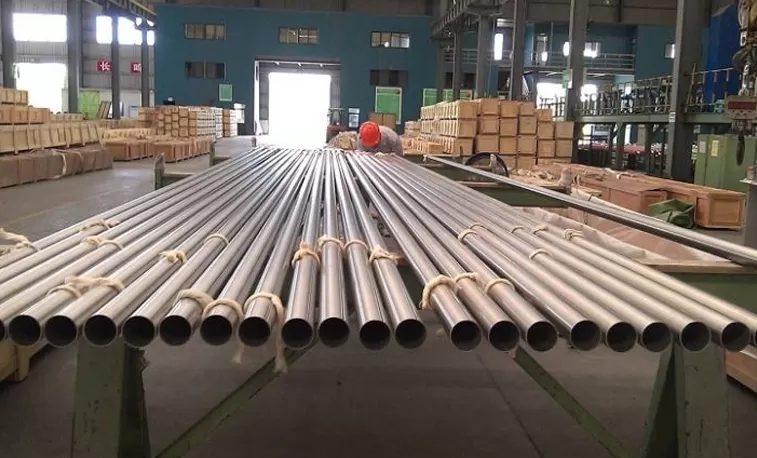

Nickel 690 Alloy Steel Tubes (UNS N06690 / WNR 2.4642)

Nickel 690 Alloy Steel Tubes (UNS N06690 / WNR 2.4642)

Nickel 690, also known as Inconel 690, is a high-chromium nickel alloy known for its excellent resistance to many corrosive media and high-temperature environments. This alloy offers exceptional resistance to oxidizing chemicals and environments, making it a popular choice for applications in nuclear power, chemical processing, and other industries requiring high-performance materials.

Chemical Composition

The chemical composition of Nickel 690 is as follows:

| Element | Composition (wt%) |

|---|---|

| Nickel (Ni) | 58.0–63.0 |

| Chromium (Cr) | 27.0–31.0 |

| Iron (Fe) | 7.0–11.0 |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.50 max |

| Copper (Cu) | 0.50 max |

| Carbon (C) | 0.05 max |

| Sulfur (S) | 0.015 max |

Mechanical Properties

Nickel 690 exhibits robust mechanical properties, making it suitable for high-stress environments. Typical mechanical properties include:

- Tensile Strength: 580 MPa (84 ksi) min

- Yield Strength (0.2% offset): 240 MPa (35 ksi) min

- Elongation: 30% min

- Hardness: 150-200 HB

Physical Properties

- Density: 8.19 g/cm³ (0.296 lb/in³)

- Melting Range: 1343-1377°C (2450-2510°F)

- Specific Heat Capacity: 0.102 cal/g-°C (at 20°C)

- Thermal Conductivity: 14.8 W/m·K (at 20°C)

- Electrical Resistivity: 1.09 µΩ·m (at 20°C)

- Modulus of Elasticity: 205 GPa (at 20°C)

- Poisson’s Ratio: 0.31 (at 20°C)

Industries Predominantly Using This Grade

-

- Nuclear Power:

- Steam generator tubing

- Reactor core components

- Nuclear Power:

- Chemical Processing:

- Heat exchangers

- Reactor vessels

- Aerospace:

- Gas turbine components

- Exhaust systems

- Power Generation:

- Furnace components

- Superheater tubing

Typical Manufacturing Specifications

- ASTM B163: Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

- ASTM B167: Specification for Nickel-Chromium-Iron Alloys (UNS N06690) Welded Pipe and Tube

- ASME SB163/SB167: Standards for nickel and nickel alloy seamless and welded pipe and tube

Available Tube Product Forms

- Seamless Tubing

- Welded Tubing

- Straight Lengths

- Coiled Tubing

Typical Applications

- Nuclear Power:

- Steam generator tubing

- Fuel reprocessing components

- Chemical Processing:

- Heat exchangers and condensers

- Vessels and piping handling corrosive chemicals

- Aerospace:

- Jet engine components

- High-temperature exhaust systems

- Power Generation:

- Furnace components

- Superheater and reheater tubing

Key Features and Benefits

- Corrosion Resistance:

- Excellent resistance to oxidizing and reducing environments.

- Superior resistance to sulfuric and nitric acids.

- High resistance to stress-corrosion cracking and intergranular attack.

- High Temperature Stability:

- Maintains mechanical properties and corrosion resistance at elevated temperatures.

- Mechanical Strength:

- High strength and toughness, suitable for high-stress applications.

- Fabricability:

- Good weldability and formability, allowing for complex shapes and structures.

Conclusion

Nickel 690 (UNS N06690 / WNR 2.4642) is a high-performance alloy well-suited for applications requiring excellent corrosion resistance and high-temperature stability. Its robust mechanical properties and versatility make it a preferred choice for industries such as nuclear power, chemical processing, aerospace, and power generation. With its superior resistance to various corrosive media and excellent mechanical properties, Nickel 690 ensures reliable and durable performance in demanding environments.

Welding and Fabrication Characteristics of Nickel 690 (UNS N06690 / WNR 2.4642)

Nickel 690, known for its excellent corrosion resistance and high-temperature stability, also exhibits favorable welding and fabrication characteristics. Here are detailed insights into its behavior during these processes:

Welding Characteristics

- Weldability:

- General: Nickel 690 is known for good weldability. It can be welded using various methods, including Gas Tungsten Arc Welding (GTAW/TIG), Gas Metal Arc Welding (GMAW/MIG), Shielded Metal Arc Welding (SMAW), and Submerged Arc Welding (SAW).

- Filler Metals: Commonly used filler metals include ERNiCr-3 and ERNiCrMo-3 for GTAW and GMAW, and ENiCrFe-3 for SMAW. These fillers help achieve welds with properties closely matching the base metal.

- Preheating and Post-Weld Heat Treatment (PWHT):

- Preheating: Typically, preheating is not required for Nickel 690. However, maintaining a clean welding area is crucial to prevent contamination.

- PWHT: Post-weld heat treatment is often not necessary but can be applied to relieve residual stresses, especially in thick sections. A stress-relief anneal can be conducted at temperatures between 870°C and 980°C (1600°F and 1800°F).

- Weld Defects and How to Avoid Them:

- Porosity: Ensuring a clean work environment and using appropriate shielding gases can minimize porosity.

- Cracking: Nickel 690 is resistant to hot cracking due to its high chromium content, but attention should be given to welding parameters and techniques to avoid problems like solidification cracking.

Fabrication Characteristics

- Machining:

- General: Nickel 690 is moderately difficult to machine due to its high strength and work hardening characteristics. Using carbide tools and low cutting speeds with high feed rates can improve machinability.

- Coolants: Liberal use of cutting fluids helps in cooling and lubrication during machining, extending tool life and improving surface finish.

- Forming:

- Cold Forming: Nickel 690 can be cold-formed using conventional techniques. However, due to its high work hardening rate, intermediate annealing may be required for extensive deformation.

- Hot Forming: Hot forming is generally done at temperatures between 900°C and 1230°C (1650°F and 2250°F). Proper temperature control is essential to avoid cracking and to ensure uniformity of the material properties.

- Heat Treatments:

- Solution Annealing: Performed at temperatures between 1000°C and 1150°C (1830°F and 2100°F), followed by rapid quenching. This process helps in dissolving carbides and other phases to achieve a homogeneous microstructure.

- Stress Relief: As mentioned, stress relief annealing can be performed to reduce residual stresses from welding or forming operations.

- Surface Cleaning:

- Pickling: Nickel 690 can be pickled using a solution of nitric and hydrofluoric acids to remove oxides and scale formed during welding or heat treatment.

- Mechanical Cleaning: Grinding and brushing can also be used to clean the surface, but care should be taken to avoid contamination with iron particles, which can lead to corrosion.

Best Practices for Welding and Fabrication

- Cleanliness: Maintaining a clean work environment is crucial. Contaminants such as sulfur, phosphorus, lead, and zinc can lead to weld defects and corrosion issues.

- Tooling: Use dedicated tools for Nickel 690 to avoid cross-contamination from other metals.

- Controlled Environment: If possible, perform welding and fabrication in a controlled environment to minimize the introduction of impurities.

- Training: Ensure that welders and fabricators are trained specifically for handling high-nickel alloys to achieve the best results.