Pipeline anticorrosion

|

Nom du produit

|

Anti corrosion steel pipe

|

|||

|

Taille

|

DE

|

20~406mm(1/2inch~16inch) in theory

|

||

|

Épaisseur

|

1.2~15.7mm

|

|||

|

Longueur

|

Any Length Below 16 Meter

|

|||

|

Standard

|

GB/T3091-2008 ASTM A53 BS1387 BS EN39 ASTM

A500 BS 4568 BS EN31 |

|||

|

Matériel

|

Chinese Grade

|

Q215 Q235 According to GB/T700;Q345 According to

GB/T1591 |

||

|

Foreign Grade

|

ASTM

|

Catégorie B,Catégorie C,Catégorie D,Grade 50

|

||

|

DANS

|

S185,S235JR,S235JO,E335,S355JR,S355J2

|

|||

|

IL

|

SS330,SS400,SPFC590

|

|||

|

Usage

|

Used For Water, Gas, Stream, Combustible Fluids And

Other Liquid Delivery |

|||

|

Se termine

|

Plaine, Beveled, Thread With Couplings Or Sockets;

|

|||

|

Plastic Caps And Steel Rings Can Be Provided If Possible

|

||||

|

Surface

|

Bared, Galvanisé, Oiled, Color Paint, 3PE; Or Other

Anti-corrosive Treatment |

|||

|

Inspection

|

With Chemical Composition and Mechanical Properties

Analyse; |

|||

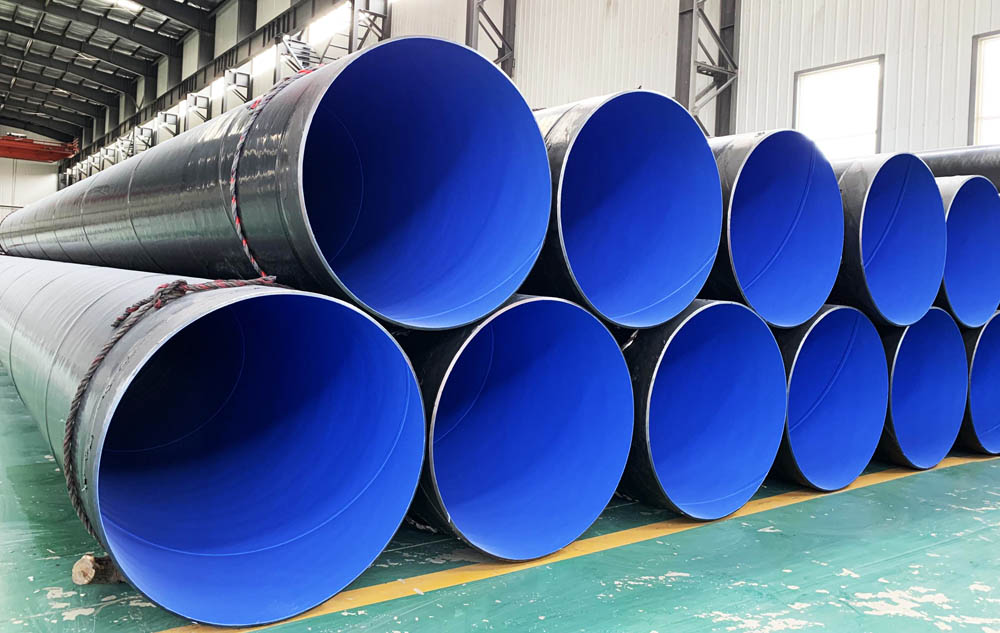

Products Show

Why use anti-corrosion pipes?

Pipelines that transport and distribute oil, gaz, produits chimiques, eau, vapeur, petroleum products and other substances are of critical significance for the economy. And the health of these critical assets is severely endangered by electrochemical deterioration, or corrosion.

Pipeline corrosion is the deterioration of pipe material and the related system due to its interaction with the working environment. It affects pipeline and accessories made of both metals and non-metals. Pipeline corrosion—and the related catastrophic failures that it can cause—cost billions of dollars to the economy. A study released by the U.S. Federal Highway Administration in 2002 estimated that the direct cost of corrosion in the United States was $276 billion each year, or about 3% of the nation’s GDP.

In other words, corrosion is a big problem. It predominantly affects pipelines made of metals such as copper, aluminium, cast iron, acier au carbone, stainless steel and alloy steel pipes used for buried, underground, submerged or other pipelines. That makes designing and selecting the best available systems and materials for pipelines and their corrosion protection systems an extremely important issue for the oil and gas industry. Federal regulations also require that all high-risk pipelines carrying oil, gas or other hazardous substances incorporate reliable and effective pipe materials and coatings, as well as cathodic protection.

What is the definition of anti-corrosion pipe?

Pipeline corrosion is a natural deterioration and destruction of pipe material and essential properties due to electrochemical and other ingredient reactions of pipeline materials with their environment – on the inside as well as outside surfaces. Like any other naturally occurring hazard, a pipeline corrosion can result in a life threatening failure and expensive damage to the pipeline and related system.

The study of pipeline corrosion is geared toward the following:

Prevention of life threatening failures

Measurement of the deterioration process

Understanding and controlling the causes of pipeline material deterioration

Taking corrective action to prevent further deterioration

Leader mondial en matière de systèmes anticorrosion pour l'industrie des pipelines.

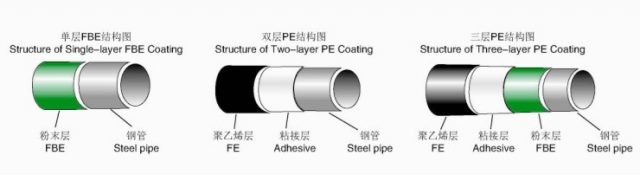

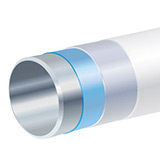

3LPE

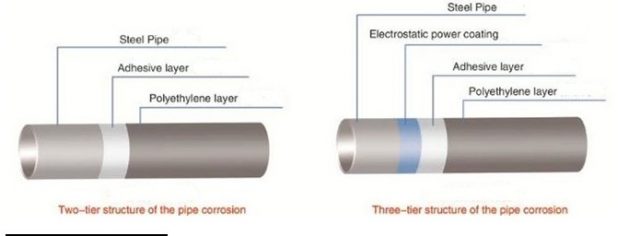

Abter is the world’s leading provider of 3-Layer Polyethylene Systems (3LPE), a multilayer coating composed of three functional components: a high-performance Fusion-Bonded Epoxy (FBE), followed by a copolymer adhesive and an outer layer of polyethylene which provides tough, durable protection. 3LPE systems provide excellent pipeline protection for small and large-diameter pipelines with moderately high operating temperatures.

3LPP

3-Layer Polypropylene (3LPP) consists of a high-performance FBE layer, followed by a copolymer adhesive and an outer layer of polypropylene, which provides the toughest, most durable pipe coating solution available.

LAT-FBE

Low Application Temperature Fusion Bond Epoxy (LAT-FBE) is a plant-applied powder coating for strain-based pipeline designs that require a low application temperature.

FBE

Époxy lié par fusion (FBE) is a high-performance anti-corrosion coating that provides excellent protection for small and large diameter pipelines with moderate operating temperatures.

Asphalt Enamel

Asphalt Enamel (AE) is a plant-applied durable coating based on modified bitumen (asphalte) that has been successfully used for many years for corrosion protection of steel pipes.

HPPC

High-Performance Powder Coating (HPPC) is designed to protect buried oil and gas pipelines in environments where superior mechanical protection, moisture and corrosion resistance, and moderate to high operating performance characteristics are required.

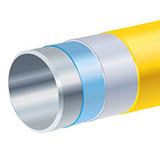

Yellow anti-corrosion systems

Yellow Jacket provides external protection for pipe used in the oil and gas and waterworks industries, where moderate operating temperatures and good handling capabilities are required.

Dual-Layer FBE

Dual-Layer Abrasion-Resistant FBE systems provide excellent properties for a variety of service applications which may include directional drilling and anti-abrasion for road and river crossings, and elevated temperatures in wet environments and anti-slip applications.

YJ2K™

YJ2K was developed for buried oil and gas pipelines in environments where superior adhesion, impact, cathodic disbondment and moderate to high operating temperature properties are required.

high-performance FBE

high-performance FBE is a novel anti-corrosion coating composed of a high-performance fusion-bonded epoxy (FBE), followed by an outer layer of reinforced polymeric coating, providing a tough and durable pipe coating solution. SureBond 100 systems provide excellent pipeline protection for small and large-diameter pipelines with higher than normal operating temperatures.

2-layer corrosion protection system

2-layer corrosion protection system that combines the proven protective qualities of a polyethylene outer coating with a special butyl rubber adhesive.