Interpret and exceed complex technical specifications Maintain rigorous quality control across global supply chains Deliver mission-critical components on accelerated timelines Provide ongoing technical support throughout product lifecycle

admin

Ringkasnya, Aloi 602 Ca (2.4633, N06025) represents a pinnacle of materials engineering, blending exceptional properties with practical utility. Its standards ensure quality, its composition delivers performance, and its applications span critical industries. Whether in a chemical reactor, a power plant furnace, or a diesel engine, Aloi 602 CA proves its worth as a material built for the toughest challenges.

Incoloy 28 (AS N08028 / W. Nr. 1.4563) alloy steel pipe stands out as a premier material for industries requiring exceptional corrosion resistance and mechanical strength. Its carefully engineered composition, adherence to stringent standards, and versatility in dimensions and forms make it a reliable choice for critical applications. The detailed tables provided—covering parameters, dimensi, ujian, penilaian tekanan, komposisi kimia, and mechanical properties—offer a comprehensive resource for understanding and specifying this alloy. Whether used in chemical plants, oilfields, or marine systems, Incoloy 28 delivers unparalleled performance, ensuring safety and efficiency in the most demanding environments.

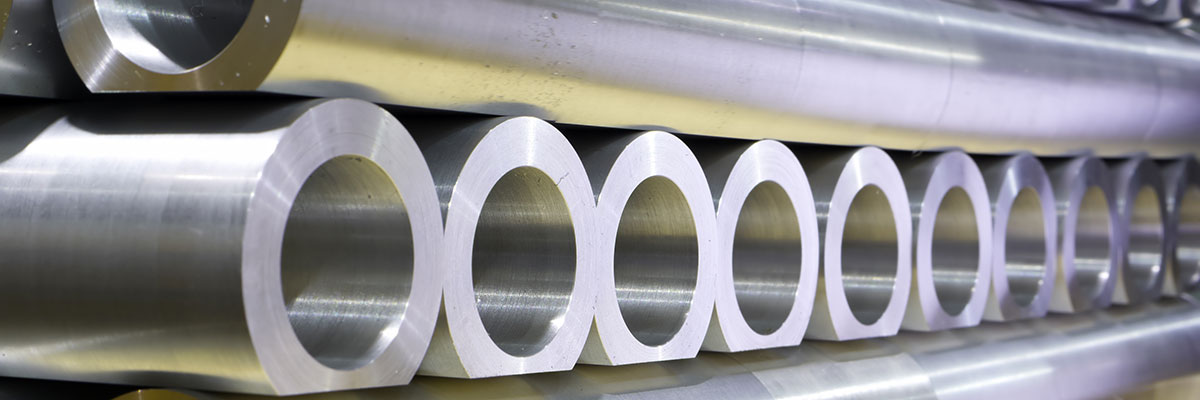

Large-diameter thick-walled seamless steel pipes, produced through advanced processes like hot piercing and heat treatment, offer exceptional strength and reliability. International grades from EN (cth., 34CrMo4) and ASTM (cth., A519 4140) alongside GB standards meet diverse needs, from hydraulic cylinders to energy infrastructure, ensuring performance under high pressure and stress.

For high-pressure hydraulic cylinders, seamless steel pipes such as ST52 (E355), SAE 4140 (42CrMo), 37Mn, and 34CrMo4 are widely used, adhering to standards like DIN 2391, ASTM A519, and GB 18248. These grades offer the necessary strength, keliatan, and precision to ensure safety and performance under extreme pressures. Selection depends on specific pressure requirements, keadaan alam sekitar, and manufacturing processes like honing or heat treatment.

The welding of UNS N08825 pipelines demands a holistic approach integrating material science, process engineering, and stringent quality control. By optimizing TIG/MIG/SMAW parameters, mitigating defects through pre/post-weld treatments, and adhering to international standards, industries can leverage the alloy’s full potential in corrosive and high-temperature environments. Continuous advancements in welding technologies promise enhanced efficiency and reliability for future applications.

Welding Inconel 625 and P22 requires meticulous control of thermal gradients, filler selection, and post-weld treatments to address metallurgical incompatibilities. Industry standards and advanced processes (cth., EMB, kimpalan laser) enhance joint reliability in critical applications. Continuous innovation in welding technology will further optimize these dissimilar joints for extreme environments.

2205 flange kimpalan rata plat keluli dupleks (HG/T 20592 DN40 PN10 PLRF) Menggabungkan rintangan kakisan bahan dengan kelebihan ringan struktur, dan sesuai untuk persekitaran yang menghakis tekanan sederhana dan rendah seperti industri kimia dan kejuruteraan marin. Reka bentuknya mesti mengikut saiz dan spesifikasi tekanan Hg/t 20592, dan perhatikan proses kimpalan dan penyelenggaraan semasa pemprosesan dan penggunaan untuk memastikan kebolehpercayaan jangka panjang.

Monel K-500 is a high-performance nickel-copper-based alloy with excellent corrosion resistance and mechanical properties, suitable for a variety of industrial applications. Its good welding properties and processability make it have high flexibility in the manufacturing process. Through appropriate heat treatment processes, its performance can be further improved and the needs of different working conditions can be met.

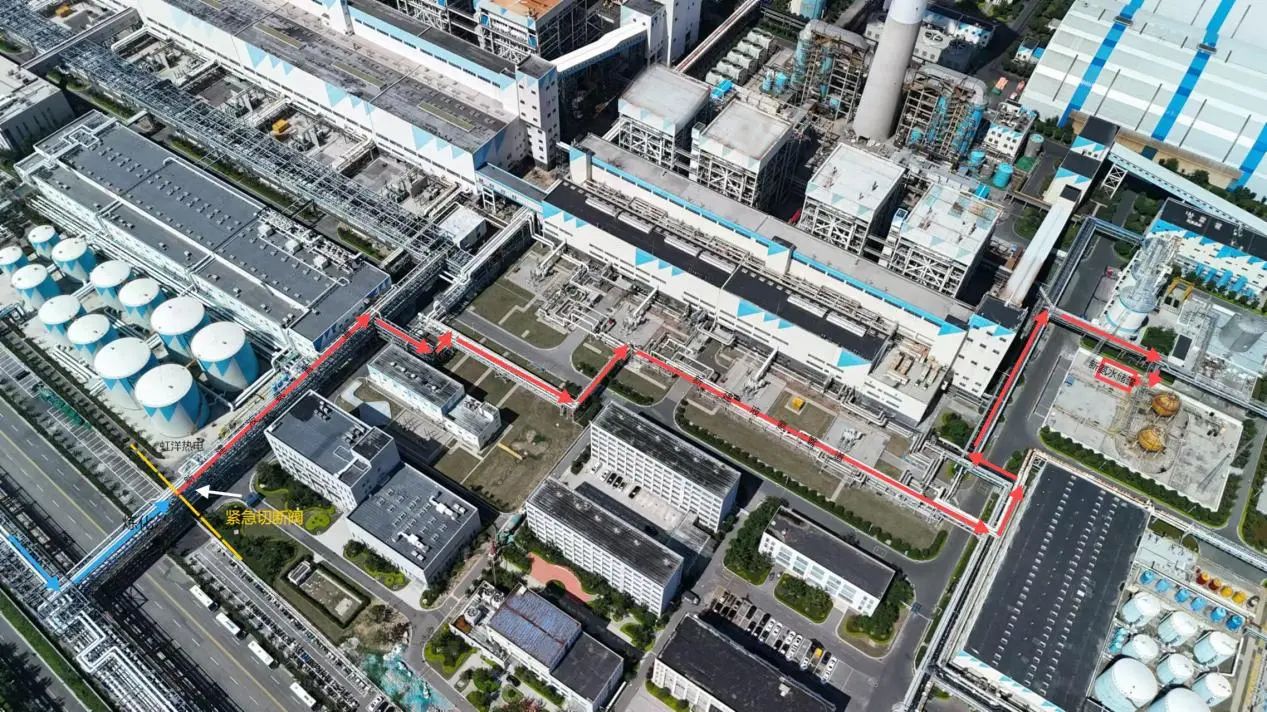

Melalui amalan kimpalan lebih daripada 400 Pelabuhan Dyne di bahagian gasifikasi peranti sintesis ammonia kimia liuguo, ditunjukkan bahawa proses kimpalan di atas dapat memastikan kualiti kimpalan. Berdasarkan hasil kadar lulus 96%, ia mencukupi. Buktikan ini.