Kesan suhu pembajaan pada mikrostruktur dan sifat keluli selongsong minyak yang digunakan untuk telaga dalam

Kesan suhu pembajaan pada mikrostruktur dan sifat keluli selongsong minyak yang digunakan untuk telaga dalam

Authors: Wang Jiaojiao, Zhao Linlin, Gao Yunzhe, Shi Shuai, Wu Xiaolong, Zhao Yanqing, Zhou Yuqing, Gong Junjie

(Hebei Dahe Materials Technology Co., Ltd., Shijiazhuang, Hebei 050023)

Abstract: The influence of tempering temperature after quenching at 920°C on the microstructure and mechanical properties of a deep well oil casing steel was studied by means of optical microscopy (OM), scanning electron microscopy (SEM), and tensile testing machines. The results show that the tested steel tempered at 500-600°C obtains tempered sorbite, exhibiting high strength, plasticity, dan ketangguhan, with a product of strength and elongation ranging from 20.5 kepada 22.1 GPa·% and impact absorbed energy ranging from 94.6 kepada 100.3 J. When the tempering temperature is 550°C, the tested steel for deep well oil casing exhibits the best comprehensive mechanical properties, with tensile strength of 978 MPa, yield strength of 935 MPa, product of strength and elongation of 22.1 GPa·%, and impact absorbed energy of 100.3 J.

Kata kunci: Oil casing steel; Tempering temperature; Microstructure; Sifat mekanikal

1. pengenalan

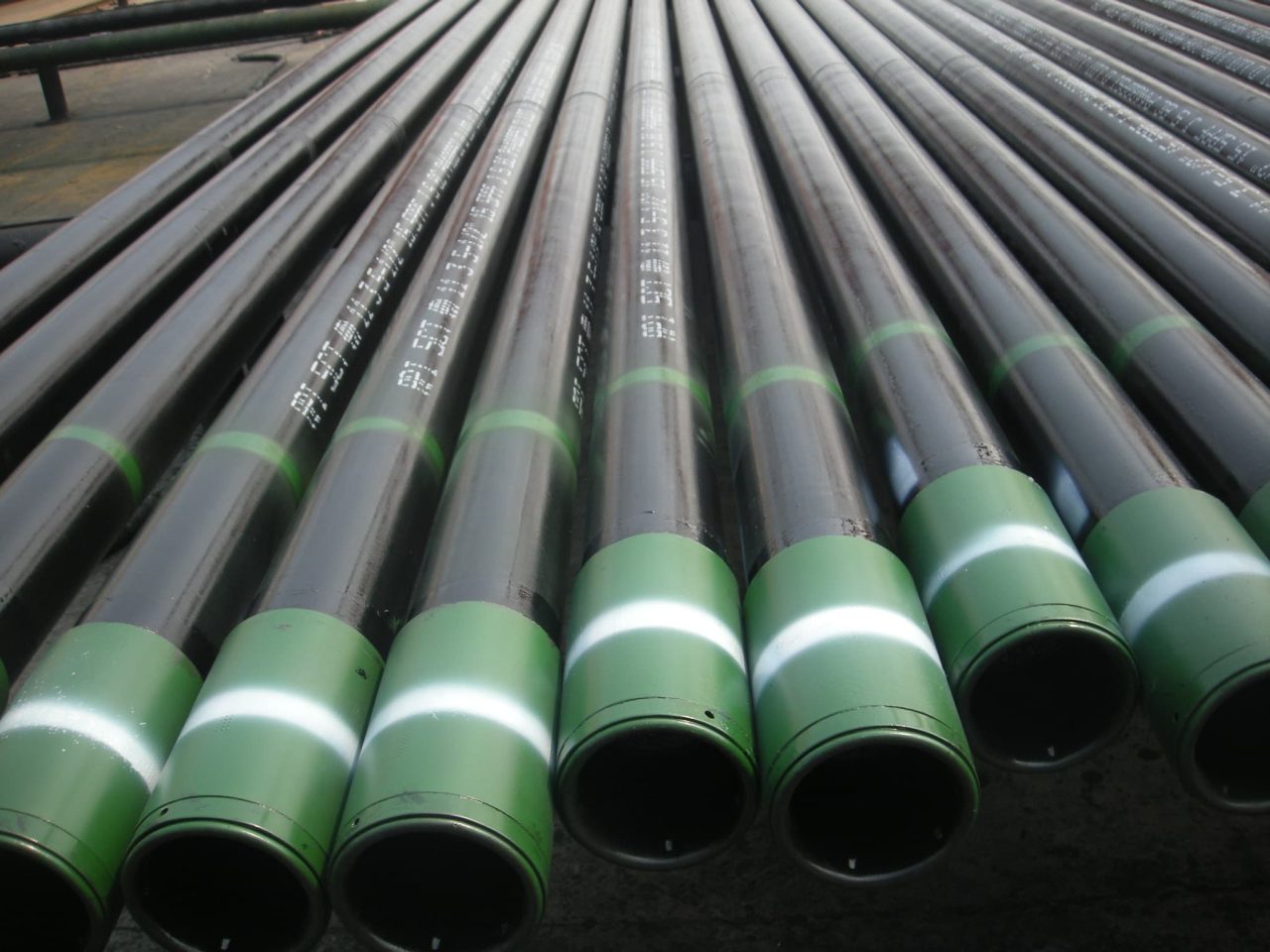

With the increasing global competition for strategic energy resources, oil and gas resources have attracted considerable attention. Their reserve capacity and extraction levels are of great significance to the modernization of society 1-2]. Due to continuous exploitation of oil and gas energy resources for over a century, the reserves of easily exploitable oil and gas energy resources on the Earth’s surface have been unable to meet human demand, leading to an increasing proportion of the exploitation of deep and ultra-deep well oil and gas energy resources -4]. According to statistics, in recent years, the depth of oil and gas wells globally has continued to grow rapidly, with the depth of deep wells exceeding 5000 m, nearly doubled compared to before. The service environment of oil and gas casings is complex and harsh, and with the continuous increase in the depth of oil and gas wells, to ensure safety, the casings used are required to have high strength, high plasticity, and high impact performance 5-6].

2. Experimental Materials and Methods

The tested steel used in this paper was smelted in a 50 kg vacuum furnace and cast into a steel billet with the following chemical composition (mass fraction, %): 0.22C, 0.20Dan, 1.35Mn, 0.28Cr, 0.17Mo, 0.18V, balance Fe. The smelted steel billet was heated to 1250°C and held for 120 min in a heat-preserving furnace, then rolled into a 15 mm thick hot-rolled slab with an initial rolling temperature above 1150°C and a final rolling temperature above 850°C. It was then cooled to room temperature by sand burial. Metallographic, kesan, and tensile specimen blanks were cut from the hot-rolled slab, heated to 920°C and held for 40 min in an electric resistance heating furnace, then water-quenched to room temperature. Subsequently, they were heated to 500°C, 550°C, and 600°C and held for 60 min, followed by air cooling to room temperature.

3. Experimental Results and Discussion

3.1 Effect of Tempering Temperature on Microstructure

The OM and SEM images of the tested steel after water quenching and tempering at different temperatures are shown in Figure 1. It can be seen that the water-quenched microstructure is typical lath martensite, with clearly visible prior austenite grain boundaries (PAGB) and lath boundaries, and a uniform structure. After tempering at different temperatures, tempered sorbite is obtained. After tempering at 500°C, the tested steel still retains the lath structure of the quenched martensite, with clear PAGB accompanied by film-like carbide precipitation, and short rod-like carbides mostly distributed at the lath boundaries and on the laths. After tempering at 550°C, the PAGB of the tested steel begins to blur, accompanied by the precipitation of short rod-like carbides, and the carbide precipitation begins to spheroidize. After tempering at 600°C, the PAGB of the tested steel further blurs, and no obvious lath boundaries can be observed. The carbides become more spheroidized and finer. With the increase in tempering temperature, the degree of recovery and recrystallization of the tested steel continuously increases, the PAGB and lath boundaries gradually blur, the carbide precipitation gradually spheroidizes, and the carbide size gradually decreases. It is worth noting that the microstructural size of the tested steel does not change significantly with the increase in tempering temperature, which is attributed to the addition of Mo element in the tested steel. Previous studies have shown that the Mo element has the effects of solid solution strengthening, increasing toughness, and enhancing tempering stability -8]. The tested steel also contains the V element, which has a precipitation strengthening effect ]. In previous studies, it has been found that the fine and dispersed carbide precipitation is alloy cementite (M3C), secondary hardened carbide (V,X)C, and undissolved carbide (V,X)C during austenitization, where M = Fe, Cr, Mn; X = Mo, Cr 10-12]. Moreover, the coherent dispersion precipitation of the second phase formed by trace elements such as Mo and V pins dislocations, improving the mechanical properties of the tested steel. The secondary precipitation hardening peak temperatures of Mo and V elements are in the ranges of 570-580°C and 600-625°C, masing -masing 13].

3.2 Effect of Tempering Temperature on Mechanical Properties

The mechanical properties of the tested steel at different tempering temperatures are shown in Figure 2. As can be seen from Figure 2(a), both the tensile strength and yield strength gradually decrease with the increase in tempering temperature. This is because during tempering, the quenched high-carbon martensite structure undergoes recovery, and the dislocations undergo slip reorganization and mutual cancellation, i.e., the dislocation density decreases, both of which soften the microstructure 4-15]. Notably, the tensile strength ranges from 961 kepada 1023 MPa, and the yield strength ranges from 928 kepada 992 MPa, indicating a small range of strength changes. During tempering, fine and dispersed carbides continuously precipitate, producing a strengthening effect. The strengthening and softening effects offset each other, resulting in a small fluctuation range of strength, which corresponds to the tempered microstructure. With the increase in tempering temperature, the product of strength and elongation and impact absorbed energy of the tested steel both exhibit a trend of first increasing and then decreasing, as shown in Figure 2(b, c). The product of strength and elongation ranges from 20.5 kepada 22.1 GPa·%, and the impact absorbed energy ranges from 94.6 kepada 100.3 J. That is, the tested steel exhibits high strength, plasticity, and toughness within the tempering temperature range. When the tempering temperature is 550°C, the tested steel has the best comprehensive mechanical properties, with tensile strength of 978 MPa, yield strength of 935 MPa, product of strength and elongation of 22.1 GPa·%, and impact absorbed energy of 100.3 J, demonstrating high strength and high toughness.

3.3 Effect of Tempering Temperature on Fracture Behavior

The morphologies of the propagation zone of the tensile fractures of the tested steel at different tempering temperatures are shown in Figure 3. It can be seen that they all exhibit ductile fracture morphologies characterized by fine dimples, accompanied by tearing edges (indicated by arrows) and tiny secondary cracks, which correspond to the high product of strength and elongation of the tested steel, indicating high plasticity. The morphologies of the propagation zone of the impact fractures of the tested steel at different tempering temperatures are shown in Figure 4. It can be seen that they all exhibit dimple morphologies, with shallow and small dimples accompanied by tearing edges (see Figure 4(c), arrow), which correspond to the high impact absorbed energy, indicating high toughness of the tested steel.

4. Conclusions

- The self-developed steel for deep well oil casing obtains tempered sorbite within the tempering temperature range of 500-600°C, with the degree of recovery of the lath martensite structure continuously increasing, and the carbides continuously spheroidizing and dispersing.

- Within the tempering temperature range of 500-600°C, the tested steel exhibits high strength, plasticity, dan ketangguhan, with the product of strength and elongation ranging from 20.5 kepada 22.1 GPa·% and the impact absorbed energy ranging from 94.6 kepada 100.3 J.

- When the tempering temperature is 550°C, the tested steel has the best comprehensive mechanical properties: tensile strength of 978 MPa, yield strength of 935 MPa, product of strength and elongation of 22.1 GPa·%, and impact absorbed energy of 100.3 J.

Rujukan

-

- Knittel C R. Reducing petroleum consumption from transportation [J]. Journal of Economic Perspectives, 2012, 26(1): 93-118.

- Lu Xiaoqing, Li Qin, Li Chunxiang. Development of TP110H special casing for high-strength heavy oil thermal recovery wells J]. Paip Keluli, 2007, 36(5): 14-17.

- Li Zhoubo, Bi Zongyue, Zhang Feng, et al. Research and development of Q125 steel grade SEW oil casing [J]. Paip dan Tiub yang dikimpal, 2013, 36(8): 32-35.

- Zhang Yilong. Study on the microstructure and properties of corrosion-resistant steel for oil casing [D]. Chongqing: Chongqing University of Science and Technology, 2018.

- Peng Xianming. Research on the microstructure and mechanical properties of 100V-Cr-Mo oil casing material [D]. Lanzhou: Lanzhou University of Technology, 2012.

- Gu Zhengguan. Study on the influence law of controlled cooling process on the microstructure and properties of V140 oil casing D]. Shenyang: Northeastern University, 2019.

- Shen Yutao, Zuo Pengpeng, Wu Xiaochun. Effect of Mo on the thermal stability of 4Cr5Mo2V hot work die steel [J]. Heat Treatment of Metals, 2022, 47(12): 168-174.

- Zhou Jian, Pian Liping, Fang Feng, et al. Effect of Mo content on the microstructure and corrosion resistance of 9Cr18Mo steel [J]. Heat Treatment of Metals, 2023, 48(12): 244-249.

- Liu Bin. Study on the microstructure and properties of controlled forging and controlled cooling bainitic non-quenched and tempered steel D]. Beijing: Beijing Jiaotong University, 2022.

- Lei Ming. Study on the microstructure and mechanical properties of vanadium-alloyed medium manganese steel D]. Beijing: Beijing Jiaotong University, 2019.

- Hui W J, Zhang Y J, Zhao X L, et al. Very high cycle fatigue properties of Cr-Mo low-alloy steels containing vanadium-rich carbide precipitates [J]. Materials Science and Engineering A, 2016, 651: 311-320.

- Wu Dongsheng, Deng Wei, Wen Hui, et al. Effect of vanadium content on austenite grain growth of Cr-Mo-V steel for brake discs of 350 km/h high-speed trains J]. Heat Treatment of Metals, 2023, 48(9): 136-142.

- Kihira H, Ito S, Mizoguchi S, et al. Creation of alloy design concept for anti-fatigue steels with boron [J]. Zairyo-to-Kankyo, 2000, 49(1): 30-40.

- Zhou Cheng, Zhao Tan, Ye Qibin, et al. Effects of tempering temperature on microstructure and low-temperature toughness of 1000 MPa grade NiCrMoV low-carbon alloy steel J]. Acta Metallurgica Sinica, 2022, 58(12): 1557-1569.

- Yang Ying, Xu Hongliang, Wang Yubo, et al. Effect of different heat treatment processes on the microstructure and properties of large-thickness bridge steels [J]. Heat Treatment of Metals, 2023, 48(10): 23-28.