The choice between Inconel® X-750 (AS N07750) dan Aloi Nikel 600 depends largely on the specific requirements of the application: Choose Inconel X-750 for high-stress, high-temperature applications where mechanical strength, fatigue resistance, and creep resistance are critical (cth., aeroangkasa, nuklear, and gas turbines). Choose Nickel Alloy 600 for versatile corrosion resistance in general-purpose applications or where fabrication and cost-efficiency are more important (cth., pemprosesan kimia, marin, dan penukar haba).

Blog

Hastelloy C276 alloy steel pipes, produced under ASTM B622 UNS N10276 standards, are indispensable in industries that demand high corrosion resistance and durability. With its exceptional properties, wide-ranging applications, and long lifespan, this material remains a top choice for critical applications. Investing in Hastelloy C276 ensures reliability and performance, even in the most challenging environments.

Hastelloy C-276 stands out as one of the most versatile and corrosion-resistant alloys available today. Its unique properties make it indispensable in industries where performance and reliability are paramount. From resisting aggressive acids in chemical plants to enduring the harsh conditions of marine environments, Hastelloy C-276 has proven its worth time and again. While its high cost and fabrication challenges may pose limitations, the benefits it offers far outweigh these drawbacks for critical applications.As global industries continue to push the boundaries of innovation, Hastelloy C-276 will remain a cornerstone material for demanding environments, memastikan keselamatan, kecekapan, and durability for years to come.

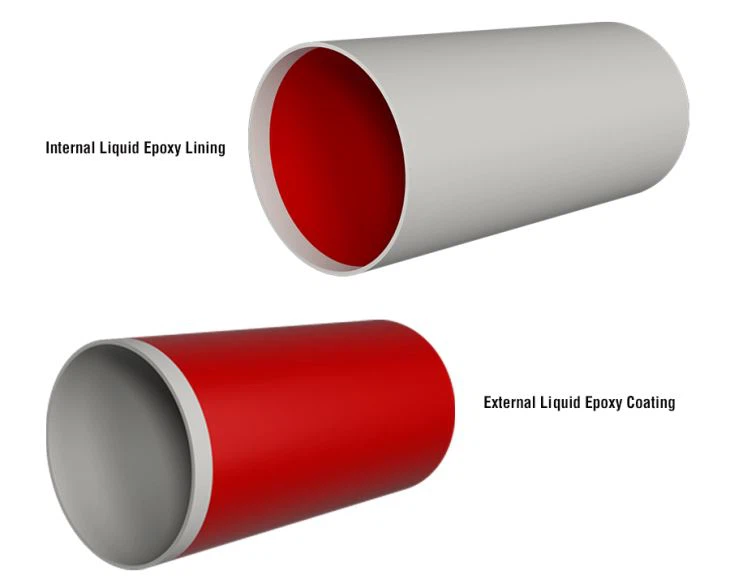

Liquid-epoxy coatings and linings are essential for protecting steel water pipes and fittings in water infrastructure systems. From their superior corrosion resistance to their adaptability for various applications, these coatings ensure the long-term performance and safety of pipelines. By adhering to proper application techniques, protokol pemeriksaan, and industry standards, project managers and engineers can maximize the benefits of epoxy coatings. Whether you're working on a potable water system or a wastewater project, liquid-epoxy coatings provide a durable, kos efektif, and environmentally friendly solution to meet the demands of modern water infrastructure.

Epoxy-coated steel pipes are essential for ensuring the durability, keselamatan, and efficiency of water supply, saliran, and dredging systems. By complying with international standards and offering superior corrosion resistance, epoxy-coated pipes deliver exceptional performance in harsh operating conditions.

Dupleks 2205 (AS S32205) steel pipe is a high-performance material that offers a blend of strength, rintangan kakisan, dan ketahanan. Ideal for use in challenging environments like oil and gas, marine applications, dan pemprosesan kimia, it outperforms standard austenitic steels in many areas. Namun begitu, its higher cost and welding challenges may make it less ideal for less demanding applications.

The CFD analysis of water flow inside buttweld elbow pipes reveals that the normal-edged elbow pipe outperforms the sharp-edged elbow pipe in terms of flow efficiency, penggunaan tenaga, dan integriti struktur. Penemuan utama termasuk:

ASTM A210 Grade A1 Seamless Tube shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. The offered ASTM A210 GR A1 CS Seamless Tubes is availed in diverse sizes and other related specifications, to meet requirements of our prominent clients.ASME SA 210 Gr.A1 Boiler Pipes that is designed according to set industry standards. As per the needs and requirements of our clients, we are involved in providing ASME SA 210 Gr. A1 Boiler Tubes. Buy ASTM A210 Grade A1 Boiler Tubes at reasonable cost from us.

When selecting between seamless and welded high nickel alloy pipes, consider factors such as pressure requirements, rintangan kakisan, cost, and size availability to ensure that you choose the right type of pipe for your project. For more information or assistance in selecting the right pipe, consult with a materials specialist or supplier who can help guide you through the decision-making process.

Both 3LPP and 3PE coatings provide excellent protection for steel pipelines, but they are designed for different operating conditions. 3LPP coatings, with their high-temperature resistance and superior mechanical strength, are ideal for pipelines in harsh environments or those transporting hot fluids. On the other hand, 3Salutan PE, with their cost-effectiveness and good flexibility, are better suited for pipelines in moderate environments where temperature and mechanical stress are lower.