INCONEL alloy 625 steel tube | UNS N06625 | WNR 2.4856

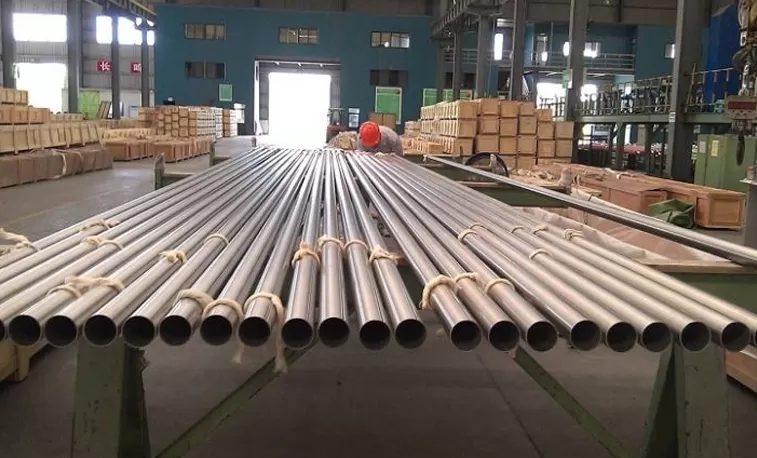

INCONEL Alloy 625 Steel Tube

INCONEL alloy 625 is a nickel-chromium-molybdenum alloy known for its high strength, excellent fabricability (including joining), and outstanding corrosion resistance. It is particularly resistant to pitting and crevice corrosion. This alloy is widely used in various industries, including aerospace, marine, and chemical processing, due to its versatility and robustness.

Specifications:

- UNS N06625

- WNR 2.4856

Typical Manufacturing Specifications

- ASTM B444: Specification for Nickel-Chromium-Molybdenum-Columbium Alloy (UNS N06625) Seamless Pipe and Tube

- ASTM B443: Specification for Nickel-Chromium-Molybdenum-Columbium Alloy (UNS N06625) Plate, Sheet, and Strip

- ASME SB444: Seamless and Welded Pipe

- AMS 5666: Nickel Alloy, Corrosion and Heat-Resistant, Bars, Forgings, Extrusions, and Rings

Chemical Composition

The chemical composition of INCONEL alloy 625 is as follows:

| Element | Composition (wt%) |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0–23.0 |

| Molybdenum (Mo) | 8.0–10.0 |

| Niobium (Nb) | 3.15–4.15 |

| Iron (Fe) | 5.0 max |

| Cobalt (Co) | 1.0 max |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.50 max |

| Aluminum (Al) | 0.40 max |

| Titanium (Ti) | 0.40 max |

| Carbon (C) | 0.10 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

Mechanical Properties

INCONEL alloy 625 exhibits excellent mechanical properties, making it suitable for high-stress environments. Typical mechanical properties include:

- Tensile Strength: 830 MPa (120 ksi) min

- Yield Strength (0.2% offset): 415 MPa (60 ksi) min

- Elongation: 30% min

- Hardness: 30-40 HRC

Physical Properties

- Density: 8.44 g/cm³ (0.305 lb/in³)

- Melting Range: 1290-1350°C (2350-2460°F)

- Specific Heat Capacity: 0.098 cal/g-°C (at 20°C)

- Thermal Conductivity: 9.8 W/m·K (at 20°C)

- Electrical Resistivity: 1.27 µΩ·m (at 20°C)

- Modulus of Elasticity: 205 GPa (at 20°C)

- Poisson’s Ratio: 0.33 (at 20°C)

Key Features and Benefits

- Corrosion Resistance:

- Outstanding resistance to a wide range of corrosive environments, including seawater and industrial acids.

- Resistant to pitting, crevice corrosion, and intergranular attack.

- High Strength:

- Maintains high strength and toughness at both cryogenic and elevated temperatures.

- Excellent fatigue and thermal fatigue strength.

- Fabricability:

- Good weldability and workability, making it easy to fabricate into complex shapes.

- Can be hot- and cold-formed with relative ease.

- Oxidation Resistance:

- Exceptional resistance to oxidation and scaling at high temperatures.

- Suitable for service in extreme environments, including aerospace and power generation.

Applications

INCONEL alloy 625 is used in a variety of applications across multiple industries, including:

- Aerospace: Engine exhaust systems, turbine shroud rings, and bellows.

- Marine: Submarine propulsion systems, seawater equipment, and marine exhaust systems.

- Chemical Processing: Heat exchangers, reactor vessels, and plant equipment handling corrosive substances.

- Power Generation: High-temperature furnace components and heat exchanger tubing.

- Oil and Gas: Downhole equipment, riser systems, and flue gas desulfurization systems.

Conclusion

INCONEL alloy 625 (UNS N06625, WNR 2.4856) is a highly versatile material known for its exceptional strength, corrosion resistance, and fabrication capabilities. Its unique combination of properties makes it an ideal choice for demanding applications in a wide range of industries.