Tubos soldados ERW y proceso de fabricación

Especificación de la tubería de acero ERW

Estándar: ASTM A53, ASTM A106, API 5L, EN10210, EN10219, ASTM A178, ASTM A500/501, ASTM A691, ASTM A252, ASTM A672, EN 10217

Grado de acero: Grado B, X42-X80, S275JR, S275J0H, S275JRH, S355JR, S355J0H, S355JRH

Dimensiones

DE: 1/8 pulgada a 24 pulgada

peso: máx. 26.5 mm

Longitud: Longitud fija o longitud aleatoria, máximo 12 metros

| Tubería ERW de diámetro pequeño | |||||||

| Diámetro exterior | Sch 5 | Sch 10 | Sch 40 | ||||

| Pulgada | milímetros | Espesor | Kg/mtr | Espesor | Kg/mtr | Espesor | Kg/mtr |

| 1/2″ | 21.3 | 1.65 | 0.81 | 2.11 | 1.01 | 2.77 | 1.29 |

| 3/4″ | 26.7 | 1.65 | 1.03 | 2.11 | 1.30 | 2.87 | 1.71 |

| 1″ | 33.4 | 1.65 | 1.31 | 2.77 | 2.12 | 3.38 | 2.54 |

| 1 1/4″ | 42.2 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 1 1/2″ | 48.3 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 2″ | 60.3 | 1.65 | 2.42 | 2.77 | 3.98 | 4.81 | 5.31 |

| 3″ | 88.9 | 2.11 | 4.58 | 3.05 | 6.54 | 5.49 | 11.45 |

| 3 1/2″ | 101.6 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 4″ | 114.3 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 5″ | 141.3 | 2.77 | 9.50 | 3.40 | 11.74 | 6.55 | 22.10 |

| 6″ | 168.3 | 2.77 | 11.47 | 3.40 | 14.04 | 7.11 | 28.68 |

| 8″ | 219.1 | 2.77 | 14.99 | 3.76 | 20.25 | 8.18 | 43.16 |

| Tubería ERW de gran diámetro | |||||||||||||||||||

| DE | peso | ||||||||||||||||||

| Pulgada | milímetros | 8 5/8″ | 219.1

milímetros |

10 3/4″ | 273.1

milímetros |

12 3/4″ | 325.0

milímetros |

14″ | 355.6

milímetros |

16″ | 406.4

milímetros |

18″ | 457.7

milímetros |

20″ | 508.0

milímetros |

24″ | 610

milímetros |

24 4/5″ | 630.0

milímetros |

| 0.157 | 4.0 | —- | — | ||||||||||||||||

| 0.197 | 5.0 | — | — | — | — | — | — | — | — | ||||||||||

| 0.236 | 6.0 | — | — | — | — | — | — | — | — | — | — | — | — | ||||||

| 0.276 | 7.0 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | ||||

| 0.315 | 8.0 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | ||

| 0.354 | 9.0 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | ||

| 0.394 | 10.0 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 0.133 | 11.0 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 0.492 | 12.5 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 0.551 | 14.0 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | ||||

| 0.630 | 16.0 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | ||||

| 0.689 | 17.5 | — | — | — | — | — | — | — | — | — | — | ||||||||

| 0.748 | 19.0 | — | — | — | — | — | — | — | — | ||||||||||

| 0.787 | 20.0 | — | — | — | — | — | — | ||||||||||||

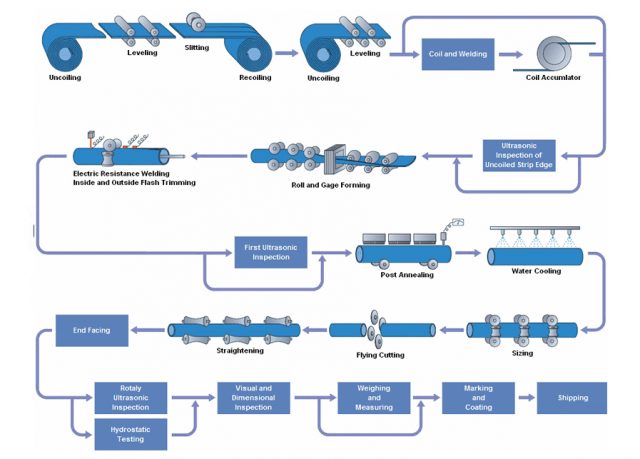

Proceso de fabricación de tuberías soldadas

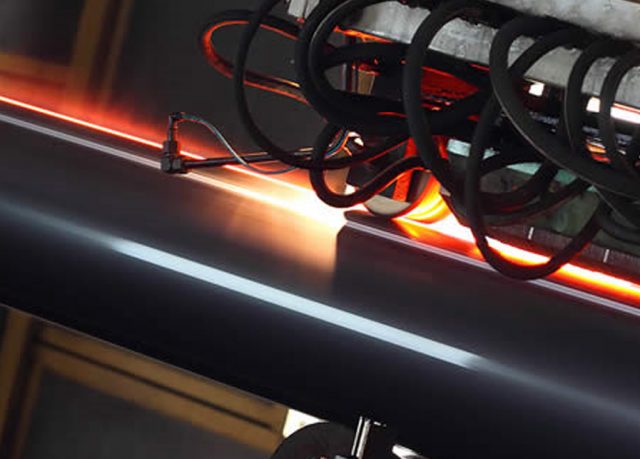

En la soldadura de Erw, Dos electrodos, generalmente hecho de cobre, se utilizan para aplicar presión y corriente. Los electrodos tienen forma de disco y giran a medida que el material pasa entre ellos. Esto permite que los electrodos permanezcan en contacto constante con el material para hacer soldaduras continuas largas.

Un transformador de soldadura suministra bajo voltaje, Alta potencia de CA de corriente. La junta de la tubería tiene una alta resistencia eléctrica en relación con el resto del circuito y la corriente calienta a su punto de fusión.. Las superficies semi-molenadas se presionan junto con una fuerza que crea un enlace de fusión, resultando en una estructura uniformemente soldada.

Método de tratamiento térmico de tubería de acero de carbono y aleación

Los métodos de tratamiento térmico para la tubería de carbono y acero de aleación incluyen 4 principalmente tipos:

Normalizando, Recocido, Temple y revenido.

Mejorará las propiedades mecánicas del material de acero, composición química uniforme, y maquinabilidad. El tratamiento térmico para los materiales de metal de acero se puede dividir en tratamiento térmico integral, Tratamiento térmico de la superficie y tratamiento térmico químico. La tubería de acero generalmente adopta el tratamiento térmico integral.

El rendimiento del material de acero se refiere principalmente a propiedades mecánicas, propiedades físicas, y rendimiento del proceso. El tratamiento térmico traerá diferentes estructuras metalúrgicas y el rendimiento correspondiente para la tubería de acero, Por lo tanto, podría aplicarse mejor en diferentes servicios industriales o de petróleo y gas..

Hay dos métodos para mejorar las propiedades del material de acero.. Un método es ajustar la composición química, Método de aleación nombrado. El otro método es el tratamiento térmico. En el campo de la tecnología industrial moderna, El tratamiento térmico mejore el rendimiento de la tubería de acero en la posición dominante.

Propósitos de tratamiento térmico

1. Calefacción.

El material de acero podría calentarse por debajo del punto crítico o por encima del punto crítico. La antigua forma de calefacción puede estabilizar la estructura y eliminar el estrés residual. La última forma puede hacer que el material sea austenitante. Austenitizar es calentar el metal de acero a lo largo de su temperatura crítica mucho tiempo suficiente, Entonces podría transformarse. Si siguió un enfriamiento después de la austenitación, entonces el material se endurecerá. El enfriamiento tomará lo suficientemente rápido como para transformar la austenita en martensite. Una vez alcanzado la temperatura de austenitización, microestructura adecuada y dureza completa, El material de la tubería de acero se alcanzará en procesos de tratamiento térmico adicionales..

2. Preservación de calor.

El propósito de la preservación del calor es uniforme la temperatura de calentamiento del material de acero, entonces obtendrá una organización de calefacción razonable.

3. Enfriamiento

El proceso de enfriamiento es el proceso clave en el tratamiento térmico., Determina las propiedades mecánicas de la tubería de acero después del proceso de enfriamiento.

Cuatro métodos principales de tratamiento térmico en la industria de tuberías de acero de carbono y aleación Los procesos de tratamiento térmico para la tubería de acero incluyen normalizar, recocido, templado, apagado y otro proceso.

Normalizando

Calentar la tubería de acero por encima de la temperatura crítica, y enfriado en el aire.

A través de la normalización, La tensión del material de acero podría aliviarse, Mejora la ductilidad y la dureza para el proceso de trabajo en frío. La normalización generalmente se aplica para el material de tubería de acero de carbono y baja aleación. Producirá una estructura de metal diferente, perlita, bolito, un poco de martensita. Que trae material de acero cada vez más fuerte, y menos ductilidad que el material de recocido completo.

Recocido

Calentar el material por encima de su temperatura crítica el tiempo suficiente hasta que la microestructura se transforme en austenita. Luego se enfría lento en el horno, Obtenga la máxima transformación de Ferrite y Pearlite.

El recocido eliminará defectos, Uniforme La composición química y los granos finos. Este proceso generalmente se aplica al alto carbono, La tubería de acero de baja aleación y aleación necesita reducir su dureza y resistencia, Refinar la estructura cristalina, mejorar la plasticidad, ductilidad, Dureza y maquinabilidad.

Temple

Calentar el material de la tubería de acero a temperatura crítica hasta que se realice la transformación de la microestructura, enfriándolo a una velocidad rápida.

El propósito de enfriamiento es producir el estrés térmico y el estrés tisular. Puede eliminar y mejorar a través del temple. La combinación de enfriamiento y templado puede mejorar el rendimiento integral.

Templado

Calentar el material de acero a una temperatura precisa por debajo del punto crítico, y a menudo hecho en el aire, al vacío o las atmósferas inerte. Hay temperatura baja de temperatura 205 a 595 ° F (400 a 1105 ° F), temperatura media y temperatura de alta temperatura (a 700 ℃ 1300 ℉).

El propósito del temple es aumentar la tenacidad del acero y la tubería de acero de aleación.. Antes de templar, Estos acero son muy difícil pero demasiado frágil para la mayor aplicación.. Después del proceso puede mejorar la plasticidad y la tenacidad de la tubería de acero, Reduzca o elimine la tensión residual y estabilice el tamaño de la tubería de acero. Trae buenas propiedades mecánicas completas, para que no cambie en el servicio.

Tratamiento de soluciones para material de tubería de acero a base de aleación

Calentar una aleación a una temperatura adecuada, Preservarlo a esta temperatura el tiempo suficiente para causar o más componentes se cambia a una solución sólida, luego enfriarlo a una velocidad rápida para mantener estos componentes en solución.

Hay varias aleaciones basadas en níquel fundidas e forjadas que pueden lograr diferentes rendimientos requeridos a través del tratamiento de soluciones o por endurecimiento por edad de precipitación.. Características como temperatura ambiente y temperatura elevada resistencia mecánica, La resistencia a la corrosión y la resistencia a la oxidación se mejorarán significativamente por este tratamiento térmico. Muchas aleaciones a base de níquel desarrollan sus propiedades deseadas únicamente a través del tratamiento de la solución, como Hastelloy y tubería de acero de aleación de níquel.

Durante el tratamiento de la solución, El carburo y varios elementos de aleación se disuelven uniformemente en la austenita. El enfriamiento rápidamente hará que los elementos de carbono y aleación sean demasiado tarde para precipitar, y obtener el proceso de tratamiento térmico de un solo tejido de austenita. El tratamiento de la solución puede uniforme de la estructura interna y la composión química.. También puede restaurar la resistencia a la corrosión para Hastelloy y tubería de acero de aleación de níquel.