FBE Coated Pipe

What Is FBE Coated Pipe?

Fusion Bonded Epoxy (FBE) coated pipes are steel pipes coated with a protective layer of fusion bonded epoxy. This coating is applied to the pipe surface to prevent corrosion, enhance mechanical strength, and extend the service life of the pipe. FBE coatings are commonly used in the oil and gas industry, water pipelines, and other industrial applications due to their excellent adhesion, durability, and resistance to a variety of environmental factors.

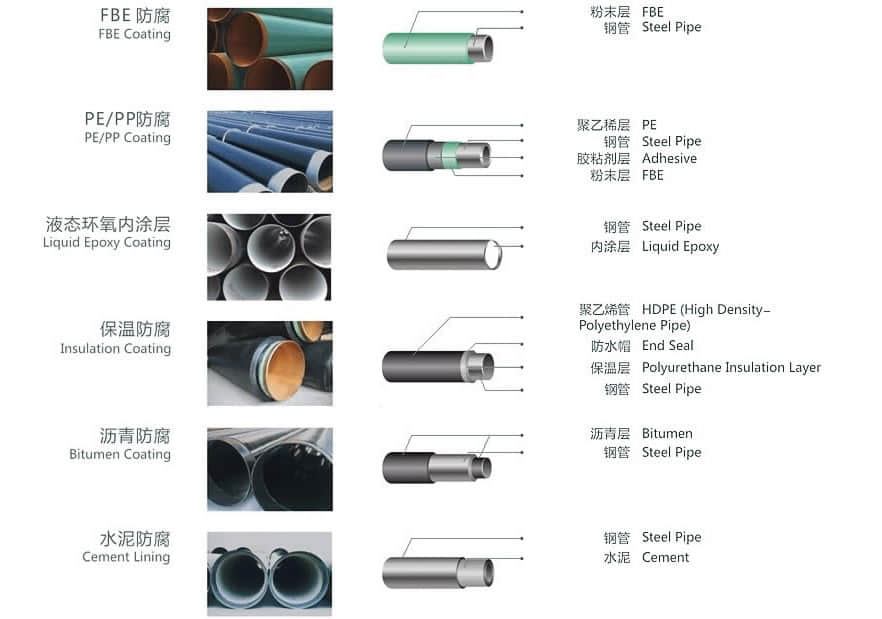

Types Of FBE Coated Pipes

- Single Layer FBE Coated Pipe:

- Description: A single layer of FBE coating is applied to the pipe surface.

- Applications: Suitable for moderate conditions where single-layer protection is sufficient.

- Dual Layer FBE Coated Pipe:

- Description: Consists of two layers of FBE coating. The first layer is a corrosion-resistant layer, and the second layer provides mechanical protection.

- Applications: Used in more demanding environments where enhanced protection is required.

- 3-Layer Polyethylene (3LPE) Coated Pipe:

- Description: Combines a layer of FBE with a copolymer adhesive and an outer layer of polyethylene.

- Applications: Provides excellent corrosion protection and mechanical damage resistance, ideal for buried and submerged pipelines.

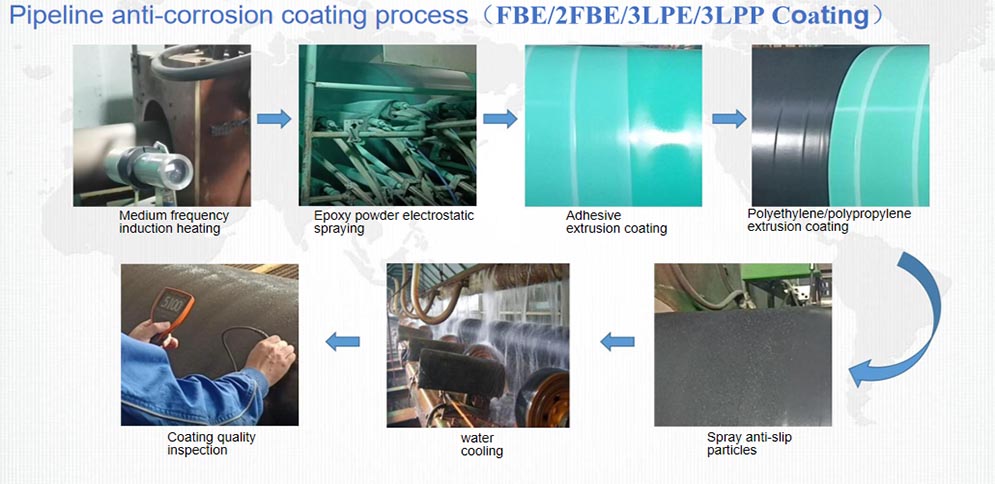

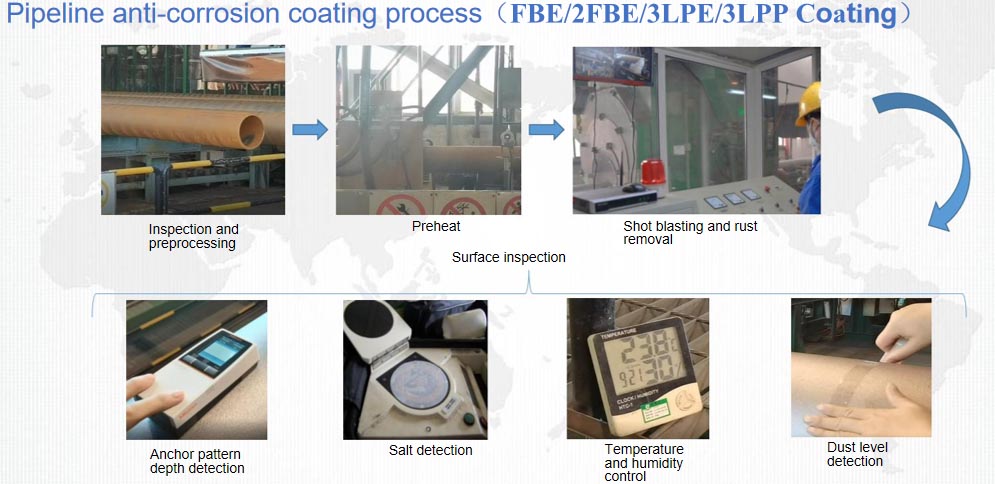

Manufacturing Process Of FBE Coated Pipe

- Pipe Fabrication:

- Steel pipes are manufactured through processes such as electric resistance welding (ERW), submerged arc welding (SAW), or seamless pipe production.

- Surface Preparation:

- The pipe surface is cleaned to remove contaminants, rust, and mill scale using abrasive blasting techniques to achieve a specific cleanliness level.

- Pre-Heating:

- The cleaned pipe is pre-heated to the required temperature, typically between 180°C and 250°C (356°F to 482°F), to prepare for coating application.

- FBE Coating Application:

- The FBE powder is applied to the heated pipe surface using an electrostatic spray gun or fluidized bed process.

- Curing:

- The applied FBE coating melts and cures on the pipe surface, forming a continuous and uniform protective layer.

- Cooling:

- The coated pipe is allowed to cool, solidifying the epoxy coating and ensuring strong adhesion to the pipe surface.

The Process Of FBE Coating Application

- Surface Preparation:

- Abrasive blasting to achieve a clean, rough surface (typically SA 2.5 or near-white blast cleaning).

- Surface roughness is controlled to ensure proper epoxy adhesion.

- Pre-Heating:

- Pipe heating to the specified temperature range (180°C to 250°C).

- Powder Application:

- Electrostatic spray or fluidized bed application of FBE powder onto the hot pipe surface.

- Fusion and Curing:

- The powder melts and fuses to the pipe surface, forming a uniform coating.

- The coating is allowed to cure, forming a hard, cross-linked polymer.

- Cooling:

- The coated pipe is cooled, solidifying the FBE coating.

Advantages Of FBE Coated Pipe

- Corrosion Resistance:

- Provides excellent protection against corrosion, extending the service life of the pipeline.

- Strong Adhesion:

- FBE coatings adhere strongly to the steel surface, ensuring long-lasting protection.

- Mechanical Strength:

- High impact and abrasion resistance make it suitable for harsh environments.

- Chemical Resistance:

- Resistant to various chemicals, making it versatile for different applications.

- Ease of Application:

- Can be applied in a single layer, reducing application time and costs.

- Environmental Safety:

- FBE coatings are environmentally friendly, containing no solvents or volatile organic compounds (VOCs).

Specification

| M kg/m | Layer thickness in mm | ||||||||

| Class A1 | Class A2 | Class A3 | Class B1 | Class B2 | Class B3 | Class C1 | Class C2 | Class C3 | |

| M ≤ 15 | 1,8 | 2,1 | 2,6 | 1,3 | 1,8 | 2,3 | 1,3 | 1,7 | 2,1 |

| 15 < M ≤ 50 | 2,0 | 2,4 | 3,0 | 1,5 | 2,1 | 2,7 | 1,5 | 1,9 | 2,4 |

| 50 < M ≤ 130 | 2,4 | 2,8 | 3,5 | 1,8 | 2,5 | 3,1 | 1,8 | 2,3 | 2,8 |

| 130 < M ≤ 300 | 2,6 | 3,2 | 3,9 | 2,2 | 2,8 | 3,5 | 2,2 | 2,5 | 3,2 |

| 300 < M | 3,2 | 3,8 | 4,7 | 2,5 | 3,3 | 4,2 | 2,5 | 3,0 | 3,8 |

| Please note: The total required thickness may be reduced for SAW pipes by a maximum of 10% on joint seam. Class 1 and 2 for medium and light applications (sandy soil). Class 3 – application in extreme conditions (rocky soil) or underwater. |

|||||||||

Minimum thickness of finished coating

| Pipe Sizes (Specified OD) | Minimum Coating Thickness Chart (mm) |

| ≤ 10 3 /4” (273.1 mm) | 2.5 |

| > 12 3 /4” ( 323.9 mm) to ≤ 18” (457 mm) | 2.8 |

| > 20″ (508.0 mm) to ≤ 30″ (762 mm) | 3.0 |

| > 32″ (813.0 mm) | 3.3 |

THICKNESS OF FBE COATING ON STEEL PIPES

| DN (mm) | Epoxy Powder (μm) | Adhesive Layer (μm) | Min. Thickness on The Coating (mm) | |

| Common Level (G) | Strengthen Level (S) | |||

| DN ≤ 100 | ≥120 | ≥170 | 1.8 | 2.5 |

| 100 < DN ≤250 | 2.0 | 2.7 | ||

| 250 < DN < 500 | 2.2 | 2.9 | ||

| 500 ≤DN < 800 | 2.5 | 3.2 | ||

| DN ≥ 800 | 3.0 | 3.7 | ||

Standard

DIN 30670-2012 Polyethylene Coatings on Steel Pipes and Fittings

ISO 21809-1:2011 Petroleum and natural gas industries — External coatings for buried or submerged pipelines used in pipeline transportation systems — Part 1: Polyolefin coatings (3-layer PE and 3-layer PP)

CAN CSA Z245.21 External Polyethylene Coating for Pipe

NFA 49-710 External Three-Layer Polyethylene Based Coating, Application by Extrusion

SHELL DEP 31.40.30.31-CSPC External Polyethylene and Polypropylene Coating for Line Pipe

Performance Of FBE Coated Pipe

- Corrosion Protection:

- Excellent resistance to moisture, chemicals, and soil conditions.

- Mechanical Performance:

- High impact resistance ensures durability during transportation, handling, and installation.

- Thermal Stability:

- Maintains protective properties over a wide temperature range (-40°C to 85°C).

- Adhesion:

- Strong adhesion to the pipe surface prevents disbondment and ensures long-term protection.

The Service Life Of FBE Coated Pipe

The service life of FBE coated pipes can exceed 30-50 years, depending on factors such as:

- Quality of Surface Preparation: Proper surface cleaning and preparation ensure optimal adhesion and performance.

- Coating Application Quality: Correct application and curing of the FBE coating are critical for long-term protection.|

- Maintenance: Regular inspection and maintenance can help identify and address any potential issues early, extending the service life of the pipeline.

Conclusion

FBE coated pipes offer a robust solution for protecting steel pipelines from corrosion and mechanical damage. Their versatility, combined with excellent performance characteristics, makes them an ideal choice for various industrial applications. Understanding the types, manufacturing process, application steps, and advantages of FBE coated pipes can help in selecting the right product for specific needs, ensuring long-term reliability and efficiency in pipeline systems.

References

- NACE International: Standards and guidelines for corrosion protection and coating applications.

- ISO Standards: Specifications for surface preparation and coating application.

- API (American Petroleum Institute): Standards for pipeline materials and coatings.

- Manufacturer Technical Data Sheets: Detailed information on specific FBE coating products and application procedures.

Additional Resources

- Corrosionpedia: Information and articles on corrosion control methods and materials.

- Pipeline and Gas Journal: Industry news and technical articles on pipeline technology.

- Materials Performance Magazine: Publications on corrosion and materials protection.

By leveraging the benefits of FBE coated pipes, industries can achieve enhanced pipeline integrity, reduced maintenance costs, and extended service life, ensuring safe and efficient operation in demanding environments.