in various marine and offshore projects to ensure stability and protection.

Conclusion

Concrete coated pipes provide a reliable and effective solution for underwater pipeline projects, addressing the challenges of buoyancy, mechanical protection, and durability. By offering enhanced stability and robust protection, these pipes ensure the long-term integrity and functionality of critical subsea infrastructure. The development and continuous improvement of concrete coating techniques have made them an indispensable part of modern pipeline construction in marine environments.