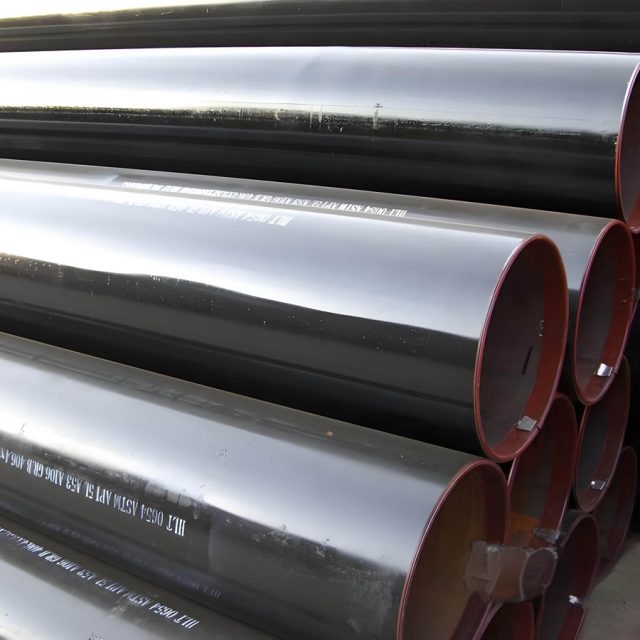

Paip Keluli ERW

Paip Keluli ERW

ERW (Rintangan Elektrik Dikimpal) paip keluli are a type of steel pipe that are manufactured through a welding process that employs electric resistance. ERW pipes are used in various applications due to their high quality, ketahanan, dan keberkesanan kos. Here’s an overview of ERW steel pipes, their manufacturing process, aplikasi, dan faedah.

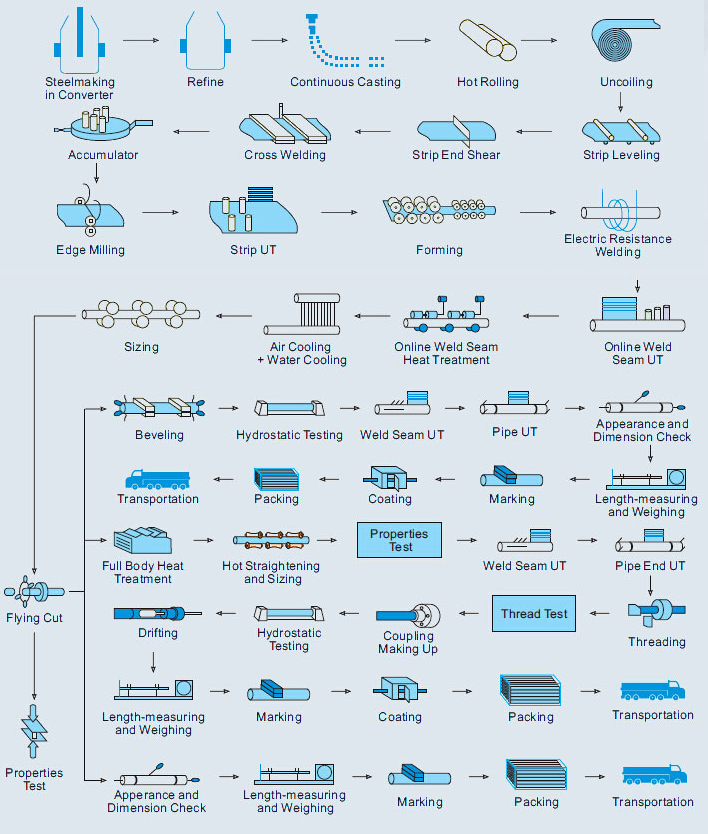

Proses Pengilangan

- Raw Material:

- The manufacturing process begins with coils of steel, which are cut into strips of appropriate width.

- Membentuk:

- The steel strips are passed through a series of rollers to form them into a cylindrical shape.

- Kimpalan:

- The edges of the cylindrical steel strip are heated and pressed together using electric resistance welding, forming a continuous seam. Unlike other welding methods, no filler material is used.

- Penamat:

- The welded seam is then annealed (heat-treated) to remove any residual stresses from the welding process.

- The pipe is then cut to the desired length, and further finishing processes like straightening, end-facing, and coating may be applied.

- Kawalan Kualiti:

- ERW pipes undergo various quality control tests, including ultrasonic testing, hydrostatic testing, and visual inspection to ensure they meet industry standards and specifications.

Diameter Luar

- Julat: 1/2″ ke 28″

Ketebalan Dinding

- Julat: 1.65 mm ke 20 mm (Semua Jadual)

Panjang

- Julat: 1 m ke 12 m atau mengikut keperluan pelanggan

Piawaian

- ASTM 5L

- ASTM A53

- ASTM A178

- ASTM A500/501

- ASTM A691

- ASTM A252

- ASTM A672

- DALAM 10217

Gred Bahan

- API 5L: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

- ASTM A53: GR.A, GR.B

- DALAM: S275, S275JR, S355JRH, S355J2H

Paip Berakhir

- Hujung Biasa

- Hujung Serong

- Berbenang

Pilihan Rawatan Permukaan

- telanjang

- Dicat Hitam

- Bervarnis

- Bergalvani

- Salutan anti-karat (3PE, PP/EP, Salutan FBE, dll.)

Proses Pengilangan

- Dilukis Sejuk

- Digulung Panas

Pengujian dan Jaminan Kualiti

- Analisis Komponen Kimia

- Sifat Mekanikal:

- Kekuatan tegangan muktamad

- Kekuatan hasil

- Pemanjangan

- Sifat Teknikal:

- Ujian Meratakan

- Ujian Lenturan

- Ujian Kekerasan

- Ujian Kesan

- Pemeriksaan Saiz Luaran

- Ujian Hidrostatik

- Ujian Tidak Memusnahkan (NDT):

- ET (Ujian Semasa Eddy)

- RT (Ujian Radiografi)

- UT (Ujian Ultrasonik)

Spesifikasi

Spesifikasi:

|

INCH

|

DARIPADA

(MM)

|

Strandard Wall Thickness

|

|||||||

|

SCH 10WT

(mm)

|

SCH 20WT

(mm)

|

SCH 40WT

(mm)

|

SCH 60WT

(mm)

|

SCH 80WT (mm) |

SCH 100WT (mm) |

SCH 160WT (mm) |

XXS (mm) |

||

|

1/4”

|

13.7

|

|

|

2.24

|

|

3.02

|

|

|

|

|

3/8”

|

17.1

|

|

|

2.31

|

|

3.2

|

|

|

|

|

1/2”

|

21.3

|

2.11

|

|

2.77

|

|

3.73

|

|

4.78

|

7.47

|

|

3/4″

|

26.7

|

2.11

|

|

2.87

|

|

3.91

|

|

5.56

|

7.82

|

|

1″

|

33.4

|

2.77

|

|

3.38

|

|

4.55

|

|

6.35

|

9.09

|

|

1-1/4″

|

42.2

|

2.77

|

|

3.56

|

|

4.85

|

|

6.35

|

9.7

|

|

1-1/2″

|

48.3

|

2.77

|

|

3.68

|

|

5.08

|

|

7.14

|

10.15

|

|

2″

|

60.3

|

2.77

|

|

3.91

|

|

5.54

|

|

8.74

|

11.07

|

|

2-1/2″

|

73

|

3.05

|

|

5.16

|

|

7.01

|

|

9.53

|

14.02

|

|

3″

|

88.9

|

3.05

|

|

5.49

|

|

7.62

|

|

11.13

|

15.24

|

|

3-1/2″

|

101.6

|

3.05

|

|

5.74

|

|

8.08

|

|

|

|

|

4″

|

114.3

|

3.05

|

4.5

|

6.02

|

|

8.56

|

|

13.49

|

17.12

|

|

5″

|

141.3

|

3.4

|

|

6.55

|

|

9.53

|

|

15.88

|

19.05

|

|

6″

|

168.3

|

3.4

|

|

7.11

|

|

10.97

|

|

18.26

|

21.95

|

|

8″

|

219.1

|

3.76

|

6.35

|

8.18

|

10.31

|

12.7

|

15.09

|

23.01

|

22.23

|

|

10″

|

273

|

4.19

|

6.35

|

9.27

|

12.7

|

15.09

|

18.26

|

28.58

|

25.4

|

|

12″

|

323.8

|

4.57

|

6.35

|

10.31

|

14.27

|

17.48

|

21.44

|

33.32

|

25.4

|

|

14″

|

355

|

6.35

|

7.92

|

11.13

|

15.09

|

19.05

|

23.83

|

36.71

|

|

|

16″

|

406

|

6.35

|

7.92

|

12.7

|

16.66

|

21.44

|

26.19

|

40.49

|

|

|

18″

|

457

|

6.35

|

7.92

|

14.27

|

19.05

|

23.83

|

29.36

|

46.24

|

|

|

20″

|

508

|

6.35

|

9.53

|

15.09

|

20.62

|

26.19

|

32.54

|

50.01

|

|

|

22″

|

559

|

6.35

|

9.53

|

|

22.23

|

28.58

|

34.93

|

54.98

|

|

|

24″

|

610

|

6.35

|

9.53

|

17.48

|

24.61

|

30.96

|

38.89

|

59.54

|

|

|

26″

|

660

|

7.92

|

12.7

|

|

|

|

|

|

|

|

28″

|

711

|

7.92

|

12.7

|

|

|

|

|

|

|

|

30″

|

762

|

7.92

|

12.7

|

|

|

|

|

|

|

|

32″

|

813

|

7.92

|

12.7

|

17.48

|

|

|

|

|

|

|

34″

|

863

|

7.92

|

12.7

|

17.48

|

|

|

|

|

|

|

36″

|

914

|

7.92

|

12.7

|

19.05

|

|

|

|

|

|

|

38″

|

965

|

|

|

|

|

|

|

|

|

|

40″

|

1016

|

|

|

|

|

|

|

|

|

|

42″

|

1066

|

|

|

|

|

|

|

|

|

|

44″

|

1117

|

|

|

|

|

|

|

|

|

|

46″

|

1168

|

|

|

|

|

|

|

|

|

|

48″

|

1219

|

|

|

|

|

|

|

|

|

Standard

Analisis Kimia dan Sifat Mekanikal

| Standard | Kelas | Gred | Analisis Kimia(%) | Sifat Mekanikal(min)(Mpa) | ||||

| C | Mn | P | S | Kekuatan Tegangan | Kekuatan Hasil | |||

| API 5L | PSL1 | B | 0.26 | 1.20 | 0.030 | 0.030 | 414 | 241 |

| X42 | 0.26 | 1.30 | 0.030 | 0.030 | 414 | 290 | ||

| X46 | 0.26 | 1.40 | 0.030 | 0.030 | 434 | 317 | ||

| X52 | 0.26 | 1.40 | 0.030 | 0.030 | 455 | 359 | ||

| X56 | 0.26 | 1.40 | 0.030 | 0.030 | 490 | 386 | ||

| X60 | 0.26 | 1.40 | 0.030 | 0.030 | 517 | 414 | ||

| X65 | 0.26 | 1.45 | 0.030 | 0.030 | 531 | 448 | ||

| X70 | 0.26 | 1.65 | 0.030 | 0.030 | 565 | 483 | ||

| PSL2 | B | 0.22 | 1.20 | 0.025 | 0.015 | 414 | 241 | |

| X42 | 0.22 | 1.30 | 0.025 | 0.015 | 414 | 290 | ||

| X46 | 0.22 | 1.40 | 0.025 | 0.015 | 434 | 317 | ||

| X52 | 0.22 | 1.40 | 0.025 | 0.015 | 455 | 359 | ||

| X56 | 0.22 | 1.40 | 0.025 | 0.015 | 490 | 386 | ||

| X60 | 0.22 | 1.40 | 0.025 | 0.015 | 517 | 414 | ||

| X65 | 0.22 | 1.45 | 0.025 | 0.015 | 531 | 448 | ||

| X70 | 0.22 | 1.65 | 0.025 | 0.015 | 565 | 483 | ||

| X80 | 0.22 | 1.85 | 0.025 | 0.015 | 621 | 552 | ||

Proses

Aplikasi

ERW steel pipes are used in a wide range of applications due to their versatility and cost-efficiency:

- Industri Minyak dan Gas: Transportation of oil, gas, dan cecair lain.

- Sistem Bekalan Air: Pipes for potable water and sewage systems.

- Industri Automotif: Komponen struktur, exhaust systems, and other automotive parts.

- Pembinaan: Structural applications in buildings, jambatan, dan projek infrastruktur lain.

- Kejuruteraan Mekanikal dan Am: Fabrication of mechanical parts and general engineering components.

Faedah

- Kos-Efektif: ERW pipes are generally less expensive than seamless pipes.

- High Quality: The manufacturing process ensures a high degree of dimensional accuracy and uniformity.

- Kekuatan dan Ketahanan: ERW pipes have good mechanical properties and are suitable for high-pressure applications.

- serba boleh: Available in various sizes, ketebalan, and lengths, making them suitable for diverse applications.

- Kecekapan: The ERW process is efficient, allowing for mass production with consistent quality.

Types of ERW Pipes

- Round ERW Pipes: Commonly used in fluid transportation.

- Square and Rectangular ERW Pipes: Often used in structural applications.

- Galvanized ERW Pipes: Coated with zinc to prevent corrosion, used in outdoor and harsh environments.

Piawaian dan Spesifikasi

ERW steel pipes are manufactured to meet various international standards and specifications, termasuk:

- API 5L: Specification for line pipes.

- ASTM A53: Spesifikasi standard untuk paip, keluli, hitam dan celup panas, bersalut zink, dikimpal dan lancar.

- ASTM A252: Standard specification for welded and seamless steel pipe piles.

- BS 1387: Spesifikasi untuk tiub keluli berskru dan bersoket dan tiub dan untuk tiub keluli hujung biasa sesuai untuk kimpalan atau untuk skru ke BS 21 benang paip.

Kesimpulan

ERW steel pipes are an essential component in various industries due to their reliability, keberkesanan kos, dan serba boleh. Their manufacturing process ensures a high-quality product that meets stringent industry standards, making them a preferred choice for many applications.