Drill pipe | API 5DP & Heavy Weight type Drill

Drill Pipe Product Specifications

Product Types

- Drill Pipe

- API 5DP Drill Pipe

- Heavy Weight Drill Pipe (HWDP)

- Down Hole Drill Rod

- Square and Hexagonal Kelly

Sizes

- Outer Diameter (OD): 60.32 mm – 168.28 mm

- Wall Thickness (WT): 6.45 mm – 12.7 mm

- Length: R1, R2, R3

Pipe Standards

- API 5DP Grades: E75, X95, G105, S135

Upset Styles

- IU (Internal Upset)

- EU (External Upset)

- IEU (Internal-External Upset)

Tool Joint Wear-resistant Belts

- TK34

- TC2000

- Arnco 100XT

- Arnco 200XT

- Arnco 300XT

- Arnco 400XT

Internal Coatings for Drill Pipe

- TK34

- DPC

- TC2000

- TC3000

Connection Types

- NC Series: NC26, NC31, NC38, NC40, NC46, NC50

- Full Hole (FH): 5 1/2 FH, 6 5/8 FH

Applications

- Mine Blasting

- Water Well Drilling

- Geothermal Wells Drilling

- Fore Poling

- Coal and Nonferrous Metal Mining Projects

Product Overview

Drill Pipe

Drill pipes are heavy, seamless pipes that provide rotation for circulating drilling fluid. They pump the drilling fluid back up the annulus, which is the space between the casing and the piping or tubing surrounding it, facilitating fluid circulation in the well. Drill pipes must withstand high axial tension and torque, making strength and durability critical.

Heavy Weight Drill Pipe (HWDP)

Heavy weight drill pipes are used in various drilling applications to provide additional weight and stability to the drill string. They are available in multiple configurations, including standard, tri-spiral, and spiral-wate designs.

Heavy Weight Drill Pipe Sizes

- Outer Diameter (OD): 2 3/8″ to 6 5/8″

- Length: Range 2 and Range 3

Grades and Connection Threads

- Grades: E75, X95, G105, S135

- Connection Threads: NC26, NC31, NC38, NC40, NC46, NC50, 5 1/2 FH, 6 5/8 FH

Upset Styles

- Internal Upset (IU)

- External Upset (EU)

- Internal-External Upset (IEU)

Drill Stem Accessories

- Drill Pipe Pup Joint

- Sub

- Square Kelly: 2 1/2″ – 6″

- Hexagonal Kelly: 3″ – 6″

- Kelly (Square Kelly / Hexagonal Kelly)

Additional Products

- High Strength Drill Pipe

- Thick Wall Drill Pipe

- Sour Service Drill Pipe

- Horizontal Directional Drill Pipe

-

Specification

-

outer diameter

normal weight

steel grade

wall thickness

upset ends

tool joint designation

in mm in mm 2 3/8 60.32 6.65 E,X,G 0.280 7.11 EU NC26 2 7/8 73.02 10.40 E,X,G,S 0.362 9.19 EU NC31 3 1/2 88.90 9.50 E 0.254 6.45 EU NC38 13.30 E,X,G,S 0.368 9.35 EU NC38 13.50 E,X,G 0.449 11.40 EU NC38 S 0.449 11.40 EU NC40 4 101.60 14.00 E,X,G,S 0.330 8.38 IU NC40 E,X,G,S 0.330 8.38 EU NC46 4 1/2 114.30 13.75 E 0.271 6.88 IU NC46 13.75 E 0.271 6.88 EU NC46 16.60 E,X,G,S 0.337 8..56 EU NC50 20.00 E,X,G,S 0.430 10.92 EU NC50 16.60 E,X,G,S 0.337 8.56 IEU NC46 20.00 E,X,G,S 0.430 10.92 IEU NC46 5 127.00 19.50 E,X,G,S 0.362 9.19 IEU NC50 19.50 E,X,G,S 0.362 9.19 IEU 5 1/2 FH 25.60 E,X,G 0.500 12.70 IEU NC50 25.60 E,X,G,S 0.500 12.70 IEU 5 1/2 FH 5 1/2 139.70 21.90 E,X,G,S 0.361 9.17 IEU 5 1/2 FH 24.70 E,X,G,S 0.415 10.54 IEU 5 1/2 FH 6 5/8 168.28 25.20 E,X,G,S 0.330 8.38 IEU 6 5/8 FH 27.70 E,X,G,S 0.362 9.19 IEU 6 5/8 FH Note: EU— external upset; IU— internal upset; IEU—internal & external upset.

Dimension Tolerances

Tolerance Drill-pipe-body Outside Diameter

Pipe body D≤101.60mm,±0.79mm D≥114.30mm,+1.0%, -0.5%D Drill-pipe-body behind the Meu

D≥60.32~≤88.90mm,+2.38%, -0.79%D D>88.90~≤127.00mm,+2.78mm, -0.75%D D>127.00~≤168.28mm,+3.18mm,-0.75%D Wall Thickness 0, -12.5%t Chemical Composition, Mass Fraction(%)

steel grade

P (%) S (%) ≤ ≤ Pipe body

E 0.030 0.020 X, G, S 0.020 0.015 Tool Joint 0.020 0.015 Mechanical Properties

steel grade

tensile properties (21℃±3℃) Charpy V-notch longitudinal absorbed-energy (21℃±3℃)

yield strength (Mpa)

tensile strength

(Mpa)

elongation(%)

10*10 average(min)

10*7.5 average(min)

10*5 average(min)

min max min E 517 724 689 54(47) 43(38) 30(26) X 655 862 724 G 724 931 793 S 931 1138 1000 Remarks: k—constant, equal to 1944 (62500); A—cross-sectional area of tensile specimen, mm2(in2); Udp—specified minimum tensile strength, MPa(Ib/in2)

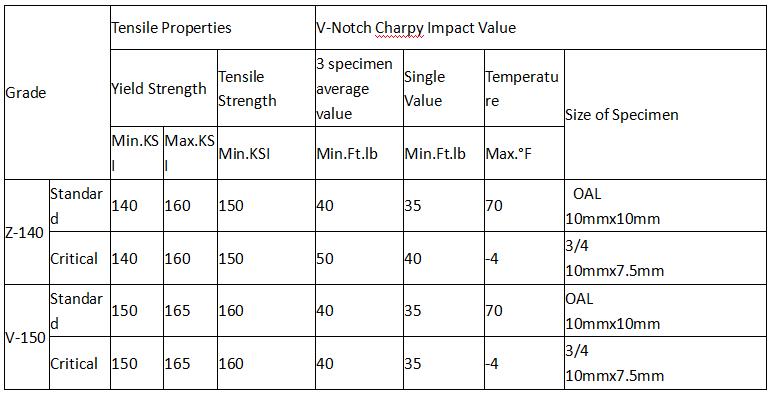

High Strength Drill Pipe

Besides the common 2″-10″ API drill pipe, CSC also manufacture high strength drill pipe, like Z-140 and V-150, the performances as below,

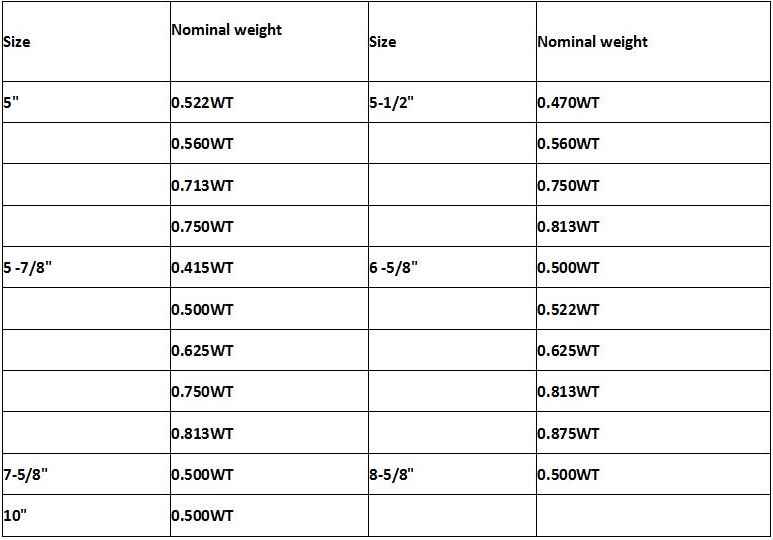

Thick Wall Drill Pipe

the thick-wall drill pipe like below

Sour Service Drill Pipe

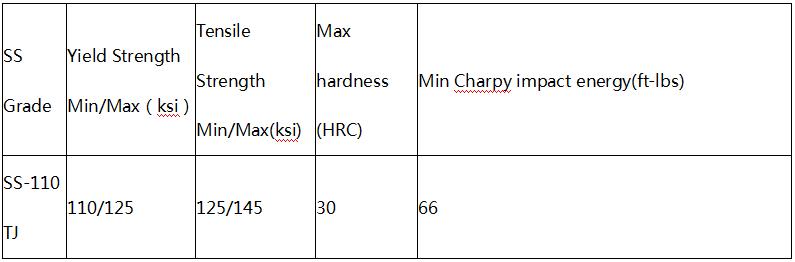

SS Drill Pipe Body Mechanical Performance

SS drill pipe tool joint mechanical performance

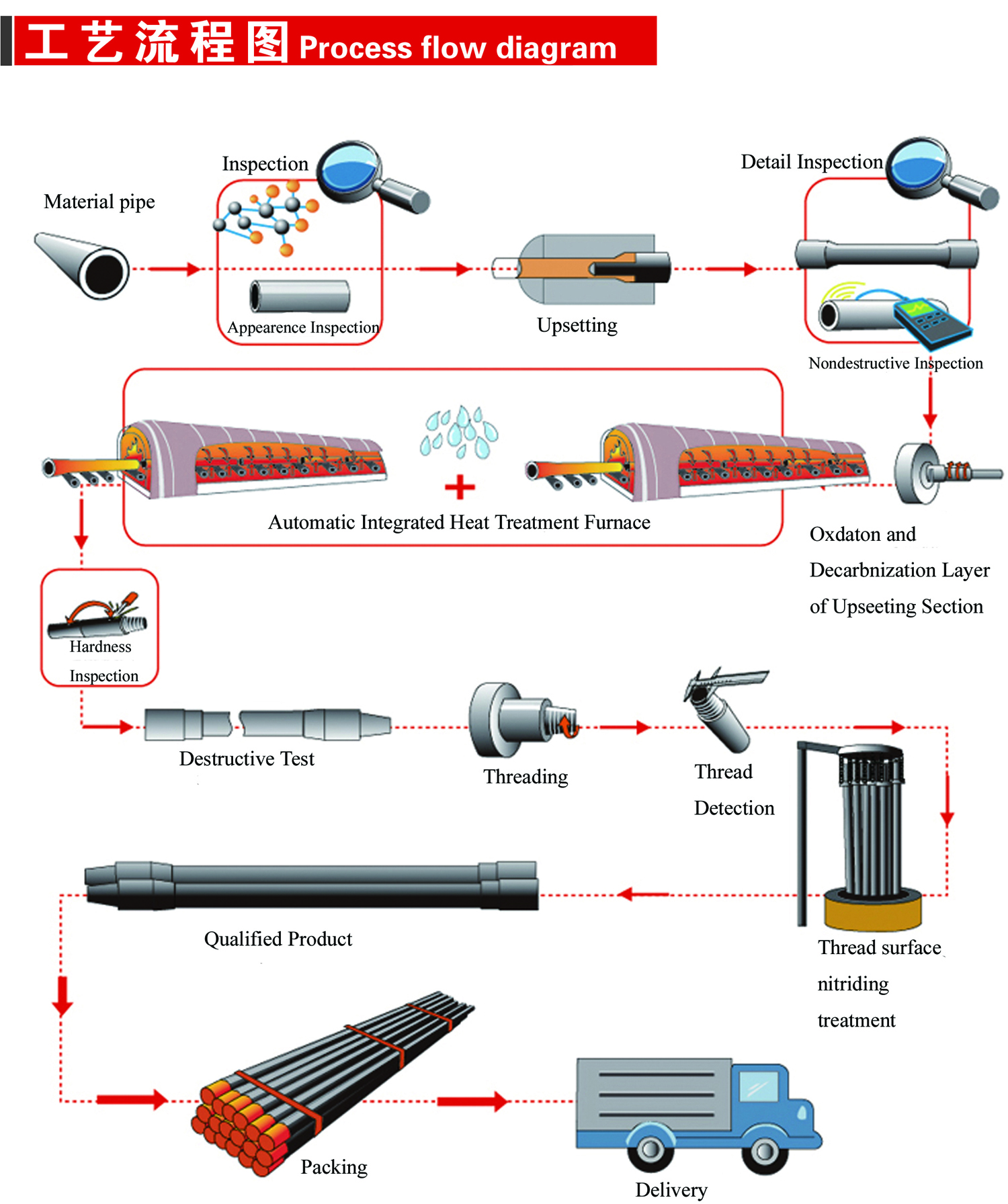

Production process

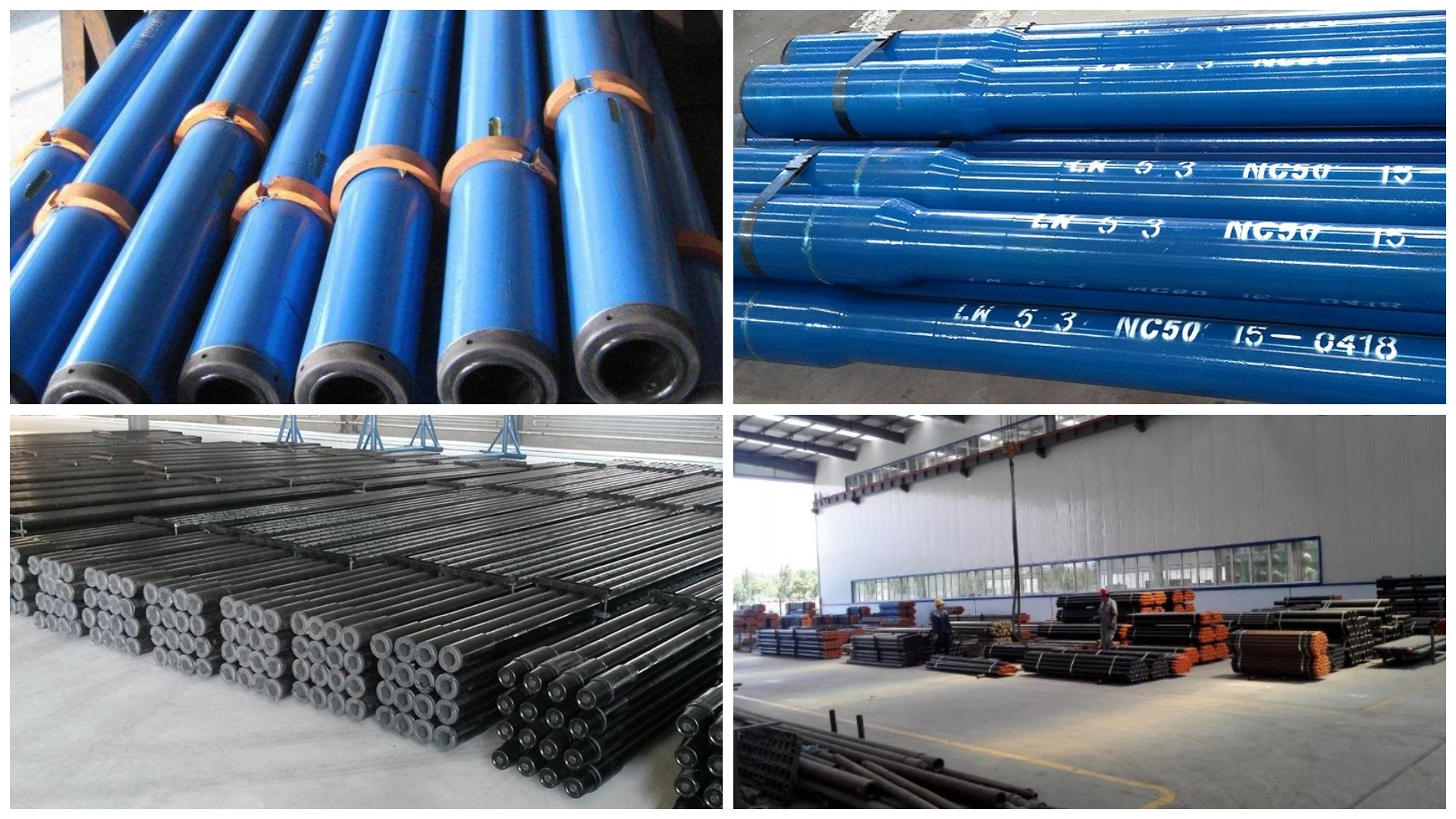

Packaging

High Strength Drill Pipe

High strength drill pipes are designed to withstand the demanding conditions of deep well drilling. These pipes offer enhanced mechanical properties to cope with high tensile loads and extreme drilling environments.

Thick Wall Drill Pipe

Thick wall drill pipes provide increased durability and resistance to wear and fatigue, suitable for operations where higher strength and longer service life are required.

Sour Service Drill Pipe

Sour service drill pipes are engineered to resist the corrosive effects of hydrogen sulfide (H2S) in sour gas applications. These pipes meet stringent requirements for materials and coatings to ensure safety and longevity.

Horizontal Directional Drill Pipe

Horizontal directional drill pipes are specifically designed for horizontal drilling applications. They offer superior flexibility and strength to cope with the unique challenges of horizontal drilling operations.

Heavy Weight Drill Pipe (HWDP)

Heavy weight drill pipes add weight to the drill string without increasing its diameter, improving the performance and stability of the drill string. They are available in several configurations:

- Standard HWDP

- Tri-spiral HWDP

- Spiral-Wate HWDP

- High Strength Welded HWDP

Drill Stem Accessories

Drill stem accessories are essential components that facilitate the connection and operation of the drill string. Our range includes:

- Drill Pipe Pup Joint: Short sections of drill pipe used to adjust the length of the drill string.

- Sub: Used to connect different sizes or types of drill pipe or other components.

- Kelly (Square Kelly / Hexagonal Kelly): The kelly is a key component in the drilling rig’s rotary system, providing the drive to turn the drill string.

Kelly Sizes

- Square Kelly: 2 1/2″ – 6″

- Hexagonal Kelly: 3″ – 6″