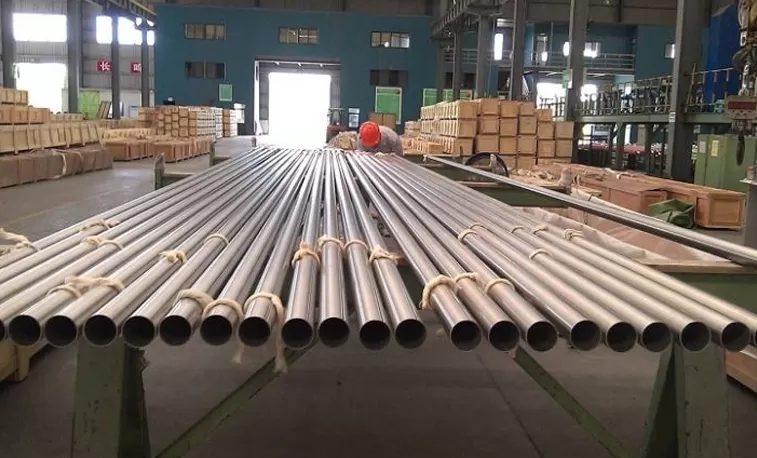

Nickel 200 Steel Tube (UNS N02200)

Nickel 200 Steel Tube (UNS N02200)

Nickel 200, also known as UNS N02200, is a commercially pure wrought nickel with excellent mechanical properties and resistance to a variety of corrosive environments. It is particularly noted for its resistance to caustic alkalis and its excellent thermal and electrical conductivity.

Chemical Composition

The typical chemical composition of Nickel 200 is as follows:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 99.0 min |

| Copper (Cu) | 0.25 max |

| Iron (Fe) | 0.40 max |

| Manganese (Mn) | 0.35 max |

| Silicon (Si) | 0.35 max |

| Carbon (C) | 0.15 max |

| Sulfur (S) | 0.01 max |

Mechanical Properties

Nickel 200 exhibits good mechanical properties over a wide range of temperatures:

- Tensile Strength: 380 MPa (55 ksi) min

- Yield Strength (0.2% offset): 103 MPa (15 ksi) min

- Elongation: 40% min

- Hardness: 70 HRB max

Physical Properties

- Density: 8.89 g/cm³ (0.321 lb/in³)

- Melting Point: 1435°C (2615°F)

- Specific Heat Capacity: 0.11 cal/g-°C (at 20°C)

- Thermal Conductivity: 90.7 W/m·K (at 20°C)

- Electrical Resistivity: 0.096 µΩ·m (at 20°C)

- Modulus of Elasticity: 207 GPa (at 20°C)

- Poisson’s Ratio: 0.31 (at 20°C)

Industries Predominantly Using Nickel 200

- Chemical Processing:

- Manufacturing and handling of sodium hydroxide, particularly at temperatures above 300°C (572°F).

- Production of caustic soda, hydrochloric acid, and other chemicals.

- Electronics:

- Components such as anodes, cathodes, and battery components due to its excellent electrical conductivity.

- Aerospace and Defense:

- Parts that require resistance to corrosion and good mechanical properties at elevated temperatures.

- Food Processing:

- Equipment and machinery due to its resistance to food acids and alkalies.

Typical Manufacturing Specifications

- ASTM B161: Specification for Nickel Seamless Pipe and Tube

- ASTM B163: Specification for Seamless Nickel and Nickel Alloy Condenser and Heat Exchanger Tubes

- ASTM B725: Specification for Welded Nickel (UNS N02200/UNS N02201) and Nickel-Copper Alloy (UNS N04400) Pipe

- ASME SB161/SB163/SB725: Standards for nickel alloy seamless and welded pipe and tube

Available Tube Product Forms

- Seamless Tubing

- Welded Tubing

- Straight Lengths

- Coiled Tubing

Typical Applications

- Chemical Processing:

- Equipment and piping systems for handling caustic alkalis such as sodium hydroxide.

- Acid production and handling equipment.

- Electronics:

- Components in electronic applications requiring high electrical conductivity.

- Aerospace and Defense:

- Components exposed to corrosive environments and high temperatures.

- Food Processing:

- Equipment and storage vessels for food and beverage industries.

Welding and Fabrication Characteristics

Welding

- Weldability:

- Nickel 200 can be welded using conventional welding methods such as Gas Tungsten Arc Welding (GTAW/TIG), Gas Metal Arc Welding (GMAW/MIG), and Shielded Metal Arc Welding (SMAW).

- Filler Metals: Typically, matching composition filler metals such as ERNi-1 are used.

- Preheating and Post-Weld Heat Treatment (PWHT):

- Preheating: Generally not required. However, cleanliness is crucial to prevent contamination.

- PWHT: Not typically required for Nickel 200, but can be performed to relieve stresses if necessary.

- Weld Defects and How to Avoid Them:

- Porosity: Ensure clean surfaces and proper shielding gases to minimize porosity.

- Cracking: Nickel 200 is generally resistant to cracking, but control welding parameters to avoid solidification cracking.

Fabrication

- Machining:

- General: Nickel 200 is relatively easy to machine compared to other high-nickel alloys. It can be machined using standard techniques, but it work-hardens rapidly.

- Coolants: Use water-based coolants to reduce heat and friction, thereby extending tool life and improving surface finish.

- Tooling: Carbide tools are recommended for better performance.

- Forming:

- Cold Forming: Nickel 200 can be cold-formed using standard methods. It has good ductility, which allows for significant deformation without cracking.

- Hot Forming: Hot forming is typically conducted at temperatures between 650°C and 1230°C (1200°F and 2250°F). Proper temperature control is necessary to prevent grain growth and maintain mechanical properties.

- Heat Treatments:

- Annealing: Annealing is performed to soften the material and relieve stress. Typical annealing temperatures range from 705°C to 925°C (1300°F to 1700°F), followed by air cooling.

- Stress Relieving: Stress relieving can be performed at temperatures between 480°C and 750°C (900°F and 1380°F).

- Surface Cleaning:

- Pickling: Use a pickling solution of sulfuric acid and nitric acid to remove oxides and scale formed during heat treatment or welding.

- Mechanical Cleaning: Grinding and brushing are suitable for removing surface contaminants, but care should be taken to avoid embedding iron particles, which could lead to corrosion.

Best Practices for Welding and Fabrication

- Cleanliness: Ensure a clean work environment. Contaminants such as sulfur, phosphorus, lead, and zinc can lead to weld defects and corrosion issues.

- Tooling: Use dedicated tools for Nickel 200 to avoid cross-contamination from other metals.

- Controlled Environment: Perform welding and fabrication in a controlled environment to minimize the introduction of impurities.

- Training: Ensure that welders and fabricators are specifically trained for handling Nickel 200 to achieve the best results.

Conclusion

Nickel 200 (UNS N02200) is a versatile material with excellent corrosion resistance, mechanical properties, and conductivity. It is widely used across various industries, including chemical processing, electronics, aerospace, and food processing. By adhering to best practices in welding and fabrication, engineers and fabricators can ensure high-quality results and reliable performance in their applications.