DSAW Pipe

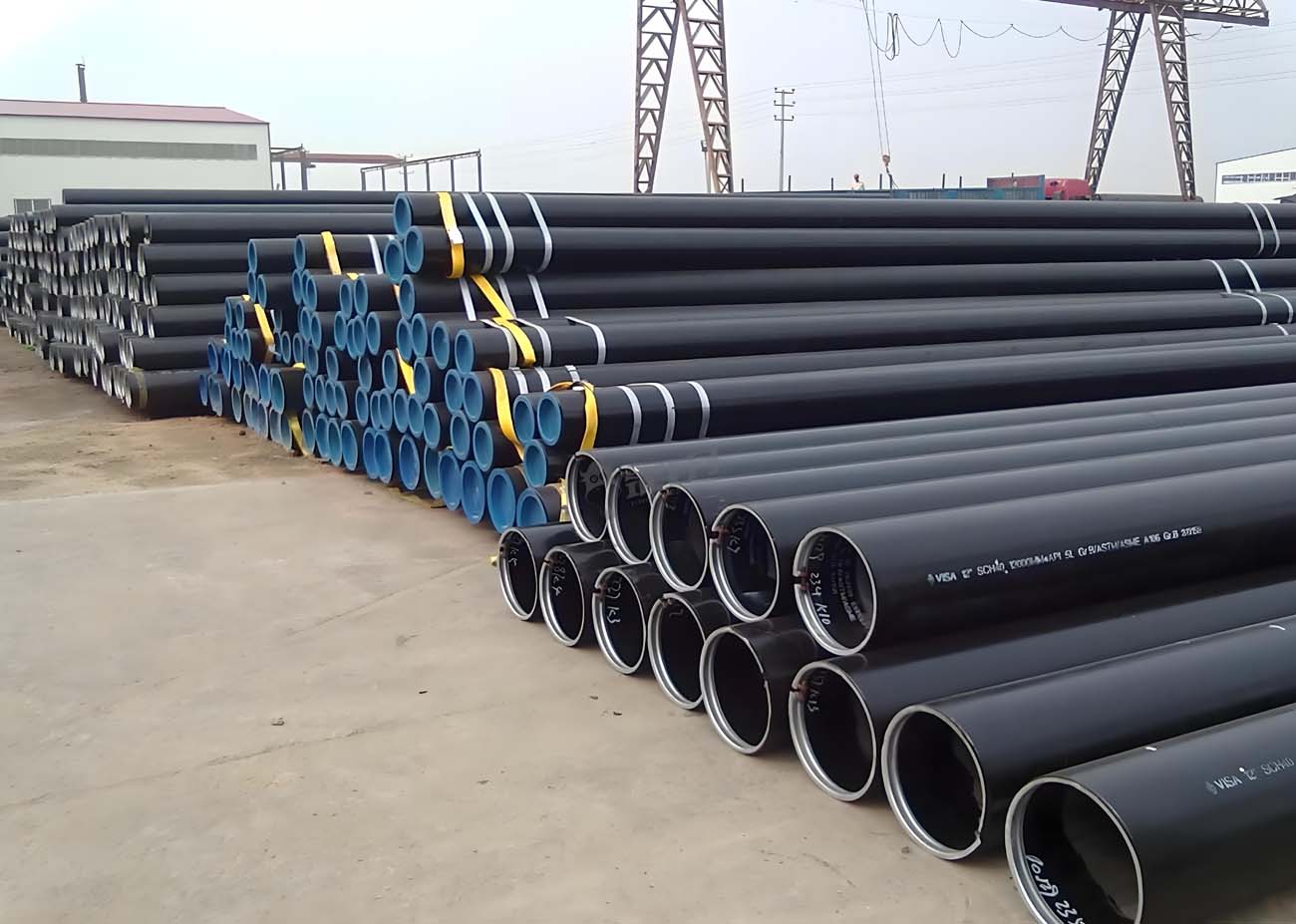

DSAW Pipe Overview

Double Submerged Arc Welded (DSAW) steel pipes are renowned for their robust construction and versatility. Available in both straight and spiral welded formats, these pipes are utilized across various industries, such as oil and gas, petrochemical, and construction. DSAW pipes can be manufactured to precise inside or outside dimensions and in large diameters, making them suitable for high-capacity applications.

Types of DSAW Pipes

- Straight Welded DSAW Pipes: Characterized by a longitudinal weld seam.

- Spiral Welded DSAW Pipes: Feature a spiral seam that runs the length of the pipe, allowing for longer pipe sections, up to 155 feet.

Manufacturing Process

Straight DSAW Pipes

- Forming: Steel plates are formed into cylindrical shapes.

- Edge Preparation: Edges are beveled to create V-shaped grooves.

- Welding:

- Internal Welding: A single pass of an arc welder on the interior.

- External Welding: A single pass of an arc welder on the exterior. The welding arc is submerged under flux, ensuring 100% penetration for a strong bond.

Spiral DSAW Pipes

The production process for spiral DSAW pipes involves the following steps:

- Raw Materials: Strip steel coils, welding wires, and fluxes undergo strict physical and chemical testing before use.

- Butt Joint Welding: The strip steel head and tail are butt-welded using single or double wire submerged arc welding. After coiling into a steel pipe, automatic submerged arc welding is used for repair welding.

- Pre-Forming Treatments: The strip undergoes leveling, edge trimming, edge planing, surface cleaning, and pre-bending.

- Pressure Control: An electric contact pressure gauge controls the pressure on the conveyor cylinders to ensure smooth strip conveying.

- Roll Forming: External or internal control roll forming is used.

- Weld Gap Control: A device ensures the weld gap meets welding requirements, strictly controlling the pipe diameter, misalignment, and weld gap.

- Welding: Internal and external welding is performed using American Lincoln electric welding machines for single or double wire submerged arc welding, ensuring stable welding specifications.

- Ultrasonic Inspection: Weld seams are inspected by an online continuous ultrasonic automatic flaw detection instrument, ensuring 100% non-destructive testing coverage. Defects trigger an automatic alarm and marking for process parameter adjustments.

- Cutting: An air plasma cutting machine cuts the steel pipe into individual pieces.

- First Inspection: The first three steel pipes of each batch undergo a strict first inspection system to check mechanical properties, chemical composition, weld fusion status, surface quality, and non-destructive inspections.

- Defect Re-Examination: Weld areas with continuous flaw detection marks are re-checked by manual ultrasonic and X-ray inspection. Defects are repaired and re-inspected until confirmed.

- X-ray Inspection: Pipes with strip butt welds and D-shaped joints intersecting spiral welds are inspected by X-ray television or filming.

- Hydrostatic Pressure Test: Each steel pipe undergoes a hydrostatic pressure test with radial seal pressure. Test parameters are controlled and recorded by a steel pipe hydraulic microcomputer detection device.

- End Processing: Pipe ends are mechanically processed to accurately control verticality, bevel angle, and obtuse edge of the end face.

Advantages of DSAW Pipes

- High Strength: Suitable for high-pressure applications.

- Consistent Weld Quality: Double welding ensures a defect-free weld.

- Large Diameter Production: Capable of producing pipes with large diameters for high-capacity needs.

- Uniform Wall Thickness: Ensures structural integrity and durability.

- Versatility: Applicable in various industries including oil and gas, water supply, structural projects, and more.

DSAW Pipe Applications

- Oil Industry

- Gas Industry

- Filtration Industry

- Refrigeration Industry

- Refining Industry

- Petrochemical Industry

- Offshore Industry

Welding Advantages

- Automation: Fully automated process ensures consistency.

- Submerged Arc Welding: Provides strong heat exchange and protection, resulting in high-quality welds.

- High Efficiency: High current use under the flux allows for efficient welding, suitable for large-scale projects such as the West-East Gas Pipeline.

Technical Capabilities

Our technical team can assist in developing comprehensive pipeline projects, offering integrated solutions from basic DSAW pipe production to complete package quotations, including ID/OD coating, double jointing, and transportation.