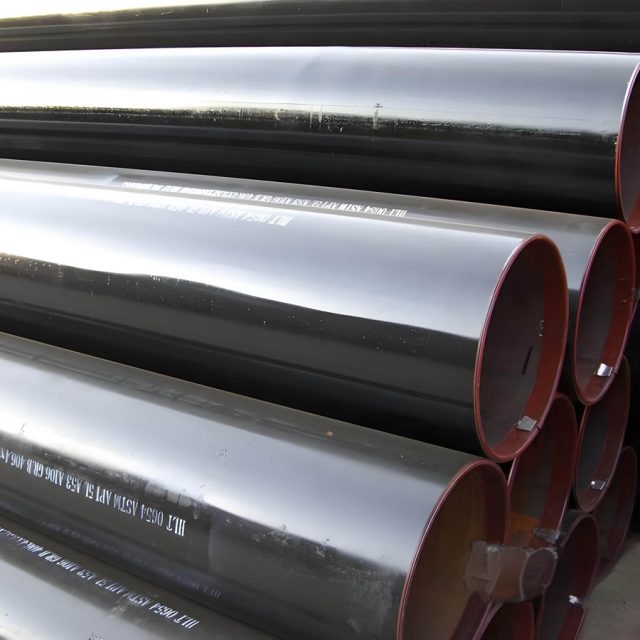

Tubería de acero ERW

Tubería de acero ERW

REG (Soldado por resistencia eléctrica) tubos de acero son un tipo de tubería de acero que se fabrican a través de un proceso de soldadura que emplea resistencia eléctrica. Las tuberías ERW se utilizan en varias aplicaciones debido a su alta calidad, durabilidad, y rentabilidad. Aquí hay una descripción general de las tuberías de acero ERW, su proceso de fabricación, aplicaciones, y beneficios.

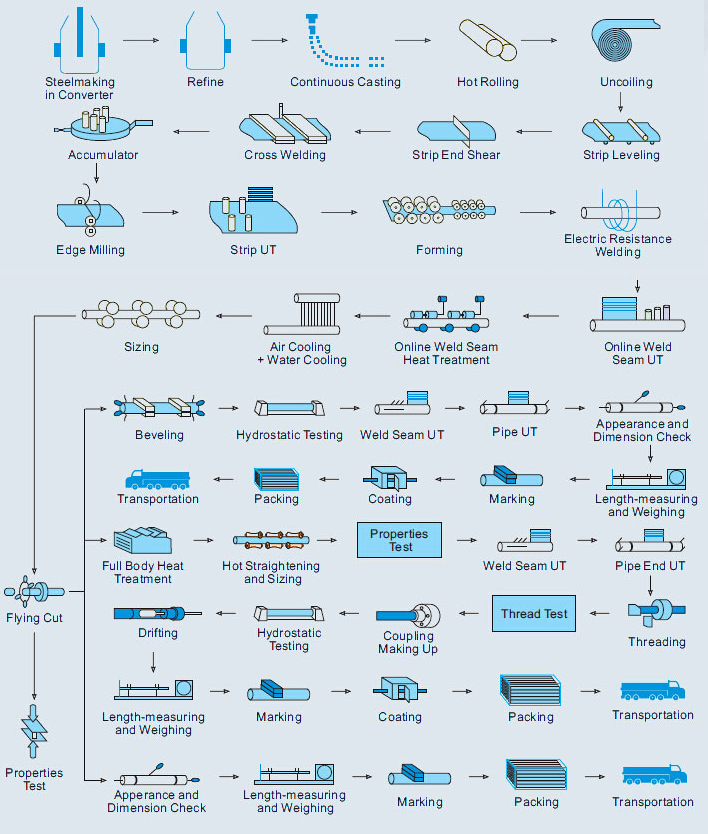

Proceso de fabricación

- Materia prima:

- El proceso de fabricación comienza con bobinas de acero, que se cortan en tiras de ancho apropiado.

- formando:

- Las tiras de acero se pasan a través de una serie de rodillos para formarlas en forma cilíndrica.

- Soldadura:

- Los bordes de la tira de acero cilíndrica se calientan y se presionan mediante soldadura de resistencia eléctrica, Formando una costura continua. A diferencia de otros métodos de soldadura, No se usa material de relleno.

- Refinamiento:

- La costura soldada se recoce (tratado con calor) Para eliminar cualquier tensión residual del proceso de soldadura.

- Luego se corta la tubería a la longitud deseada, y más procesos de acabado como enderezar, con orientación final, y el recubrimiento se puede aplicar.

- Control de calidad:

- Las tuberías de ERW se someten a varias pruebas de control de calidad, incluyendo pruebas ultrasónicas, prueba hidrostática, e inspección visual para garantizar que cumplan con los estándares y especificaciones de la industria.

Diámetro exterior

- Rango: 1/2″ a 28″

Espesor de la pared

- Rango: 1.65 mm a 20 milímetros (Todos los horarios)

Longitud

- Rango: 1 metro a 12 m o según los requisitos del cliente

Estándares

- ASTM 5L

- ASTM A53

- ASTM A178

- ASTM A500/501

- ASTM A691

- ASTM A252

- ASTM A672

- EN 10217

Grados de materiales

- API 5L: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

- ASTM A53: GR.A, GR.B

- EN: S275, S275JR, S355JRH, S355J2H

Extremos de tubería

- Extremo liso

- Extremo biselado

- roscado

Opciones de tratamiento de superficies

- Desnudo

- Pintado de negro

- barnizado

- Galvanizado

- Recubrimientos anticorrosión (3educación física, PP/PE, Recubrimiento FBE, etc.)

Proceso de fabricación

- Estirado en frío

- Laminado en Caliente

Pruebas y garantía de calidad

- Análisis de componentes químicos

- Propiedades mecánicas:

- Resistencia máxima a la tracción

- Fuerza de producción

- Alargamiento

- Propiedades técnicas:

- Prueba de aplanamiento

- Prueba de flexión

- Prueba de dureza

- Prueba de impacto

- Inspección del tamaño exterior

- Prueba hidrostática

- Pruebas no destructivas (END):

- hora del este (Prueba de corrientes de Foucault)

- RT (Prueba radiográfica)

- Utah (Prueba ultrasónica)

Especificación

Especificación:

|

PULGADA

|

DE

(MM)

|

Espesor de la pared huele

|

|||||||

|

Sch 10WT

(milímetros)

|

Sch 20WT

(milímetros)

|

Sch 40WT

(mm)

|

Sch 60WT

(milímetros)

|

Sch80wt (Mm) |

Sch 100WT (milímetros) |

Sch 160WT (Mm) |

XXS (milímetros) |

||

|

1/4"

|

13.7

|

|

|

2.24

|

|

3.02

|

|

|

|

|

3/8"

|

17.1

|

|

|

2.31

|

|

3.2

|

|

|

|

|

1/2"

|

21.3

|

2.11

|

|

2.77

|

|

3.73

|

|

4.78

|

7.47

|

|

3/4″

|

26.7

|

2.11

|

|

2.87

|

|

3.91

|

|

5.56

|

7.82

|

|

1″

|

33.4

|

2.77

|

|

3.38

|

|

4.55

|

|

6.35

|

9.09

|

|

1-1/4″

|

42.2

|

2.77

|

|

3.56

|

|

4.85

|

|

6.35

|

9.7

|

|

1-1/2″

|

48.3

|

2.77

|

|

3.68

|

|

5.08

|

|

7.14

|

10.15

|

|

2″

|

60.3

|

2.77

|

|

3.91

|

|

5.54

|

|

8.74

|

11.07

|

|

2-1/2″

|

73

|

3.05

|

|

5.16

|

|

7.01

|

|

9.53

|

14.02

|

|

3″

|

88.9

|

3.05

|

|

5.49

|

|

7.62

|

|

11.13

|

15.24

|

|

3-1/2″

|

101.6

|

3.05

|

|

5.74

|

|

8.08

|

|

|

|

|

4″

|

114.3

|

3.05

|

4.5

|

6.02

|

|

8.56

|

|

13.49

|

17.12

|

|

5″

|

141.3

|

3.4

|

|

6.55

|

|

9.53

|

|

15.88

|

19.05

|

|

6″

|

168.3

|

3.4

|

|

7.11

|

|

10.97

|

|

18.26

|

21.95

|

|

8″

|

219.1

|

3.76

|

6.35

|

8.18

|

10.31

|

12.7

|

15.09

|

23.01

|

22.23

|

|

10″

|

273

|

4.19

|

6.35

|

9.27

|

12.7

|

15.09

|

18.26

|

28.58

|

25.4

|

|

12″

|

323.8

|

4.57

|

6.35

|

10.31

|

14.27

|

17.48

|

21.44

|

33.32

|

25.4

|

|

14″

|

355

|

6.35

|

7.92

|

11.13

|

15.09

|

19.05

|

23.83

|

36.71

|

|

|

16″

|

406

|

6.35

|

7.92

|

12.7

|

16.66

|

21.44

|

26.19

|

40.49

|

|

|

18″

|

457

|

6.35

|

7.92

|

14.27

|

19.05

|

23.83

|

29.36

|

46.24

|

|

|

20″

|

508

|

6.35

|

9.53

|

15.09

|

20.62

|

26.19

|

32.54

|

50.01

|

|

|

22″

|

559

|

6.35

|

9.53

|

|

22.23

|

28.58

|

34.93

|

54.98

|

|

|

24″

|

610

|

6.35

|

9.53

|

17.48

|

24.61

|

30.96

|

38.89

|

59.54

|

|

|

26″

|

660

|

7.92

|

12.7

|

|

|

|

|

|

|

|

28″

|

711

|

7.92

|

12.7

|

|

|

|

|

|

|

|

30″

|

762

|

7.92

|

12.7

|

|

|

|

|

|

|

|

32″

|

813

|

7.92

|

12.7

|

17.48

|

|

|

|

|

|

|

34″

|

863

|

7.92

|

12.7

|

17.48

|

|

|

|

|

|

|

36″

|

914

|

7.92

|

12.7

|

19.05

|

|

|

|

|

|

|

38″

|

965

|

|

|

|

|

|

|

|

|

|

40″

|

1016

|

|

|

|

|

|

|

|

|

|

42″

|

1066

|

|

|

|

|

|

|

|

|

|

44″

|

1117

|

|

|

|

|

|

|

|

|

|

46″

|

1168

|

|

|

|

|

|

|

|

|

|

48″

|

1219

|

|

|

|

|

|

|

|

|

Estándar

Análisis químico y propiedades mecánicas.

| Estándar | Clase | Calificación | Análisis químico(%) | Propiedades mecánicas(mín.)(MPa) | ||||

| c | Minnesota | PAG | S | Resistencia a la tracción | Fuerza de producción | |||

| API 5L | PSL1 | B | 0.26 | 1.20 | 0.030 | 0.030 | 414 | 241 |

| X42 | 0.26 | 1.30 | 0.030 | 0.030 | 414 | 290 | ||

| X46 | 0.26 | 1.40 | 0.030 | 0.030 | 434 | 317 | ||

| X52 | 0.26 | 1.40 | 0.030 | 0.030 | 455 | 359 | ||

| X56 | 0.26 | 1.40 | 0.030 | 0.030 | 490 | 386 | ||

| X60 | 0.26 | 1.40 | 0.030 | 0.030 | 517 | 414 | ||

| X65 | 0.26 | 1.45 | 0.030 | 0.030 | 531 | 448 | ||

| X70 | 0.26 | 1.65 | 0.030 | 0.030 | 565 | 483 | ||

| PSL2 | B | 0.22 | 1.20 | 0.025 | 0.015 | 414 | 241 | |

| X42 | 0.22 | 1.30 | 0.025 | 0.015 | 414 | 290 | ||

| X46 | 0.22 | 1.40 | 0.025 | 0.015 | 434 | 317 | ||

| X52 | 0.22 | 1.40 | 0.025 | 0.015 | 455 | 359 | ||

| X56 | 0.22 | 1.40 | 0.025 | 0.015 | 490 | 386 | ||

| X60 | 0.22 | 1.40 | 0.025 | 0.015 | 517 | 414 | ||

| X65 | 0.22 | 1.45 | 0.025 | 0.015 | 531 | 448 | ||

| X70 | 0.22 | 1.65 | 0.025 | 0.015 | 565 | 483 | ||

| X80 | 0.22 | 1.85 | 0.025 | 0.015 | 621 | 552 | ||

Proceso

Aplicaciones

Las tuberías de acero ERW se utilizan en una amplia gama de aplicaciones debido a su versatilidad y rentabilidad:

- Industria del petróleo y el gas: Transporte de petróleo, gas, y otros fluidos.

- Sistemas de suministro de agua: Tuberías para sistemas de agua y aguas de agua potable.

- Industria automotriz: Componentes estructurales, sistemas de escape, y otras piezas automotrices.

- Construcción: Aplicaciones estructurales en edificios, puentes, y otros proyectos de infraestructura.

- Ingeniería Mecánica y General: Fabricación de piezas mecánicas y componentes generales de ingeniería.

Beneficios

- Rentable: Las tuberías ERW son generalmente menos costosas que las tuberías sin costuras.

- Alta calidad: El proceso de fabricación garantiza un alto grado de precisión dimensional y uniformidad.

- Resistencia y durabilidad: Las tuberías ERW tienen buenas propiedades mecánicas y son adecuadas para aplicaciones de alta presión.

- Versatilidad: Disponible en varios tamaños, espesores, y longitudes, Hacerlos adecuados para diversas aplicaciones.

- Eficiencia: El proceso ERW es eficiente, Permitir la producción en masa con una calidad consistente.

Tipos de tuberías ERW

- Round Erw Pipes: Comúnmente utilizado en el transporte de fluidos.

- Tuberías ERW cuadradas y rectangulares: A menudo utilizado en aplicaciones estructurales.

- Tuberías ERW galvanizadas: Recubierto con zinc para evitar la corrosión, utilizado en entornos al aire libre y duros.

Estándares y especificaciones

Las tuberías de acero ERW se fabrican para cumplir con varios estándares y especificaciones internacionales, incluido:

- API 5L: Especificación para tuberías de línea.

- ASTM A53: Especificación estándar para tubería, acero, negro y bañado en caliente, recubierto de zinc, soldado y sin costura.

- ASTM A252: Especificación estándar para pilas de tuberías de acero soldadas y sin costuras.

- licenciatura 1387: Especificación para tubos y tubulares de acero atornillados y encajados y para tubos de acero con extremo liso aptos para soldar o atornillar según BS 21 roscas de tubería.

Conclusión

Las tuberías de acero ERW son un componente esencial en diversas industrias debido a su confiabilidad, rentabilidad, y versatilidad. Su proceso de fabricación garantiza un producto de alta calidad que cumpla con los estrictos estándares de la industria, haciéndolos una opción preferida para muchas aplicaciones.