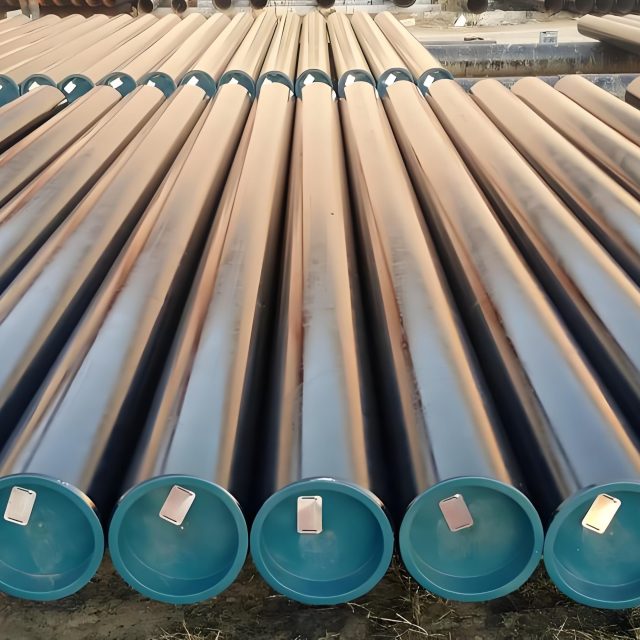

HFW Steel Pipe

HFW Steel Pipe

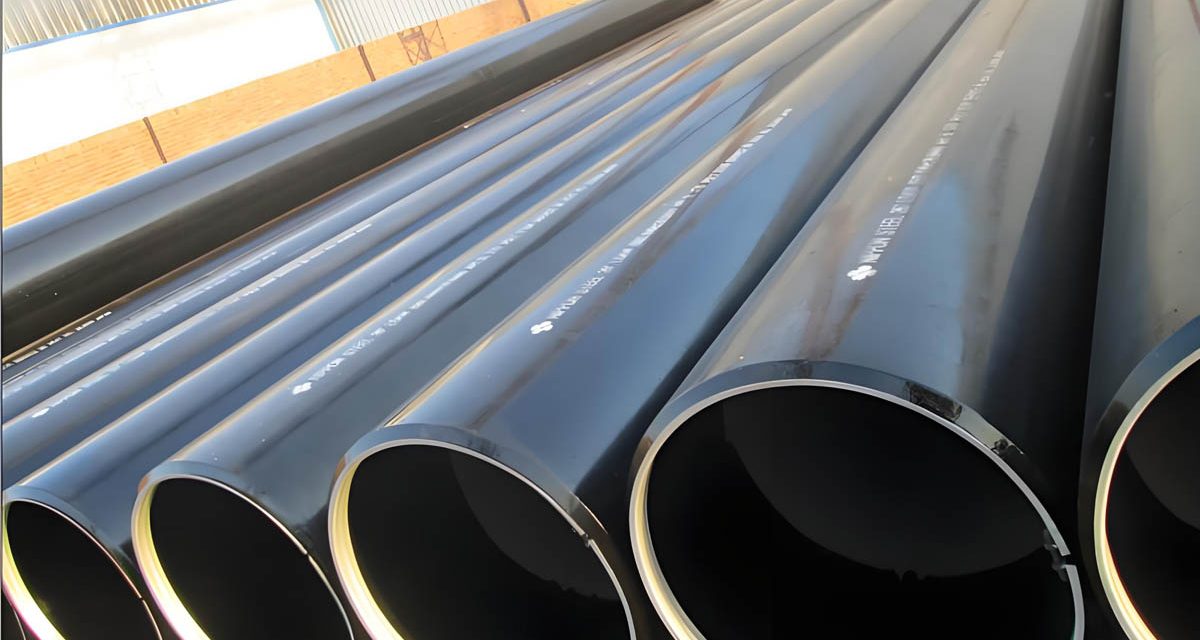

HFW (High-Frequency Welded) steel pipes are a type of Electric Resistance Welded (ERW) pipe. The primary distinction between HFW and traditional ERW pipes lies in the frequency of the welding current used during production. HFW pipes are created using high-frequency current, which enhances the welding process and the overall quality of the weld seam.

Key Features of HFW Steel Pipes

- Welding Method: Uses high-frequency electric currents to weld the seam.

- Precision: Offers precise control over the welding process, resulting in high-quality welds.

- Efficiency: Suitable for high-speed production, making it cost-effective for large-scale manufacturing.

Specifications

Outer Diameter

- Range: 1/2″ to 28″

Wall Thickness

- Range: 1.65 mm to 20 mm (All Schedules)

Length

- Range: 1 m to 12 m or as per customer requirements

Standards

- API 5L

- ASTM A53

- ASTM A178

- ASTM A500/501

- ASTM A691

- ASTM A252

- ASTM A672

- EN 10217

Material Grades

- API 5L: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

- ASTM A53: GR.A, GR.B

- EN: S275, S275JR, S355JRH, S355J2H

Pipe Ends

- Plain End

- Beveled End

- Threaded

Surface Treatment Options

- Bare

- Painted Black

- Varnished

- Galvanized

- Anti-corrosion coatings (3PE, PP/EP, FBE coating, etc.)

Manufacturing Process

- Cold Drawn

- Hot Rolled

Testing and Quality Assurance

- Chemical Component Analysis

- Mechanical Properties:

- Ultimate tensile strength

- Yield strength

- Elongation

- Technical Properties:

- Flattening Test

- Bending Test

- Hardness Test

- Impact Test

- Exterior Size Inspection

- Hydrostatic Test

- Non-Destructive Testing (NDT):

- ET (Eddy Current Test)

- RT (Radiographic Test)

- UT (Ultrasonic Test)

HFW Steel Pipe Specification: Chemical Analysis and Mechanical Properties

Chemical Analysis

The chemical composition of HFW steel pipes varies based on the material grade and specific standards. Below are typical ranges for chemical elements in some common grades:

API 5L Grades: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

| Element | Max % (Gr.A & Gr.B) | Max % (X42 to X70) |

|---|---|---|

| Carbon (C) | 0.28 | 0.28 |

| Manganese (Mn) | 1.20 | 1.40 |

| Phosphorus (P) | 0.030 | 0.030 |

| Sulfur (S) | 0.030 | 0.030 |

| Silicon (Si) | 0.45 | 0.45 |

| Vanadium (V) | 0.10 | 0.10 |

| Niobium (Nb) | 0.05 | 0.05 |

| Titanium (Ti) | 0.04 | 0.04 |

ASTM A53 Grades: GR.A, GR.B

| Element | Max % (GR.A) | Max % (GR.B) |

|---|---|---|

| Carbon (C) | 0.25 | 0.30 |

| Manganese (Mn) | 0.95 | 1.20 |

| Phosphorus (P) | 0.05 | 0.05 |

| Sulfur (S) | 0.045 | 0.045 |

| Copper (Cu) | 0.40 | 0.40 |

| Nickel (Ni) | 0.40 | 0.40 |

| Chromium (Cr) | 0.40 | 0.40 |

| Molybdenum (Mo) | 0.15 | 0.15 |

EN Grades: S275, S275JR, S355JRH, S355J2H

| Element | Max % (S275/S275JR) | Max % (S355JRH/S355J2H) |

|---|---|---|

| Carbon (C) | 0.20 | 0.22 |

| Manganese (Mn) | 1.50 | 1.60 |

| Phosphorus (P) | 0.025 | 0.025 |

| Sulfur (S) | 0.025 | 0.025 |

| Silicon (Si) | 0.60 | 0.60 |

Mechanical Properties

Mechanical properties are crucial for determining the suitability of HFW steel pipes for various applications. Below are the typical mechanical properties for some common grades:

API 5L Grades: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

| Property | Gr.A/Gr.B | X42 | X46 | X52 | X56 | X60 | X65 | X70 |

|---|---|---|---|---|---|---|---|---|

| Yield Strength (MPa) | 241/241 | 290 | 317 | 359 | 386 | 414 | 448 | 483 |

| Tensile Strength (MPa) | 414/414 | 414 | 434 | 455 | 490 | 517 | 531 | 565 |

| Elongation (%) | 20/20 | 23 | 22 | 21 | 20 | 19 | 18 | 17 |

ASTM A53 Grades: GR.A, GR.B

| Property | GR.A | GR.B |

|---|---|---|

| Yield Strength (MPa) | 205 | 240 |

| Tensile Strength (MPa) | 330 | 415 |

| Elongation (%) | 25 | 22 |

EN Grades: S275, S275JR, S355JRH, S355J2H

| Property | S275/S275JR | S355JRH/S355J2H |

|---|---|---|

| Yield Strength (MPa) |

Applications

Due to their high-quality welds and strength, HFW steel pipes are used in a variety of demanding applications:

- Oil and Gas Industry: For transportation of oil, gas, and other fluids in both onshore and offshore environments.

- Water Supply Systems: Pipes for potable water, sewage, and other water conveyance systems.

- Construction: Structural applications, including building frameworks, bridges, and other infrastructure projects.

- Automotive Industry: Production of components such as frames, exhaust pipes, and other structural parts.

- Mechanical and General Engineering: Fabrication of mechanical parts and various engineering components.

Benefits

- High-Quality Welds: The high-frequency welding process creates strong, consistent welds with minimal defects.

- Cost-Effective: Efficient production process reduces costs, especially for large-scale manufacturing.

- Strength and Durability: Suitable for high-pressure and structural applications due to excellent mechanical properties.

- Versatility: Available in a wide range of sizes, thicknesses, and lengths, catering to diverse applications.

Conclusion

HFW steel pipes offer a combination of high-quality welds, strength, and cost-effectiveness, making them a preferred choice for many industrial applications. The use of high-frequency currents in the welding process ensures superior weld integrity and performance, meeting stringent industry standards and customer requirements.

ERW vs. HFW Steel Pipes

ERW (Electric Resistance Welded) pipes and HFW (High-Frequency Welded) pipes are both types of welded pipes, but they differ in their welding processes and the applications they are most suitable for. Below is a detailed comparison between the two:

Electric Resistance Welded (ERW) Pipes

ERW pipes are manufactured by rolling metal and then welding it longitudinally across its length. The welding process involves the application of pressure and passing an electric current through the contact points of the metal, which heats the edges and fuses them together.

Key Features:

- Welding Method: Uses low-frequency or high-frequency current to weld the seam.

- Production Process: Suitable for mass production, especially for pipes with smaller diameters.

- Cost: Generally more cost-effective due to the efficiency of the production process.

Applications:

- Water and Gas Conveyance: Widely used in the transportation of water, gas, and other fluids.

- Structural Applications: Commonly used in scaffolding, fencing, and other structural applications.

- Automotive Industry: Utilized in the manufacturing of parts like exhaust systems and chassis components.

Advantages:

- Cost-Effective: Efficient and economical production process.

- Consistency: Uniform wall thickness and smooth surfaces.

- Availability: Widely available in various sizes and lengths.

High-Frequency Welded (HFW) Pipes

HFW pipes are a subset of ERW pipes, distinguished by the use of high-frequency current (typically above 70 kHz) in the welding process. This high-frequency welding method results in superior weld quality and enhanced mechanical properties.

Key Features:

- Welding Method: Uses high-frequency current to create a more precise and stronger weld.

- Quality: Produces high-quality welds with minimal defects, making it suitable for high-stress applications.

- Strength: Generally stronger and more reliable than traditional ERW pipes due to the high-frequency welding process.

Applications:

- Oil and Gas Industry: Used for transporting oil and gas due to its high strength and reliability.

- High-Pressure Applications: Suitable for high-pressure fluid transportation systems.

- Structural and Mechanical Applications: Preferred in constructions requiring high strength and durability.

Advantages:

- Superior Weld Quality: High-frequency welding results in stronger and more consistent welds.

- Higher Strength: Better suited for applications requiring high mechanical stress.

- Durability: Enhanced resistance to fatigue and failure under cyclic loading.

Comparison Summary

| Feature/Aspect | ERW Pipes | HFW Pipes |

|---|---|---|

| Welding Method | Low-frequency or high-frequency current | High-frequency current |

| Weld Quality | Good | Superior |

| Strength | Adequate for most applications | Higher, suitable for high-stress applications |

| Cost | More cost-effective | Slightly higher due to superior quality |

| Applications | Water, gas conveyance, structural, automotive | Oil and gas, high-pressure, structural |