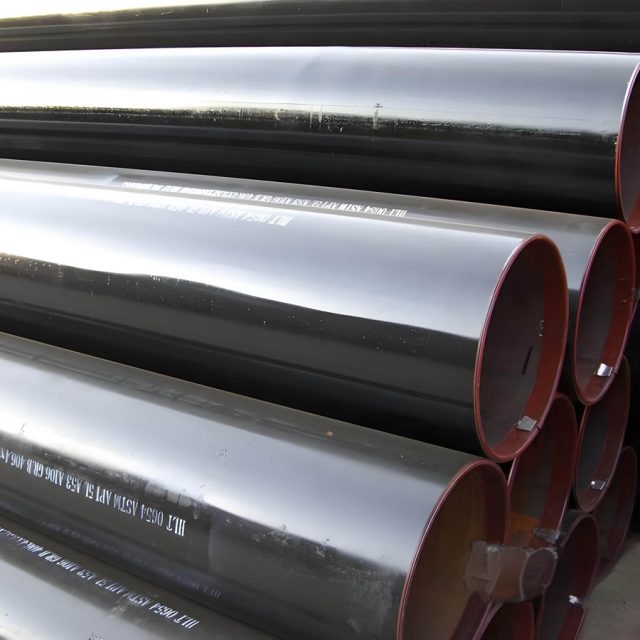

EFW Steel Pipe

EFW (Electric Fusion Welded) steel pipes are a type of pipe manufactured using electric fusion welding, a process that involves the fusion of materials using an electric arc. This welding method is typically used for producing large-diameter pipes and is known for its robust welds and high-quality finish. Below is a detailed overview of EFW steel pipes:

Manufacturing Process

The EFW process involves the following steps:

- Preparation of Plate or Coil: The steel plate or coil is first prepared, ensuring it meets the required specifications for thickness, width, and chemical composition.

- Forming: The prepared plate or coil is formed into a cylindrical shape, typically using a roll forming or UO (U-ing and O-ing) process.

- Electric Fusion Welding: The edges of the formed cylinder are brought together, and an electric arc is used to melt and fuse the edges, creating a strong weld. This process can be done using either a single-pass or multi-pass welding technique, depending on the pipe’s thickness.

- Inspection and Testing: Post-welding, the pipe undergoes rigorous inspection and testing, including non-destructive testing (NDT) methods such as ultrasonic testing (UT) and radiographic testing (RT) to ensure the integrity of the weld and the overall quality of the pipe.

- Finishing: The pipe is then finished by removing any excess weld material, calibrating the dimensions, and applying coatings or other protective measures as needed.

Key Features

- Welding Method: Utilizes electric arc fusion to create strong and reliable welds.

- Diameter: Suitable for large-diameter pipes, typically ranging from 16 inches (406 mm) to 100 inches (2540 mm) or more.

- Thickness: Capable of welding thicker walls than some other welding methods, making it ideal for high-pressure applications.

- Quality: Produces high-quality welds with excellent mechanical properties and structural integrity.

Sizes for EFW (Electric Fusion Welded) Pipe:

- Available in sizes from 1/8” through to 64” Nominal Bore.

Material Grades for EFW Electric Fusion Welded Pipe:

- Carbon Steel: A106 Gr.B, A106 Gr.C, API 5L B

- Stainless Steel: A312 304/L, 310, 316/L, 321/H, 347/H, 410, 440, 904L

- Low Temperature: ASTM A333 Gr.6/3

- Alloy Steel: A335 P1, P5, P9, P11, P12, P22, P91

- High Yield: API 5L X42, X52, X60, X65, X70

- 6% Moly / Duplex & Super Duplex: UNS S31254, UNS S31803, S32205, UNS S32760, S32750, S32507

- Nickel Alloys: 200, 400, K500, 600, 625, 800, 825

- Alloys: ALLOY 20, ALLOY C, ALLOY C276, ALLOY B2

- Aluminium: 5083, 5154, 5251, 6061, 6063, 6082

- Unusual Grades: Bronze, Brass, Copper, Cupro Nickel, Titanium

Applications

EFW steel pipes are commonly used in industries and applications where large-diameter and high-strength pipes are required:

- Oil and Gas Industry: Used for transporting crude oil, natural gas, and refined products.

- Petrochemical Industry: Suitable for pipelines carrying chemicals and petrochemical products.

- Water Supply Systems: Utilized in large-scale water distribution and transmission systems.

- Structural Applications: Employed in the construction of infrastructure such as bridges, buildings, and offshore platforms.

- Power Generation: Used in power plants for steam and coolant piping systems.

Advantages

- High Strength: The electric fusion welding process produces robust welds, making EFW pipes suitable for high-pressure and high-stress applications.

- Large Diameter Capability: Ideal for applications requiring large-diameter pipes, which are often challenging to produce using other methods.

- Consistency and Reliability: EFW pipes offer consistent quality and reliability, ensuring long-term performance in demanding environments.

- Versatility: Can be manufactured to meet a wide range of standards and specifications, making them versatile for various industrial applications.

Comparison with Other Welded Pipes

| Feature/Aspect | EFW Pipes | ERW Pipes | HFW Pipes |

|---|---|---|---|

| Welding Method | Electric arc fusion | Low-frequency or high-frequency current | High-frequency current |

| Diameter Range | Large (16 inches to over 100 inches) | Small to medium | Medium |

| Wall Thickness | Suitable for thicker walls | Typically thinner | Medium to thick |

| Strength | High | Adequate for most applications | Higher than ERW, suitable for high-stress |

| Application Examples | Oil & gas, petrochemical, water supply | Water, gas conveyance, structural, automotive | Oil & gas, high-pressure, structural |

| Cost | Generally higher due to the complex process | More cost-effective | Slightly higher due to superior quality |

EFW Steel Pipe VS ERW steel pipe

Both EFW (Electric Fusion Welded) and ERW (Electric Resistance Welded) steel pipes are commonly used in various industries for transporting fluids and gases. However, they are manufactured using different processes and have distinct characteristics. Here’s a detailed comparison:

EFW (Electric Fusion Welded) Steel Pipe

Manufacturing Process

- Fusion Welding: EFW pipes are produced by heating the edges of the steel and fusing them together using an electric arc or high-frequency induction welding.

- Material: Typically made from high-quality steel plates or coils.

- Heating: The steel edges are heated to their melting point, and pressure is applied to join them, creating a weld.

Characteristics

- Strength and Durability: EFW pipes are known for their high strength and durability, making them suitable for high-pressure applications.

- Thickness: They can be produced with thicker walls, which is beneficial for specific industrial uses.

- Quality: The welding process ensures a high-quality seam, reducing the likelihood of defects.

Applications

- Oil and Gas Industry: Used for transporting oil and gas due to their high strength and ability to withstand high pressures.

- Structural Applications: Used in construction and infrastructure projects requiring robust and durable materials.

- High-Temperature Environments: Suitable for applications involving high temperatures.

ERW (Electric Resistance Welded) Steel Pipe

Manufacturing Process

- Resistance Welding: ERW pipes are made by rolling metal and welding it longitudinally across its length using electric resistance.

- Material: Typically made from steel coils.

- Heating: The edges of the steel strip are heated using electric resistance before being pressed together to form a weld.

Characteristics

- Cost-Effective: The manufacturing process is relatively simpler and more cost-effective compared to EFW pipes.

- Consistency: The process allows for the production of pipes with consistent dimensions and wall thickness.

- Surface Finish: ERW pipes generally have a better surface finish due to the precise control in the manufacturing process.

Applications

- Water Supply Lines: Commonly used in water supply lines due to their good quality and cost-effectiveness.

- Automotive Industry: Used in the manufacturing of automobile components.

- Low to Medium Pressure Applications: Suitable for applications with lower pressure and temperature requirements compared to EFW pipes.

Key Differences

| Feature | EFW (Electric Fusion Welded) | ERW (Electric Resistance Welded) |

|---|---|---|

| Manufacturing Process | Fusion welding using electric arc or induction | Resistance welding using electric resistance |

| Material Source | Steel plates or coils | Steel coils |

| Strength | Higher strength, suitable for high-pressure applications | Moderate strength, suitable for low to medium pressure |

| Cost | Generally more expensive due to complex process | More cost-effective |

| Applications | Oil & gas pipelines, structural applications, high-temperature environments | Water supply lines, automotive components, low to medium pressure applications |

| Wall Thickness | Can be produced with thicker walls | Typically have consistent, thinner walls |

| Surface Finish | May have a rougher finish due to welding process | Generally smoother finish |

Conclusion

Both EFW and ERW steel pipes have their unique advantages and are chosen based on specific application requirements. EFW pipes are preferred for high-pressure and high-temperature applications due to their strength and durability, while ERW pipes are favored for their cost-effectiveness and suitability for low to medium pressure applications with consistent dimensions.