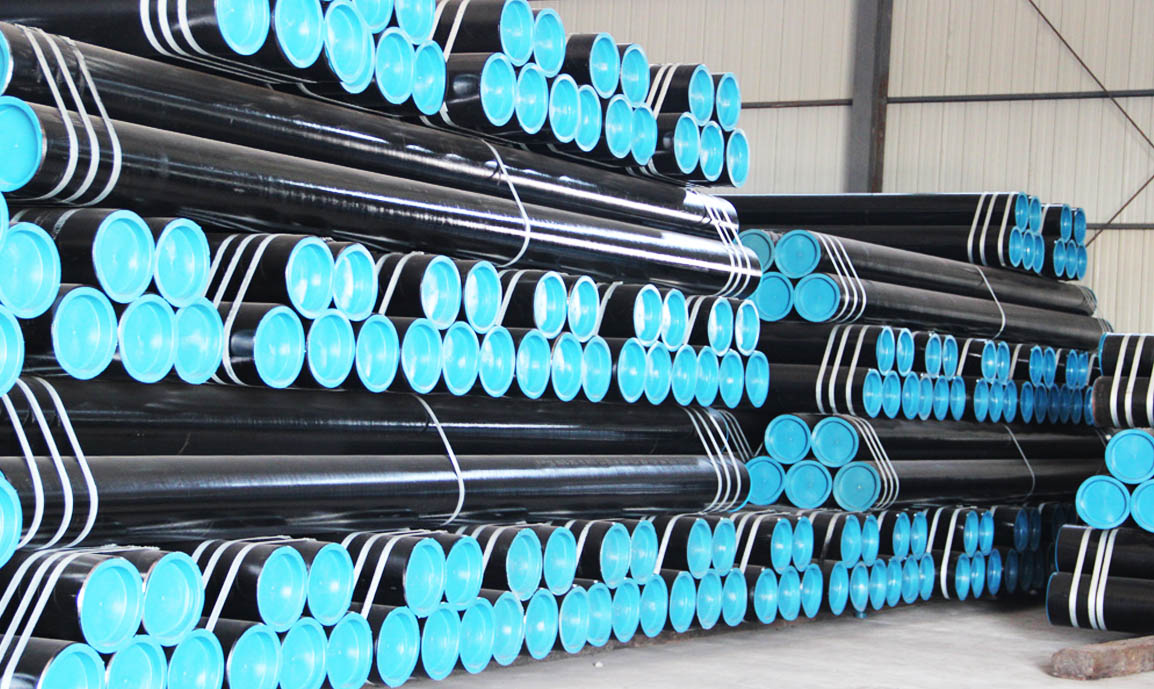

Mechanical Steel Tubes

Mechanical Steel Tubes: An Overview

Mechanical steel tubes are used in a wide variety of applications where precise dimensions, high strength, and durability are required. These tubes are often employed in the manufacture of machinery, automotive components, and structural elements. This guide provides a comprehensive look at mechanical steel tubes, including their characteristics, types, manufacturing processes, materials, standards, applications, and properties.

Characteristics of Mechanical Steel Tubes

- High Strength: Mechanical steel tubes offer excellent tensile and yield strength, making them suitable for high-stress applications.

- Precision: These tubes are manufactured to tight tolerances, ensuring precise dimensions and consistent quality.

- Durability: Mechanical steel tubes are designed to withstand harsh conditions and have a long service life.

- Versatility: Available in various shapes (round, square, rectangular, and custom profiles) to meet diverse application requirements.

- Surface Finish: Can be produced with different surface finishes, such as polished, pickled, or coated, depending on the application needs.

Types of Mechanical Steel Tubes

Mechanical steel tubes can be categorized based on their manufacturing process and the type of steel used:

- Seamless Mechanical Tubes:

- Produced without a welded seam, offering uniform structure and strength.

- Ideal for applications requiring high precision and strength.

- Welded Mechanical Tubes:

- Made by welding the edges of a steel strip or plate.

- Suitable for less demanding applications where cost is a significant factor.

Manufacturing Process

Seamless Mechanical Tubes

- Billet Preparation: A solid cylindrical billet is heated to a high temperature.

- Piercing: The heated billet is pierced to create a hollow tube.

- Elongation: The hollow tube is elongated and rolled to the desired thickness and diameter.

- Sizing and Shaping: The tube is passed through sizing rolls to achieve precise dimensions and desired shape.

- Cooling: The tube is cooled in a controlled manner to maintain material properties.

- Finishing: The tube undergoes various finishing processes, such as cutting, straightening, and surface treatment.

Welded Mechanical Tubes

- Steel Strip Preparation: A flat steel strip is prepared and cleaned.

- Forming: The strip is formed into a tubular shape using rollers.

- Welding: The edges of the formed tube are welded together (ERW or other welding methods).

- Sizing and Shaping: The welded tube is passed through sizing rolls to achieve precise dimensions and desired shape.

- Cooling: The tube is cooled to set the weld and maintain material properties.

- Finishing: The tube undergoes various finishing processes, such as cutting, straightening, and surface treatment.

Materials

Mechanical steel tubes are made from various types of steel to suit different applications:

- Carbon Steel: Commonly used for general-purpose applications due to its strength and affordability. Examples include ASTM A519 and SAE 1020.

- Alloy Steel: Provides enhanced mechanical properties, such as increased strength and toughness. Examples include ASTM A335 and 4140/42 CrMo.

- Stainless Steel: Known for its excellent corrosion resistance and durability. Examples include ASTM A554 and A312.

- High-Strength Low-Alloy Steel (HSLA): Offers high strength and toughness with good weldability.

Standards

Mechanical steel tubes must comply with various standards to ensure quality and performance. Some key standards include:

- ASTM Standards:

- ASTM A519: Standard specification for seamless carbon and alloy steel mechanical tubing.

- ASTM A513: Standard specification for electric-resistance-welded carbon and alloy steel mechanical tubing.

- ASTM A554: Standard specification for welded stainless steel mechanical tubing.

- SAE Standards:

- SAE J524: Seamless low-carbon steel tubing suitable for bending, flaring, forming, and brazing.

- SAE J525: Welded and cold drawn low-carbon steel tubing suitable for bending, flaring, forming, and brazing.

- DIN Standards:

- DIN 2391: Precision seamless tubes.

- DIN 2448: Seamless steel tubes for mechanical and general engineering purposes.

Applications

Mechanical steel tubes are used in numerous industries due to their strength, precision, and versatility:

- Automotive: Drive shafts, steering columns, exhaust systems, and roll cages.

- Machinery: Hydraulic cylinders, structural components, and machine parts.

- Construction: Structural supports, scaffolding, and framework.

- Aerospace: Structural elements, hydraulic systems, and landing gear components.

- Furniture: Frames, supports, and aesthetic elements.