INCONEL alloy 718 steel tube | UNS N07718 / W.Nr. 2.4668

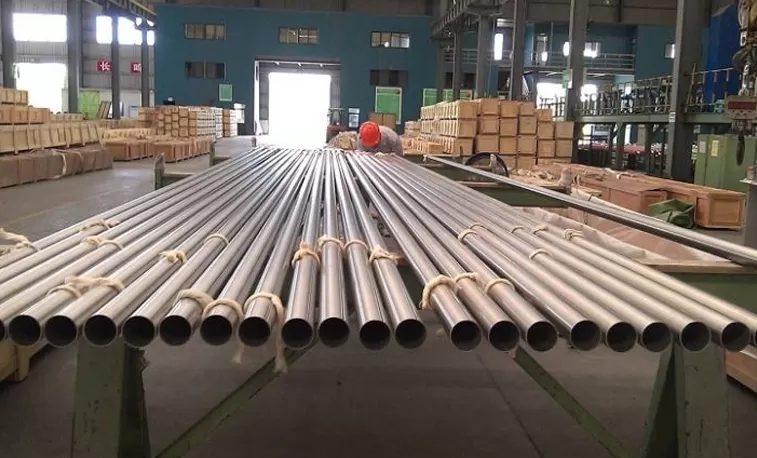

INCONEL Alloy 718 Steel Tube

INCONEL alloy 718 is a high-strength, corrosion-resistant nickel-chromium material used at temperatures ranging from cryogenic to 1200°F (650°C). The alloy is particularly noted for its resistance to post-weld cracking, which is crucial in applications such as aerospace, chemical processing, and power generation.

Key Specifications

- UNS Number: N07718

- Werkstoff Number: 2.4668

- Form: Tubes

- Applications: Aerospace, gas turbines, nuclear reactors, pumps, tooling, and more

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 50.0-55.0 |

| Chromium (Cr) | 17.0-21.0 |

| Iron (Fe) | Bal. (rem.) |

| Molybdenum (Mo) | 2.8-3.3 |

| Niobium (Nb) | 4.75-5.50 |

| Titanium (Ti) | 0.65-1.15 |

| Aluminum (Al) | 0.20-0.80 |

| Cobalt (Co) | ≤ 1.0 |

| Manganese (Mn) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 |

| Carbon (C) | ≤ 0.08 |

| Phosphorus (P) | ≤ 0.015 |

| Sulfur (S) | ≤ 0.015 |

| Boron (B) | ≤ 0.006 |

| Copper (Cu) | ≤ 0.30 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength (min) | 1375 MPa (200 ksi) |

| Yield Strength (0.2% offset) | 1034 MPa (150 ksi) |

| Elongation (min) | 12% |

| Hardness (max) | 330 HB |

| Melting Range | 1260-1340 °C (2300-2440 °F) |

Physical Properties

| Property | Value |

|---|---|

| Density | 8.19 g/cm³ (0.296 lb/in³) |

| Specific Heat Capacity | 435 J/kg·K |

| Thermal Conductivity | 11.4 W/m·K (at 100°C) |

| Electrical Resistivity | 1.25 µΩ·m (at 20°C) |

| Modulus of Elasticity | 211 GPa (30.6 x 10⁶ psi) |

Weight Chart

| Outer Diameter (OD) (mm) | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|

| 12.7 | 1.24 | 0.370 |

| 19.05 | 1.65 | 0.725 |

| 25.4 | 2.11 | 1.320 |

| 38.1 | 2.77 | 2.370 |

| 50.8 | 3.05 | 3.730 |

| 76.2 | 3.40 | 6.570 |

Pressure Rating

Pressure ratings are highly dependent on the specific dimensions and operating conditions. Below are indicative values for common sizes at room temperature:

| Tube Size (OD x Wall) (mm) | Pressure Rating (psi) |

|---|---|

| 12.7 x 1.24 | 3,200 |

| 19.05 x 1.65 | 2,500 |

| 25.4 x 2.11 | 2,000 |

| 38.1 x 2.77 | 1,600 |

| 50.8 x 3.05 | 1,400 |

| 76.2 x 3.40 | 1,200 |

Tolerances

| Dimensions | Tolerance Range |

|---|---|

| Outside Diameter (OD) | ±0.15 mm for OD ≤ 25.4 mm |

| ±0.20 mm for 25.4 mm < OD ≤ 38.1 mm | |

| ±0.30 mm for OD > 38.1 mm | |

| Wall Thickness | ±12% |

| Length | Up to 6.0 m ±6.0 mm |

| Ovality | 2% of OD for thin-wall tubes |

| Straightness | 1/8 inch in any 10-foot length |

Price List

The price of INCONEL alloy 718 steel tubes can vary based on factors such as size, wall thickness, and market conditions. Below is a general price range for some common sizes:

| Size (OD x Wall) (mm) | Price (USD per meter) |

|---|---|

| 12.7 x 1.24 | $100 – $150 |

| 19.05 x 1.65 | $150 – $200 |

| 25.4 x 2.11 | $200 – $250 |

| 38.1 x 2.77 | $250 – $300 |

| 50.8 x 3.05 | $300 – $350 |

| 76.2 x 3.40 | $350 – $400 |

Note: Prices are indicative and can fluctuate based on material costs, supplier, and order quantity.

Types of INCONEL Alloy 718 Tubes

INCONEL alloy 718 tubes can be supplied in various forms to suit specific application needs. These include:

- Seamless Tubes:

- Manufacturing Method: Extrusion or rotary piercing followed by cold drawing.

- Applications: High-pressure and high-temperature environments where superior mechanical properties are required.

- Welded Tubes:

- Manufacturing Method: Forming and welding of flat strips followed by heat treatment.

- Applications: Lower stress applications compared to seamless tubes but still offer excellent corrosion resistance.

- Heat Exchanger Tubes:

- Special Features: High resistance to corrosion and elevated temperatures.

- Applications: Used in heat exchangers for chemical processing, petrochemical, and nuclear power generation.

- Boiler Tubes:

- Special Features: High strength and corrosion resistance at high temperatures.

- Applications: Suitable for use in boilers and superheaters in power plants.

Heat Treatment

INCONEL alloy 718 tubes typically undergo the following heat treatments to achieve desired mechanical properties:

- Solution Annealing:

- Temperature: 1700-1850°F (925-1010°C)

- Purpose: Dissolves secondary phases and provides a homogeneous microstructure.

- Precipitation Hardening:

- Temperature: 1325°F (720°C) for 8 hours, furnace cool to 1150°F (620°C), hold for 8 hours, and air cool.

- Purpose: Enhances strength and hardness through precipitation of gamma prime (γ’) and gamma double prime (γ”) phases.

Applications

Due to its excellent mechanical properties, corrosion resistance, and ability to withstand extreme temperatures, INCONEL alloy 718 is extensively used in:

- Aerospace: Jet engines, rocket motors, spacecraft components

- Chemical Processing: Process equipment, heat exchangers, reactor vessels

- Power Generation: Gas turbines, nuclear reactors, steam generators

- Oil and Gas: Downhole tools, wellhead components, valves

- Marine: Submarine propulsion systems, marine fasteners

Conclusion

INCONEL alloy 718 steel tubes offer a combination of high strength, excellent corrosion resistance, and good fabricability, making them suitable for a wide range of demanding applications. Understanding their chemical composition, mechanical properties, and specific types can help in selecting the right tubes for your specific requirements. Whether for aerospace, power generation, or chemical processing, INCONEL alloy 718 provides reliable performance in challenging environments.