Scaffolding Galvanized Steel Pipe

Product Overview:

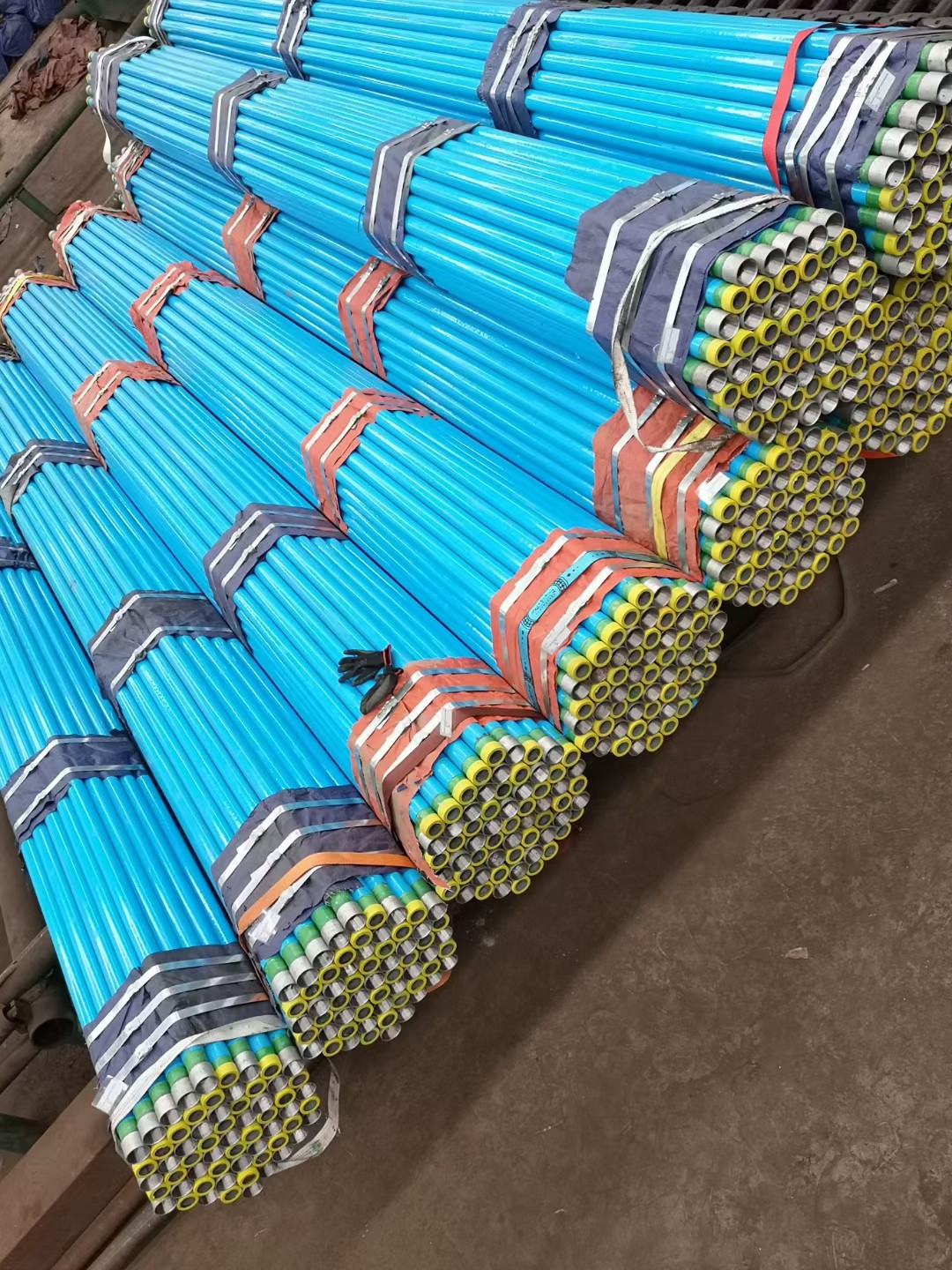

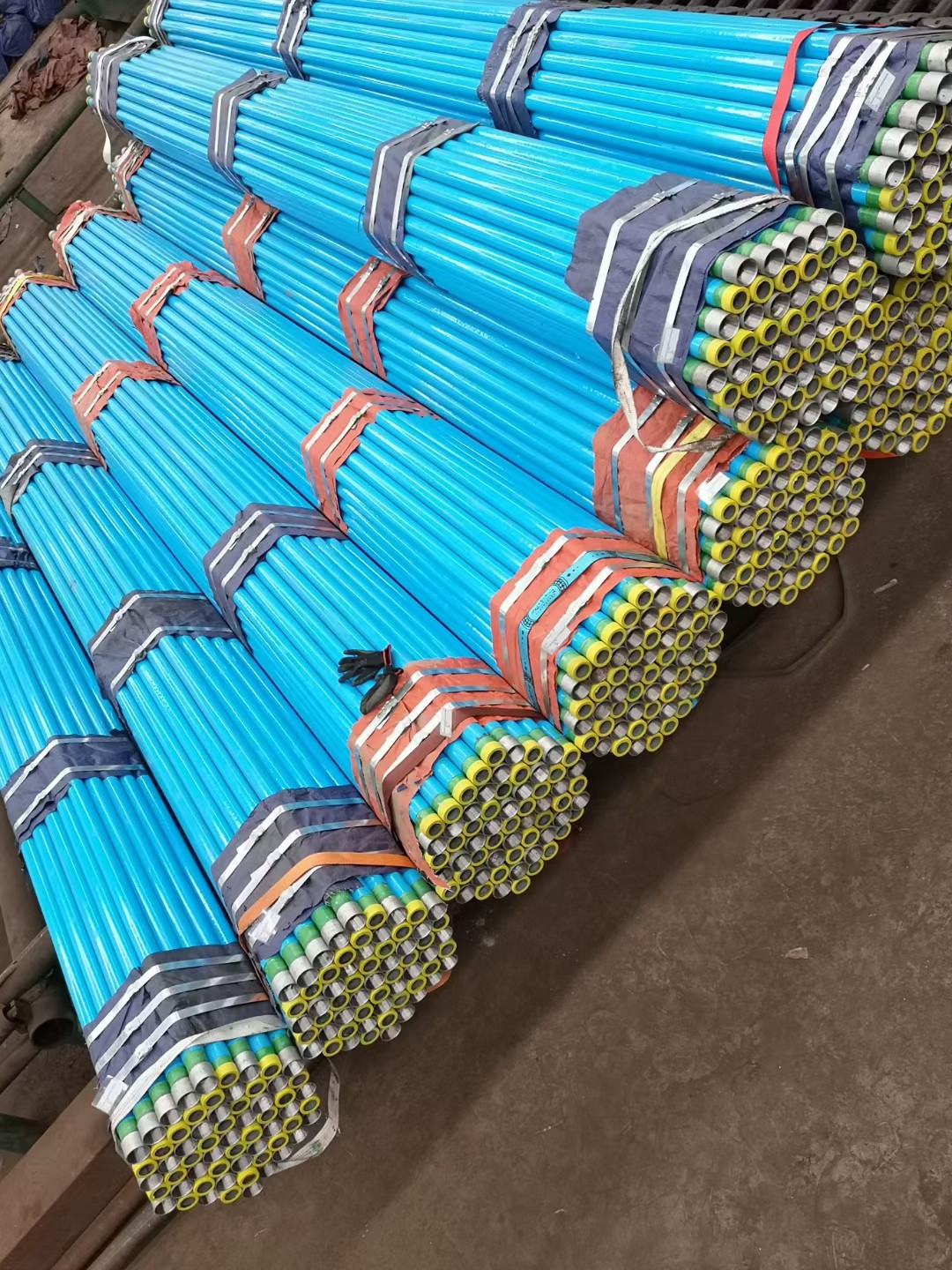

Introducing the Galvanised Scaffold Tube , a top-tier, robust construction component crafted to deliver unmatched support and stability across diverse scaffolding applications. Boasting a tensile strength of 420N/mm², this tube is engineered to bear substantial loads, making it an essential asset for construction projects prioritizing safety and dependability. This tensile strength rating signifies the utmost stress the tube can endure when stretched or pulled before any significant contraction occurs in its cross-section. The 420N/mm² capacity ensures these tubes effortlessly withstand the demanding stresses typical of construction environments.

Our scaffold tubes are meticulously manufactured with an emphasis on durability and longevity. Each tube undergoes a galvanisation process, applying a protective zinc coating that not only guards the steel against harsh elements but also offers resistance to rust and corrosion. This galvanisation enhances the tubes’ resilience in outdoor settings, where they face varying weather conditions. Such treatment guarantees the scaffold tube retains its structural integrity and appearance over time, extending its service life and minimizing the need for frequent replacements or repairs.

Technical Specifications:

- Name: Galvanised Scaffold Tube

- Diameter: 48.3mm

- Tensile Strength: 420N/mm²

- Yield Strength: 245N/mm²

- Thickness: 3.2mm

- Weight: 6.4kg/m

- Application: Scaffolding

- Standard: EN39

- Material: Galvanised Steel

- Surface Treatment: Galvanised

Applications:

Compliant with the EN39 standard, Bythai Scaffold Tubes integrate seamlessly with various scaffolding systems worldwide. They are ideal for a multitude of scenarios, from constructing new buildings and bridges to renovating and repairing existing structures. The sturdy nature of the bs1139 scaffolding tube ensures safety and stability, which is crucial in high-risk environments like construction sites.

With a robust supply capacity of 1000 tons per month, Bythai Scaffolding can accommodate orders for both small and large projects, ensuring a steady supply chain for its clients. Whether for temporary structures, staging, access towers, or shoring, this metal tubing is a fundamental resource for ensuring projects are completed efficiently, safely, and to the highest quality standards.

Our Galvanised Scaffold Tube is a high-strength, durable solution for your scaffolding needs. Manufactured by Bythai Scaffolding, this scaffold tube is designed to meet the demands of various construction environments. Featuring a 48.3mm diameter, it ensures robust performance and compatibility with standard scaffolding systems. Each tube is crafted from high-quality Galvanised Steel with a yield strength of 245N/mm² and tensile strength of 420N/mm², offering exceptional structural integrity. For large-scale projects, our hot-dip galvanized scaffolding steel tube guarantees maximum corrosion resistance and longevity. Order your galvanized scaffold tubes from Bythai Scaffolding and enjoy our reliable SGS certified products, quick delivery times, and efficient service.

1. Ringlock scaffolding

Ringlock scaffolding is a new type of scaffolding, widely used in elevated bridge construction, tunnel construction, plant, elevated water towers, power plants, oil refineries, span scaffolding, storage shelves, interior decoration, stage erection, sports bleachers and other projects.

?

?

2. Cuplock Scaffolding

CUPLOCK scaffold system is very veratile way of erection & dismantling. You can erect in what ever structural configuration you want. The material in this system in single pipes only, so it is very easy to transport, transfer and erect. It requires less space for storage, no loose items are there which gets misplaced, the locking system here is such designed that no chances of accidents.

?

?

3.Kwikstage Scaffolding

4.Light duty prop-spanish prop

|

Min Height |

Max Height |

Inner Tube |

Outer Tube |

Tube Thk |

|

0.6m |

1.1m |

40mm |

48mm |

1.4-2.5mm |

|

0.8m |

1.4m |

40mm |

48mm |

1.4-2.5mm |

|

1.6m |

2.9m |

40mm |

48mm |

1.4-2.5mm |

|

1.8m |

3.2m |

40mm |

48mm |

1.4-2.5mm |

|

2.0m |

3.6m |

40mm |

48mm |

1.4-2.5mm |

|

2.2m |

4.0m |

40mm |

48mm |

1.4-2.5mm |

5.Light duty prop-Italian prop

|

Min Height |

Max Height |

Inner Tube |

Outer Tube |

Tube Thk |

|

1.6m |

2.9m |

48mm |

56mm |

1.4-2.5mm |

|

1.8m |

3.2m |

48mm |

56mm |

1.4-2.5mm |

|

2.0m |

3.5m |

48mm |

56mm |

1.4-2.5mm |

|

2.0m |

3.6m |

48mm |

56mm |

1.4-2.5mm |

|

2.2m |

4.0m |

48mm |

56mm |

1.4-2.5mm |

6.Heavy duty prop-Middle east prop

|

Min Height |

Max Height |

Inner Tube |

Outer Tube |

Tube Thk |

|

1.6m |

2.9m |

48mm |

60mm |

1.4-4.0mm |

|

1.8m |

3.2m |

48mm |

60mm |

1.4-4.0mm |

|

2.0m |

3.5m |

48mm |

60mm |

1.4-4.0mm |

|

2.0m |

3.6m |

48mm |

60mm |

1.4-4.0mm |

|

2.2m |

4.0m |

48mm |

60mm |

1.4-4.0mm |

|

3.0m |

5.0m |

48mm |

60mm |

1.4-4.0mm |

|

3.5m |

6.0m |

48mm |

60mm |

1.4-4.0mm |

7.Push-pull Prop

|

Min Height |

Max Height |

Inner Tube |

Outer Tube |

Tube Thk |

|

1.6m |

2.9m |

48mm |

60mm |

1.4-4.0mm |

|

1.8m |

3.2m |

48mm |

60mm |

1.4-4.0mm |

|

2.0m |

3.5m |

48mm |

60mm |

1.4-4.0mm |

|

2.0m |

3.6m |

48mm |

60mm |

1.4-4.0mm |

|

2.2m |

4.0m |

48mm |

60mm |

1.4-4.0mm |

|

3.0m |

5.0m |

48mm |

60mm |

1.4-4.0mm |

|

3.5m |

6.0m |

48mm |

60mm |

1.4-4.0mm |

8.Tripod

|

Can be customized accordingly |

||

|

6.8kg |

7.45kg |

8.4kg |