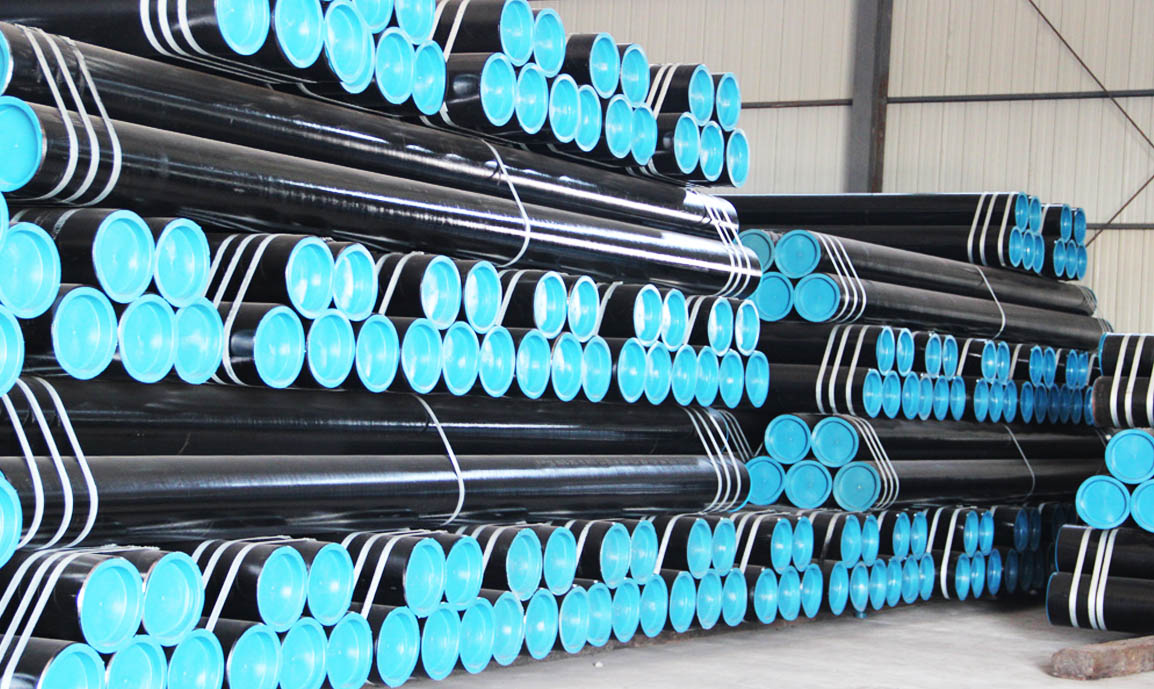

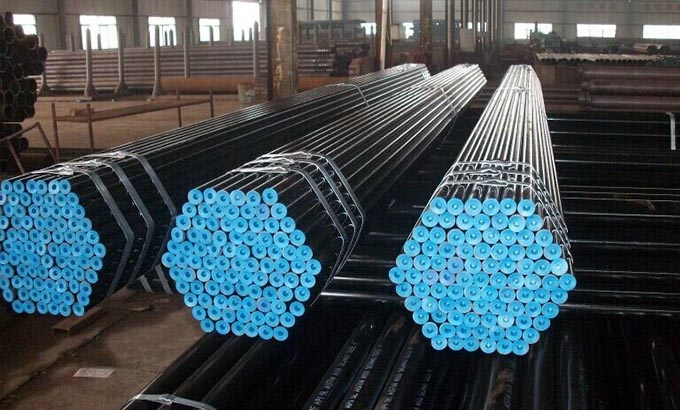

High-Pressure Cylinder Pipes

High-Pressure Cylinder Pipes: Standards Overview

High-pressure cylinder pipes must adhere to stringent standards to ensure safety, durability, and performance. Below, we delve into some key standards governing the manufacture of seamless steel tubes for high-pressure gas cylinders.

Relevant Standards

- GB 18248: Seamless Steel Tubes for Gas Cylinder

- GB 28884: Seamless Steel Tubes for Large Volume Gas Cylinder

- ASTM A519: Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

- JIS G3429: Seamless Steel Tubes for High-Pressure Gas Cylinder

GB 18248: Seamless Steel Tubes for Gas Cylinder

Scope:

- This Chinese standard specifies the requirements for seamless steel tubes used in the manufacture of gas cylinders.

Key Features:

- Materials: Typically includes carbon steel and alloy steel.

- Manufacturing Process: Seamless manufacturing, which involves piercing and elongation of a billet.

- Testing: Includes hydrostatic testing, nondestructive testing (NDT), and mechanical property tests to ensure the tubes can withstand high pressures.

Applications:

- Used in the production of gas cylinders for industrial gases, medical gases, and other high-pressure applications.

GB 28884: Seamless Steel Tubes for Large Volume Gas Cylinder

Scope:

- This standard covers the requirements for seamless steel tubes used in large volume gas cylinders.

Key Features:

- Materials: Emphasizes higher strength carbon and alloy steels.

- Manufacturing Process: Involves advanced techniques to ensure uniformity and strength across larger dimensions.

- Testing: Extensive testing protocols, including mechanical tests, hardness tests, and hydrostatic tests, to ensure safety and performance under high pressures.

Applications:

- Used for large volume gas storage, such as in industrial gas transport and storage systems.

ASTM A519: Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

Scope:

- This American standard specifies the requirements for seamless carbon and alloy steel tubing used in mechanical applications, including high-pressure gas cylinders.

Key Features:

- Materials: Includes a wide range of carbon and alloy steels.

- Manufacturing Process: Seamless manufacturing with precision sizing.

- Testing: Includes chemical composition analysis, mechanical testing (tensile, hardness, and impact tests), and dimensional inspections.

Applications:

- Used in mechanical and pressure applications, such as gas cylinders, hydraulic systems, and various industrial applications requiring high strength and precision.

JIS G3429: Seamless Steel Tubes for High-Pressure Gas Cylinders

Scope:

- This Japanese standard specifies the requirements for seamless steel tubes used in high-pressure gas cylinders.

Key Features:

- Materials: Typically includes high-strength carbon and alloy steels.

- Manufacturing Process: Seamless manufacturing process ensuring high uniformity and strength.

- Testing: Comprehensive testing including hydrostatic tests, mechanical property tests, and nondestructive testing to ensure reliability under high-pressure conditions.

Applications:

- Used primarily in the manufacture of high-pressure gas cylinders for industrial and medical applications, ensuring safe and reliable gas storage and transportation.

Summary

High-pressure cylinder pipes must meet rigorous standards to ensure their safety, reliability, and performance. The standards listed—GB 18248, GB 28884, ASTM A519, and JIS G3429—provide detailed guidelines on material specifications, manufacturing processes, and testing requirements. These standards ensure that the seamless steel tubes used in high-pressure gas cylinders can safely withstand the demanding conditions of high-pressure gas storage and transport.

By adhering to these standards, manufacturers can produce high-quality, reliable high-pressure cylinders that meet the needs of various industries, from industrial gas supply to medical oxygen delivery.

JIS G3429: Seamless Steel Pipe for High-Pressure Gas Cylinders

The Japanese Industrial Standard (JIS) G3429 specifies the requirements for seamless steel pipes used in the manufacture of high-pressure gas cylinders. This standard ensures that the pipes possess the necessary mechanical properties and quality to safely contain gases under high pressure.

Scope

JIS G3429 covers seamless steel pipes intended for use in the production of high-pressure gas cylinders. These pipes must meet stringent criteria to ensure safety, durability, and performance in high-pressure environments.

Key Features

Materials

- Steel Grades: JIS G3429 specifies several grades of steel, each with its chemical composition and mechanical properties. Common grades include:

- STH 11

- STH 12

- STH 21

- STH 22

Chemical Composition

- The standard provides detailed chemical composition limits for each grade, including elements such as carbon (C), manganese (Mn), phosphorus (P), sulfur (S), silicon (Si), and others as necessary.

Mechanical Properties

- Tensile Strength: The minimum tensile strength required varies by grade but generally ensures the pipe can withstand the high pressures encountered in gas cylinder applications.

- Yield Strength: Specifies the minimum yield strength, ensuring the pipe maintains its shape and integrity under pressure.

- Elongation: Requirements for elongation ensure the pipe has sufficient ductility to deform without breaking.

Manufacturing Process

- Seamless Process: Pipes are manufactured through a seamless process, which typically involves piercing a solid billet followed by elongation and rolling to achieve the desired dimensions.

- Heat Treatment: Pipes may undergo heat treatment processes such as normalizing or quenching and tempering to achieve the required mechanical properties.

Dimensions and Tolerances

- Wall Thickness: The standard specifies the nominal wall thickness for different pipe sizes, along with permissible tolerances.

- Outer Diameter: Nominal outer diameters and their tolerances are defined to ensure proper fitting and performance.

Testing

- Hydrostatic Testing: Each pipe must undergo hydrostatic testing to verify its ability to withstand internal pressure without leaking or deforming.

- Nondestructive Testing: Includes ultrasonic testing and other methods to detect internal and surface defects.

- Mechanical Testing: Tensile tests, hardness tests, and impact tests are performed to verify mechanical properties.

Surface Finish

- Surface Condition: Pipes should be free from defects such as cracks, seams, and inclusions that could compromise their integrity under pressure.

- Surface Treatment: Pipes may receive surface treatments such as coating or painting to enhance corrosion resistance.

Applications

Pipes manufactured according to JIS G3429 are used in the production of high-pressure gas cylinders. These cylinders are essential in various applications, including:

- Industrial Gases: Storage and transport of gases like oxygen, nitrogen, helium, and argon for industrial processes.

- Medical Gases: Storage of medical-grade oxygen and other gases used in healthcare facilities.

- Compressed Natural Gas (CNG): High-pressure storage cylinders for CNG used in vehicles and fueling stations.

- Firefighting Equipment: High-pressure cylinders for storing gases used in firefighting systems.

JIS G3429: Seamless Steel Pipe for High-Pressure Gas Cylinders

JIS G3429 is a Japanese Industrial Standard that specifies requirements for seamless steel pipes used in the manufacture of high-pressure gas cylinders. Below are the details regarding the chemical composition and mechanical properties of these pipes.

Chemical Composition

The chemical composition of the steel grades specified in JIS G3429 ensures that the pipes have the necessary properties to withstand high pressures. The standard defines several grades, with typical compositions as follows:

Common Steel Grades and Their Chemical Composition

| Grade | C (%) | Si (%) | Mn (%) | P (%) (max) | S (%) (max) | Cr (%) | Mo (%) |

|---|---|---|---|---|---|---|---|

| STH 11 | 0.25 max | 0.35 max | 0.30-0.80 | 0.030 | 0.030 | – | – |

| STH 12 | 0.35 max | 0.35 max | 0.30-1.00 | 0.030 | 0.030 | – | – |

| STH 21 | 0.25 max | 0.35 max | 0.30-0.80 | 0.030 | 0.030 | 0.90-1.20 | 0.15-0.30 |

| STH 22 | 0.35 max | 0.35 max | 0.30-1.00 | 0.030 | 0.030 | 0.90-1.20 | 0.15-0.30 |

- Carbon (C): Provides strength and hardness.

- Silicon (Si): Acts as a deoxidizer and improves strength.

- Manganese (Mn): Improves strength and toughness.

- Phosphorus (P) and Sulfur (S): Kept to a minimum to avoid brittleness.

- Chromium (Cr) and Molybdenum (Mo): Enhance strength, hardenability, and corrosion resistance in alloy grades.

Mechanical Properties

The mechanical properties of JIS G3429 seamless steel pipes ensure that they can withstand the pressures encountered in high-pressure gas cylinders. The standard specifies requirements for tensile strength, yield strength, and elongation.

Common Steel Grades and Their Mechanical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| STH 11 | ≥ 540 | ≥ 345 | ≥ 20 |

| STH 12 | ≥ 635 | ≥ 375 | ≥ 18 |

| STH 21 | ≥ 540 | ≥ 345 | ≥ 20 |

| STH 22 | ≥ 635 | ≥ 375 | ≥ 18 |

- Tensile Strength: The maximum stress that the material can withstand while being stretched or pulled before breaking.

- Yield Strength: The stress at which a material begins to deform plastically.

- Elongation: The percentage increase in length before the material breaks, indicating ductility.

Additional Properties

- Hardness: The standard may specify hardness ranges for certain grades to ensure the material’s resistance to deformation.

- Impact Strength: For applications requiring toughness, impact testing (e.g., Charpy V-notch) may be conducted to ensure the material can absorb energy without fracturing.

Summary

JIS G3429 specifies the chemical composition and mechanical properties of seamless steel pipes used in high-pressure gas cylinders to ensure they can safely contain gases under high pressure. The standard outlines specific grades with defined chemical compositions and mechanical properties, ensuring that the pipes have the necessary strength, toughness, and ductility for high-pressure applications. By adhering to these specifications, manufacturers can produce reliable and safe high-pressure gas cylinders for various industrial, medical, and safety applications.