Различия между обсадными масляными трубами N80 и L80

Differences Between API 5CT N80 and L80 Oil Casing Pipes

Введение

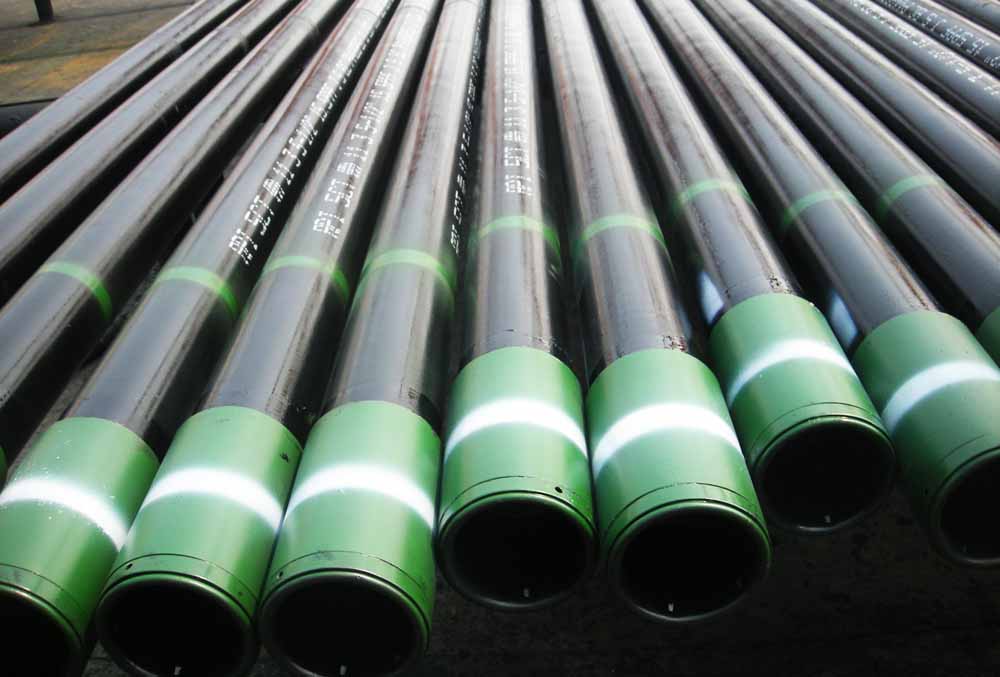

API 5CT is a specification for casing and tubing in the oil and gas industry, detailing the requirements for various grades of steel pipes. N80 and L80 are two commonly used grades within this specification, each with distinct properties and applications. Understanding the differences between these two grades is crucial for selecting the appropriate pipe for specific drilling and production conditions.

Химический состав

N80

N80 casing pipes are made from carbon steel with a moderate level of alloying elements to provide a balance of strength and toughness. Типичный химический состав включает:

| Элемент | Состав (%) |

|---|---|

| Углерод (С) | 0.28-0.40 |

| Марганец (Мин.) | 1.25-1.60 |

| Фосфор (П) | 0.030 Макс |

| сера (С) | 0.030 Макс |

| Кремний (И) | 0.20-0.35 |

Л80

L80 casing pipes are also made from carbon steel, but they generally contain higher levels of alloying elements to enhance their mechanical properties and corrosion resistance. Типичный химический состав включает:

| Элемент | Состав (%) |

|---|---|

| Углерод (С) | 0.25-0.48 |

| Марганец (Мин.) | 0.45-1.90 |

| Фосфор (П) | 0.030 Макс |

| сера (С) | 0.030 Макс |

| Хром (Кр) | 0.25-1.25 |

| Никель (В) | 0.25 Макс |

| Медь (Cu) | 0.25 Макс |

| Кремний (И) | 0.20-0.35 |

Механические свойства

N80

The mechanical properties of N80 casing pipes are designed to ensure durability and reliability under moderate operational conditions. Типичные механические свойства включают в себя:

- Предел прочности: 689-896 МПа (100-130 кси)

- Предел текучести: Минимум 552 МПа (80 кси)

- Удлинение: Минимум 15% в 2 дюймы

Л80

L80 casing pipes have enhanced mechanical properties, making them suitable for more demanding applications, including sour service environments. Типичные механические свойства включают в себя:

- Предел прочности: 655-885 МПа (95-128 кси)

- Предел текучести: Минимум 552 МПа (80 кси)

- Удлинение: Минимум 15% в 2 дюймы

- Твердость: Maximum 23 HRC for L80-1 and 25 HRC for L80-9Cr and L80-13Cr

Термическая обработка

N80

N80 casing pipes generally undergo a normalizing heat treatment process to refine the grain structure and improve toughness and strength. The two common heat treatment processes for N80 are:

- Н80-1: Normalized

- N80Q: Quenched and tempered

Л80

L80 casing pipes are typically quenched and tempered to achieve the desired mechanical properties and to enhance their resistance to sulfide stress cracking (ССК) in sour service environments. There are also different types of L80 pipes based on their heat treatment and alloying elements:

- Л80-1: Quenched and tempered

- Л80-9Кр: Quenched and tempered with 9% Хром

- Л80-13Кр: Quenched and tempered with 13% Хром

Приложения

N80

N80 casing pipes are used in various drilling and production operations where moderate strength and toughness are required. They are suitable for:

- Standard oil and gas wells

- Moderate depth wells

- Wells without significant sour gas presence

Л80

L80 casing pipes are designed for more demanding applications, particularly where resistance to corrosion and sulfide stress cracking is crucial. They are suitable for:

- Sour service environments

- Deeper wells with higher pressures

- Wells with significant hydrogen sulfide (H₂S) presence

- High-temperature and high-pressure (HTHP) wells

Расходы

N80

N80 casing pipes are generally less expensive than L80 due to their lower alloy content and less stringent heat treatment processes. They are a cost-effective choice for standard drilling and production operations.

Л80

L80 casing pipes are more expensive due to their higher alloy content and more complex heat treatment processes. The additional cost is justified by their enhanced mechanical properties and corrosion resistance, making them suitable for more challenging drilling environments.

Краткое содержание

| Свойство | N80 | Л80 |

|---|---|---|

| Химический состав | Moderate alloy content | Higher alloy content, including Chromium |

| Механические свойства | Предел прочности: 689-896 МПа<br>Предел текучести: ≥552 MPa<br>Удлинение: ≥15% | Предел прочности: 655-885 МПа<br>Предел текучести: ≥552 MPa<br>Удлинение: ≥15%<br>Твердость: ≤23 HRC (Л80-1) or ≤25 HRC (L80-9Cr/13Cr) |

| Термическая обработка | Normalized or Quenched and Tempered | Quenched and Tempered |

| Приложения | Standard wells, moderate depth, no significant sour gas | Sour service, deeper wells, HTHP wells |

| Расходы | Менее дорогой | More expensive due to enhanced properties |

Choosing between N80 and L80 casing pipes depends on the specific requirements of the drilling and production operations, including the presence of corrosive environments, well depth, and pressure conditions.

Detailed Comparison Table

To provide a clearer side-by-side comparison, here is a detailed table highlighting the key differences between N80 and L80 casing pipes:

| Attribute | N80 | Л80 |

|---|---|---|

| Химический состав | Moderate alloy content, primarily carbon and manganese | Higher alloy content, including Chromium (Кр), Никель (В), и медь (Cu) |

| Термическая обработка | Normalized (Н80-1) or Quenched and Tempered (N80Q) | Quenched and Tempered (Л80-1), with specific treatments for L80-9Cr and L80-13Cr |

| Предел прочности | 689-896 МПа (100-130 кси) | 655-885 МПа (95-128 кси) |

| Предел текучести | Минимум 552 МПа (80 кси) | Минимум 552 МПа (80 кси) |

| Удлинение | Минимум 15% в 2 дюймы | Минимум 15% в 2 дюймы |

| Твердость | Typically not specified | Maximum 23 СПЧ (Л80-1) или 25 СПЧ (L80-9Cr and L80-13Cr) |

| Коррозионная стойкость | Умеренный, not suitable for sour service | Высокий, suitable for sour service and H₂S environments |

| Расходы | Lower due to simpler alloying and heat treatment | Higher due to complex alloying and heat treatment |

| Приложения | Standard oil and gas wells, moderate depth wells, non-sour environments | Sour service environments, deeper wells, high-temperature and high-pressure wells, wells with H₂S presence |

Заключение

Selecting the right casing pipe grade is critical for the success and safety of drilling and production operations in the oil and gas industry. Here is a summary to help make an informed decision:

- N80 Casing Pipes: Suitable for standard drilling operations where moderate strength and toughness are required. They are cost-effective and appropriate for non-sour environments and moderate well depths.

- L80 Casing Pipes: Designed for challenging environments, including those with sour gas (H₂S) presence. They offer superior corrosion resistance and mechanical properties, making them ideal for deeper, высокое давление, and high-temperature wells.

By understanding the differences in chemical composition, механические свойства, heat treatment, приложения, and costs, operators can choose the most appropriate casing pipe grade to ensure well integrity and operational efficiency.