The ERW (Electrical Resistance Welded) steel pipe is also known as straight seam pipe, it is manufactured by using electric resistance welding. The weld lies inside the tube and is therefore non-visible from the outside. The wall thickness of our ERW steel pipe can be customized according to your specific requirement with a thickness deviation no more than 0.2mm. In addition, this pipe can be manufactured in compliance with different standards upon request, including ASTM, API5L, A53 BS1387-85, GB/T3092-2001, etc.

Application

ERW steel pipe is broadly applied in pipeline construction, pipe piling, fabrication, fence, bollards, sign poles, water well drilling, and more.

Carbon Steel ERW Pipe

Outer Diameter Size: 3″-24″

Wall Thickness: 4mm-12.7mm

Specification & Grades: 20#, 16Mn, A53(A,B), J55, Q235, Q195 X42 Grade B

Standard: API 5L, A53, A-519

Stainless ERW Pipe

Outer Diameter Size: 14mm-2200mm

Wall Thickness: 0.5mm-30mm

Standard: ASTM (ASME) SA/A312/M ASTM A358

Material: TP304, TP304L, TP310/S, TP316L, TP316/316L Dual Grade, TP317L, TP321, TP347

Special Treatment

Galvanization, black painting, anti-corrosion, cement lining

Packaging

The ERW steel pipe can be tied into a bundle or packed with wooden cases. Plastic caps are provided to protect the two sharp ends.

Service

Please contact us for any queries and we will try our best to help you through.

Abter is a China based ERW steel pipe manufacturer and supplier. Our main products include boiler steel tube, 3PE anticorrosion steel pipes, fiberglass insulated pipeline, to name a few. All of our high quality products are offered at competitive prices. The full chain of manufacturing foam insulated pipeline, SSAW steel pipe, etc. can be completed in China, even in one city. Lower manufacturing cost saves your purchasing cost. The detailed information of each product is shown in the corresponding product page.

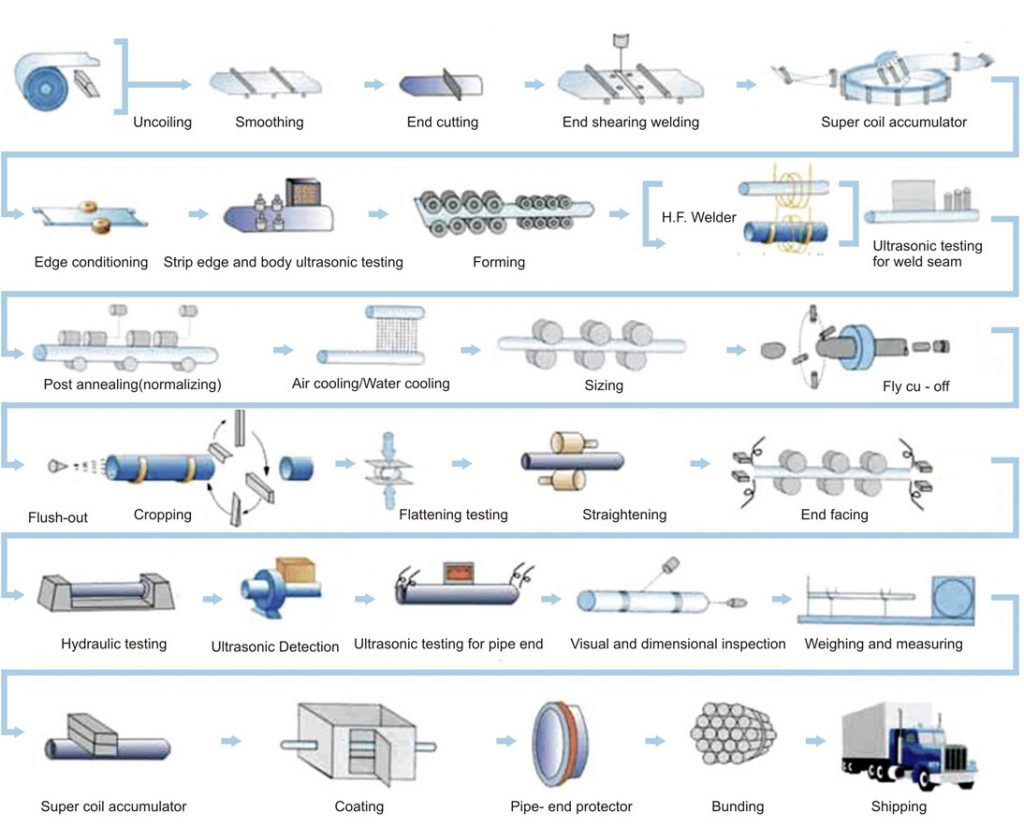

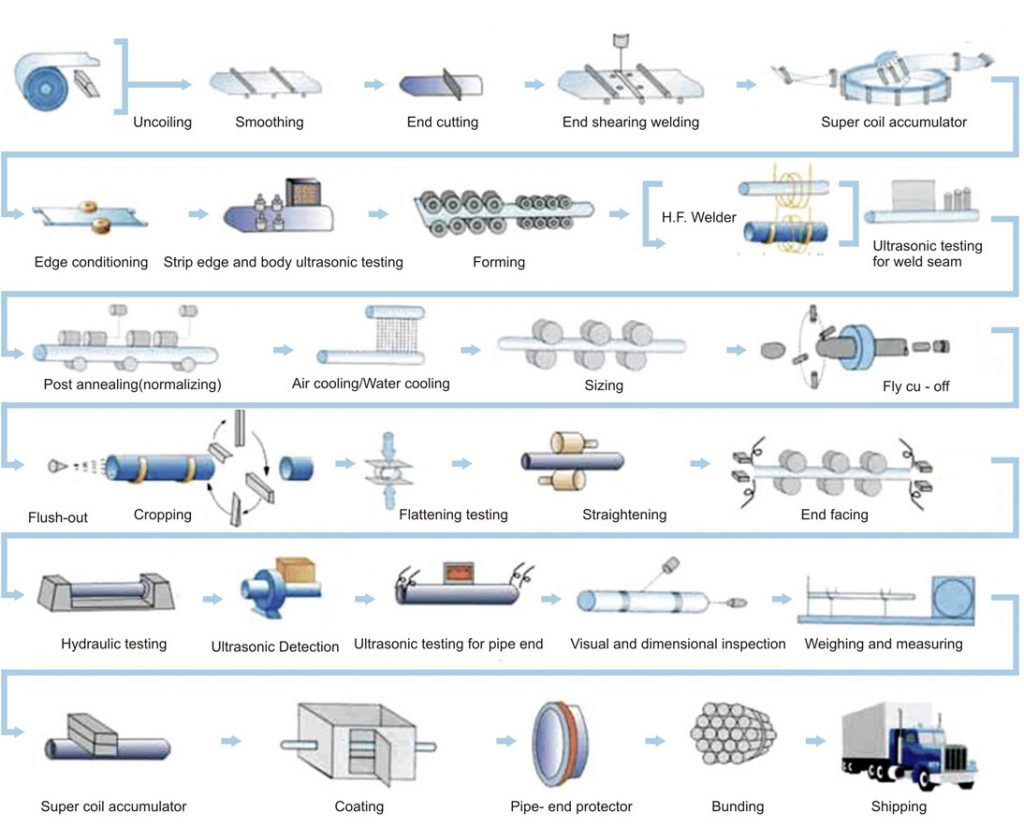

ERW welded pipe manufacturing process

ERW/HFW Longitudinally Welding Steel Line Pipe (Electric Resistance Welding ) Manufacturing Flow Chart

Uncoiling – Flattening – Shearing and Butt Welding – Loop Storing – Plate UT – Trimming – Forming – High Frequency Welding – Removal of Inside and Outside Blurs – Ultrasonic Testing – Annealed by Medium Frequency – Air Cooling – Water Cooling – Sizing – Straightness – Cutting Off – Dimension and Initial Surface Inspection – Pipe Ends Beveling – Hydrostatic Test – Ultrasonic Testing of Entire Tube – Off Line Ultrasonic Testing – Ultrasonic Testing for Pipe Ends – Dimension and Final Surface Inspection – Corrosion Resistant Coating – Marking – Pipe Ends Protection – Inspection and Warehousing

Specification of ERW steel pipe:

The chemical composition of the steel material can be altered according to a number of standards such as API 5L, etc. to meet customers’ specific requirement.

| API 5L/ASTM A53 GR.B (Small Diameter ERW Steel Pipe) |

| Outside Diameter |

Wall Thickness |

Outside Diameter |

Wall Thickness |

| (mm) |

(mm) |

(mm) |

(mm) |

33.4

(1″) |

2.1-2.4 |

Φ133 |

3.0-5.75 |

| 2.5-3.25 |

6.0-7.75 |

| 3.5-4.0 |

8.0-10 |

42.3

(1.2″) |

2.1-2.4 |

Φ139.7

(5″) |

3.0-4.5 |

| 2.5-3.5 |

4.75-5.75 |

| 3.75 |

6.0-7.75 |

| 4.0-5.0 |

8.0-10 |

48.3

(1.5″) |

2.1-2.4 |

Φ152 |

3.0-4.5 |

| 2.5-3.25 |

4.75-5.75 |

| 3.5-3.75 |

6.0-7.75 |

| 4.0-4.25 |

8.0-10.0 |

| 4.5-6.0 |

Φ159 |

3.25-6.75 |

Φ60.3

(2″) |

3.0-4.0 |

6.8-7.75 |

| 4.25-4.75 |

8.0-10.0 |

| 5.0-5.75 |

10.0-11.75 |

| Ф73 |

3.0-4.75 |

Φ165 |

3.0-6.0 |

| 4.8-5.25 |

6.25-7.0 |

| 5.5-7.0 |

/ |

Φ76.1

(2.5″) |

3.0-4.0 |

/ |

| 4.25-4.75 |

Φ168.3 |

3.5-5.75 |

| 5.0-5.25 |

6.0-8 |

| 5.5-7.0 |

8.25-8.75 |

Φ88.9

(3″) |

3.0-4.0 |

9.0-9.75 |

| 4.25-4.75 |

10.0-11.75 |

| 5.0-5.25 |

/ |

| 5.5-6.0 |

Φ177.8

(Φ180) |

3.75-5.75 |

| 8 |

6.0-7.75 |

| Φ108 |

3.0-4.5 |

8.0-8.75 |

| 4.75-5.75 |

9.0-9.75 |

| 6.0-6.25 |

10.0-11.75 |

| 6.5-9.0 |

/ |

Φ114.3

(4”) |

3.0-4.0 |

Φ193.7 |

4.0-6.75 |

| 4.25-4.75 |

6.8-7.75 |

| 5.0-6.0 |

8.0-9.75 |

| 6.25-7.75 |

10.0-11.75 |

| 8.0-10 |

/ |

| Φ127 |

3.0-4.75 |

Φ203 |

3.0-6.75 |

| 5.0-5.75 |

6.8-8.0 |

| / |

8.25-11.75 |

| / |

/ |

|

| API 5L GR.B/ASTM A53 GR.B (HOT EXPANDED ERW STEEL PIPE) |

| Outside Diameter |

Wall Thickness |

Outside Diameter |

Wall Thickness |

| (mm) |

(mm) |

(mm) |

(mm) |

| 245, 273 |

5.0-9.28 |

450, 457, 508, 530 |

6.5-11.98 |

| 9.45-9.98 |

12.0-14.5 |

| 10.0-11.78 |

15.0-17.8 |

| 299 |

5.0-9.28 |

18.0-20.0 |

| 9.45-9.98 |

560, 610, 630 |

6.5-11.98 |

| 10.0-11.78 |

12.0-14.5 |

| 325 |

5.5-9.28 |

15.0-17.8 |

| 9.48-10.48 |

18.0-20.0 |

| 10.58-11.78 |

660 |

7.5-11.98 |

| 351, 355, 377 |

5.5-11.98 |

12.0-14.5 |

| 12.0-15 |

15 |

| 15.5-16 |

720, 820 |

8.5 |

| 402, 406, 426 |

5.5-11.98 |

12.0-14.5 |

| 12.0-14.5 |

15.0-19.98 |

| 15.5-16 |

18.0-20.0 |

|

| API 5L/ASTM A53 GR.B (Hot Rolled ERW Steel Pipe) |

| Outside Diameter |

Wall Thickness |

Outside Diameter |

Wall Thickness |

| (mm) |

(mm) |

(mm) |

(mm) |

| 219、245 |

5.0-11.75 |

462 |

5.75-11.75 |

| 273 |

5.0-11.75 |

12.5-13.75 |

| 12.5-13.75 |

457、478 |

5.75-11.75 |

| 299 |

5.5-11.75 |

12.5-13.75 |

| 12.5-13.75 |

14.5-17.75 |

| 325 |

5.5-11.75 |

508 |

5.75-11.75 |

| 12.5-13.75 |

12.5-13.75 |

| 355 |

5.5-11.75 |

14.5-17.75 |

| 12.5-13.75 |

529/559/610/630 |

5.75-11.75 |

| 377 |

5.75-11.75 |

12.5-13.75 |

| 12.5-13.75 |

14.5-17.75 |

| 406 |

5.75-11.75 |

660 |

7.5-11.75 |

| 12.5-13.75 |

12.5-13.75 |

| / |

14.5-17.75 |

|

Related Posts

ERW welded steel pipes

ERW Steel Pipe(Electric Resistance Welded Pipe), A53 ERW Pipe, ERW Carbon Steel Pipe Product Details of ERW steel pipe Pipe End: square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled, Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE) Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps. Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Hardness Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, NDT TEST ( ET TEST, RT TEST, UT TEST) For ERW Line Pipe For ERW Casing For ERW Structure Tube For High pressure and high temperature

ERW Welded Pipe and Manufacturing Process

ERW Steel Pipe(Electric Resistance Welded Pipe), A53 ERW Pipe, ERW Carbon Steel Pipe Product Details of ERW steel pipe Pipe End: square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled, Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE) Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

ERW Steel Pipe

ERW steel pipes are an essential component in various industrial applications, providing a reliable and economical solution for fluid transportation and structural uses. The specifications provided ensure that these pipes meet stringent industry standards and customer requirements.

HFW Steel Pipe

Both ERW and HFW steel pipes have their unique advantages and applications. ERW pipes are suitable for general purposes where cost-effectiveness and adequate strength are required. In contrast, HFW pipes are preferred for applications demanding superior weld quality and higher strength, especially in the oil and gas industry and high-pressure fluid transport systems. The choice between ERW and HFW will depend on the specific requirements of the project, including the mechanical stress, pressure conditions, and budget constraints.

EFW Steel Pipe

EFW steel pipes are a reliable choice for applications that require large-diameter, high-strength pipes with excellent weld integrity. Their manufacturing process ensures robust and consistent quality, making them suitable for demanding industries like oil and gas, petrochemicals, and large-scale water supply systems. While they may come at a higher cost compared to ERW and HFW pipes, their superior mechanical properties and ability to handle high-pressure conditions justify their use in critical applications.

HFI Steel Pipe | High-Frequency Induction Pipe

Conclusion HFI steel pipes are a reliable and efficient choice for a wide range of applications, offering high-quality welds and consistent dimensions. Their cost-effectiveness and versatility make them a popular option in industries such as oil and gas, construction, and automotive.