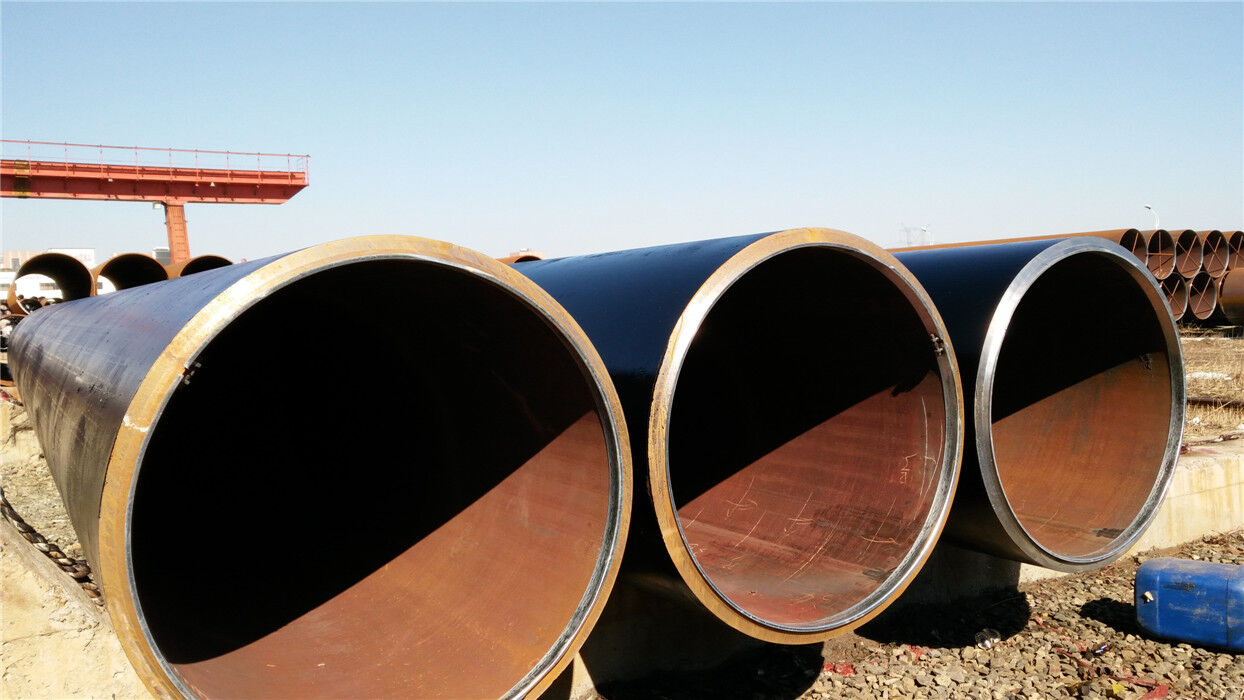

SAWL Steel Pipe

SAWL (Submerged Arc Welded Longitudinal) Steel Pipe

SAWL (Submerged Arc Welded Longitudinal) steel pipes are widely used in industries requiring high-strength and high-quality welded pipes. These pipes are manufactured using a longitudinal submerged arc welding process, which provides excellent mechanical properties and strong weld integrity, making them suitable for critical applications such as oil and gas pipeline systems, structural projects, and more.

Key Features

- Manufacturing Process: Longitudinal Submerged Arc Welding (LSAW)

- Grades:

- API 5L (various grades such as X42, X52, X60, X70)

- ASTM A252

- ISO 3183

- Sizes:

- Outside Diameter: 16” to 64” (406.4 mm to 1625.6 mm)

- Wall Thickness: 0.250” to 2.0” (6.4 mm to 50.8 mm)

- Lengths: Up to 12 meters or custom lengths as per requirements

Chemical Composition

The chemical composition varies based on the specific grade and standard. Below is a general example for API 5L Grade X52:

| Element | Maximum Percentage (%) |

|---|---|

| Carbon (C) | 0.22 |

| Manganese (Mn) | 1.40 |

| Phosphorus (P) | 0.025 |

| Sulfur (S) | 0.015 |

| Silicon (Si) | 0.45 |

Mechanical Properties

Mechanical properties also depend on the specific grade and standard. Below is an example for API 5L Grade X52:

| Property | Value |

|---|---|

| Yield Strength (min) | 52,000 psi (360 MPa) |

| Tensile Strength (min) | 66,000 psi (455 MPa) |

| Elongation (min) | 21% |

SAWL Manufacturing Process

- Plate Selection: High-quality steel plates are selected according to the required specifications.

- Edge Preparation: Edges of the steel plates are trimmed and beveled to ensure proper weld seam preparation.

- Forming: Steel plates are formed into cylindrical shapes using a press or roll bending machine.

- Tack Welding: The edges of the formed plates are tack-welded to hold the shape.

- Submerged Arc Welding: The longitudinal seam is welded using submerged arc welding both internally and externally, ensuring deep penetration and strong weld integrity.

- Heat Treatment: Welded pipes may undergo heat treatment to relieve stress and improve mechanical properties.

- Inspection: Pipes undergo various non-destructive tests such as ultrasonic testing and radiographic testing to ensure weld quality and pipe integrity.

- Hydrostatic Testing: Each pipe is subjected to hydrostatic pressure testing to verify its pressure resistance.

- Finishing: Final processes include end beveling, coating, and marking as per customer specifications.

Applications

- Oil and Gas Transportation: Used in pipelines for transporting oil, gas, and other fluids.

- Water Transmission: Suitable for water supply and drainage systems.

- Structural Applications: Used in the construction of bridges, buildings, and other infrastructure projects.

- Piling Foundations: Employed as piling pipes in foundation construction.

- Mechanical Applications: Utilized in various industrial and mechanical applications.

Advantages

- High Strength: Capable of withstanding high pressure and stress.

- Strong Weld Integrity: Longitudinal seam welding provides a robust and reliable seam.

- Dimensional Accuracy: Ensures precise control over pipe dimensions.

- Quality Assurance: Extensive testing ensures compliance with standards and high-quality output.

- Versatility: Suitable for a wide range of applications and environments.

- Large Diameter Production: Allows for the production of large diameter pipes suitable for demanding applications.

Conclusion

SAWL steel pipes are ideal for critical applications that require high strength, durability, and reliable weld integrity. These pipes are extensively used in the oil and gas industry, water transmission systems, structural projects, and more. The longitudinal submerged arc welding process ensures strong welds and precise dimensions, making SAWL pipes a dependable choice for various engineering and construction needs.