IPN8710 Anticorrosion Steel Pipe

IPN8710 Anticorrosion Steel Pipe

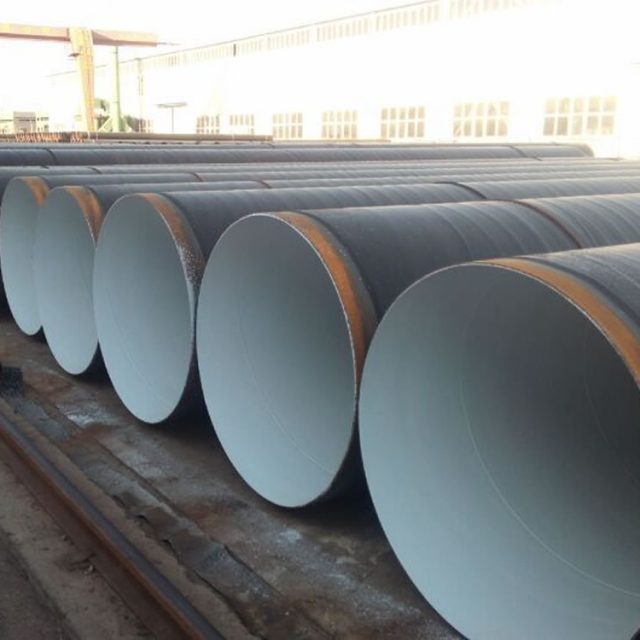

IPN8710 is a type of anticorrosion coating applied to steel pipes to protect them from corrosion, especially in water transport systems. This coating is known for its excellent adhesion, durability, and resistance to various environmental factors. IPN8710 is commonly used in potable water pipelines, sewage systems, and industrial water transport.

Key Specifications

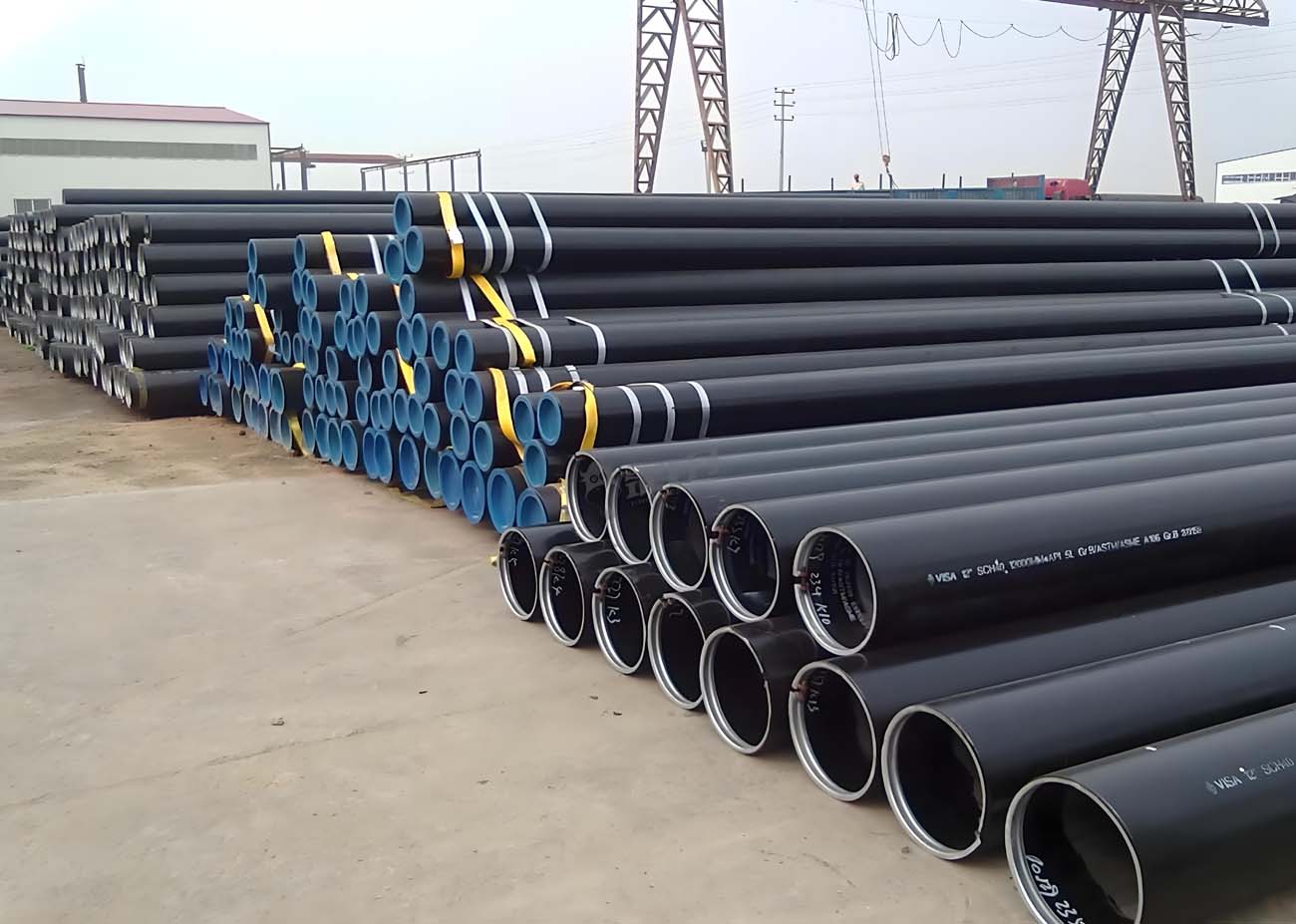

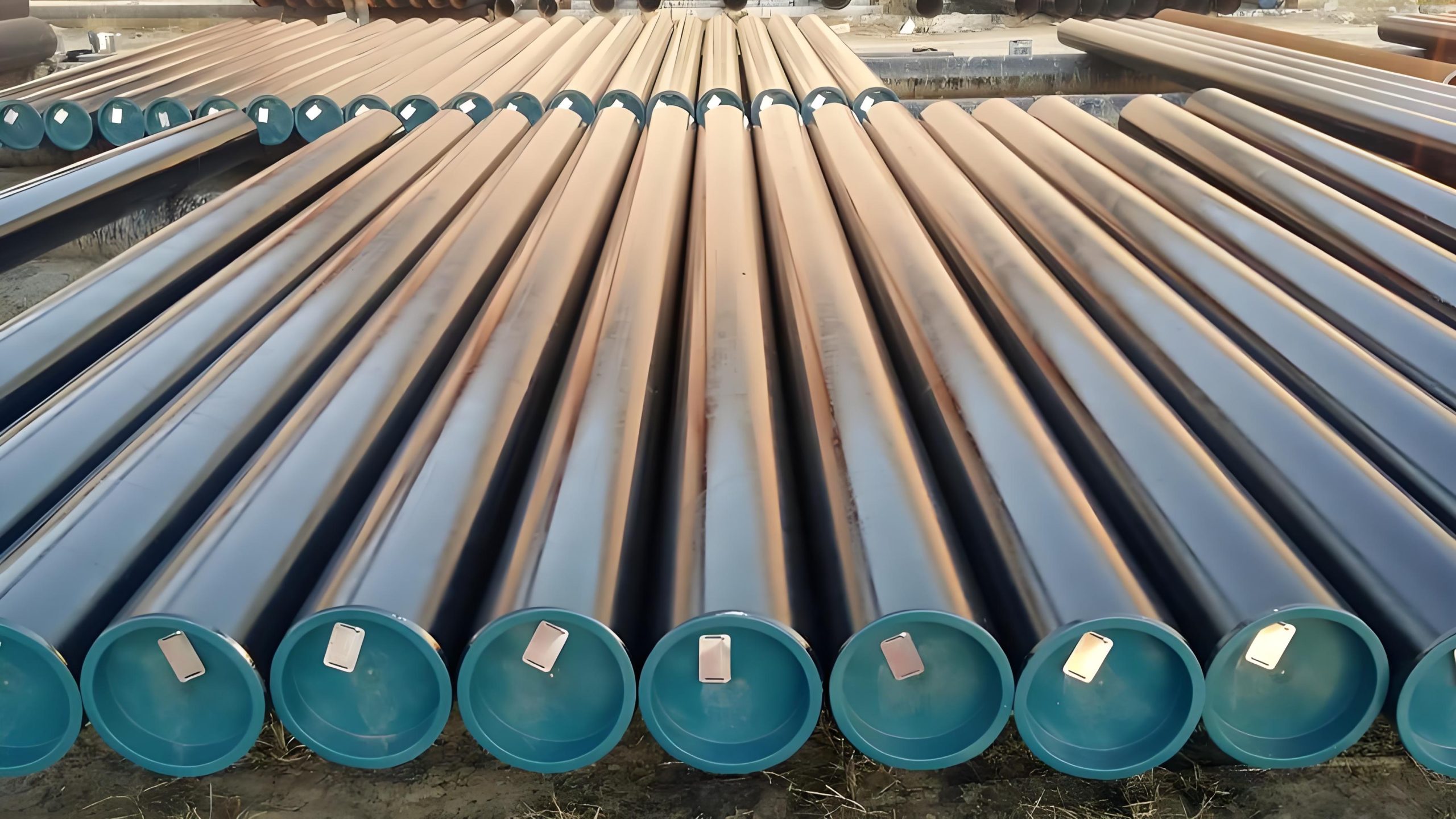

- Material: Carbon Steel, Stainless Steel, Alloy Steel

- Coating Material: IPN8710 Anticorrosion Coating

- Application: Potable water pipelines, sewage systems, industrial water transport

Types Of IPN8710 Anticorrosion Pipes

- Single Layer IPN8710 Coated Pipe:

- Description: A single layer of IPN8710 coating applied to the pipe surface.

- Applications: Suitable for environments with moderate corrosive conditions.

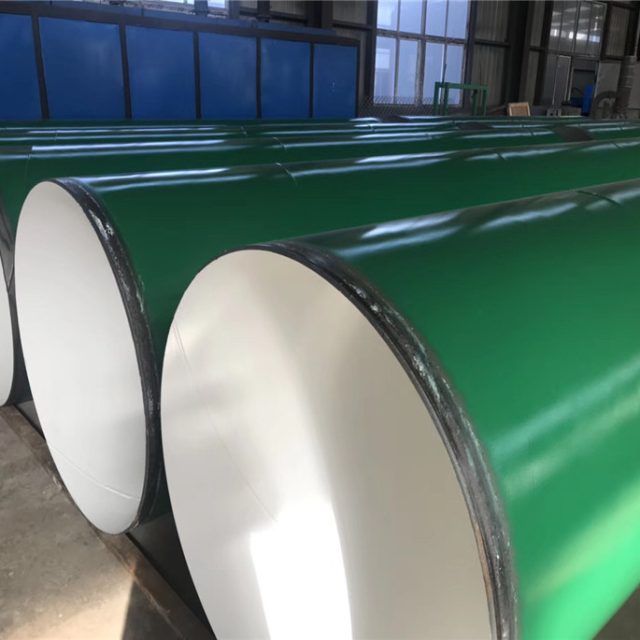

- Double Layer IPN8710 Coated Pipe:

- Description: Two layers of IPN8710 coating for enhanced protection.

- Applications: Used in more aggressive environments requiring additional protection.

Manufacturing Process Of IPN8710 Anticorrosion Pipe

- Pipe Fabrication:

- Steel pipes are manufactured through processes such as electric resistance welding (ERW), submerged arc welding (SAW), or seamless pipe production.

- Surface Preparation:

- The pipe surface is cleaned using abrasive blasting to remove contaminants, rust, and mill scale, ensuring proper adhesion of the IPN8710 coating.

- Coating Application:

- The IPN8710 coating is applied to the prepared pipe surface using a spraying, brushing, or roller method.

- Curing:

- The applied coating is allowed to cure, forming a continuous and uniform protective layer.

IPN8710 Coating Technical Index:

| Item | Index | ||

| Primer panting | Finish panting | ||

| Color | Grey | White | |

| Viscosity(25±1°C)(S) | 60~80 | 60~100 | |

| Fineness(um) | ≤80 | ≤80 | |

| Solids content(%) | >70 | >75 | |

| Drying time

(25±1°C) |

Surface drying(h) | ≤1 | ≤1 |

| Whole drying(h) | ≤24 | ≤24 | |

| Adhesion grades | 1 | 1 | |

| Flexibility(mm) | 1 | 1 | |

| Impact Resistance(cm) | ≥50 | ≥50 | |

| Hardness | ≥0.5 | ≥0.5 | |

| Coating thickness(um) | 40~60 | 40~60 | |

| Usage(kg/m2) | 0.2 | 0.2~0.25 | |

Coating Structure:

| Grades | Structure | Usage (kg/m2) | Dry coating thickness(um) |

| General | Primer – primer – external – external | 0.8 | ≥200 |

| Enhanced | Primer twice– external three times | 1.0 | ≥250 |

The Process Of IPN8710 Coating Application

- Surface Preparation:

- Abrasive blasting to achieve a clean, rough surface, ensuring optimal adhesion of the coating.

- Coating Application:

- The IPN8710 coating is mixed according to manufacturer’s specifications and applied to the pipe surface using spray, brush, or roller techniques.

- Curing:

- The coated pipe is allowed to cure under controlled conditions to ensure the coating forms a hard, durable layer.

Advantages Of IPN8710 Anticorrosion Pipe

- Corrosion Resistance:

- Provides excellent protection against corrosion, particularly in water transport systems.

- Strong Adhesion:

- The IPN8710 coating adheres strongly to the steel surface, ensuring long-lasting protection.

- Durability:

- High resistance to mechanical damage, abrasion, and chemical exposure.

- Safe for Potable Water:

- Suitable for use in potable water pipelines, meeting health and safety standards.

- Ease of Application:

- Can be applied using standard coating techniques, making it versatile and cost-effective.

Performance Of IPN8710 Anticorrosion Pipe

- Corrosion Protection:

- Excellent resistance to moisture, chemicals, and soil conditions, ensuring long-term protection.

- Mechanical Performance:

- High impact and abrasion resistance for durability during transportation, handling, and installation.

- Adhesion:

- Strong adhesion to the pipe surface prevents disbondment and ensures long-term protection.

- Water Safety:

- Safe for use in potable water systems, contributing to safe drinking water supply.

The Service Life Of IPN8710 Anticorrosion Pipe

The service life of IPN8710 anticorrosion pipes can exceed 30-50 years, depending on factors such as:

- Quality of Surface Preparation: Proper surface cleaning and preparation are crucial for optimal adhesion and performance.

- Coating Application Quality: Correct application and curing of the IPN8710 coating are critical for long-term protection.

- Operating Environment: Exposure to harsh chemicals, extreme temperatures, and mechanical stresses can impact the longevity of the coating. However, IPN8710 coatings are designed to withstand a wide range of environmental conditions.

- Maintenance: Regular inspection and maintenance can help identify and address any potential issues early, extending the service life of the pipeline.

Conclusion

IPN8710 anticorrosion steel pipes provide robust protection for pipelines in various environments, particularly in water transport systems. Their excellent corrosion resistance, strong adhesion, and durability make them a reliable choice for ensuring the longevity and integrity of pipelines. Understanding the types, manufacturing process, application steps, and advantages of IPN8710 coated pipes can help in selecting the right product for specific needs, ensuring long-term reliability and efficiency in pipeline systems.

References

- ISO Standards: Specifications for surface preparation and coating application.

- NACE International: Standards and guidelines for corrosion protection and coating applications.

- AWWA (American Water Works Association): Standards for water pipeline materials and coatings.

- anufacturer Technical Data Sheets: Detailed information on specific IPN8710 coating products and application procedures.

-