Scaffolding pipe: Understanding Its Necessity, Assembly, Materials, and Safety

Comprehensive Guide to Scaffolding Pipe: Understanding Its Necessity, Assembly, Materials, and Safety

Introduction

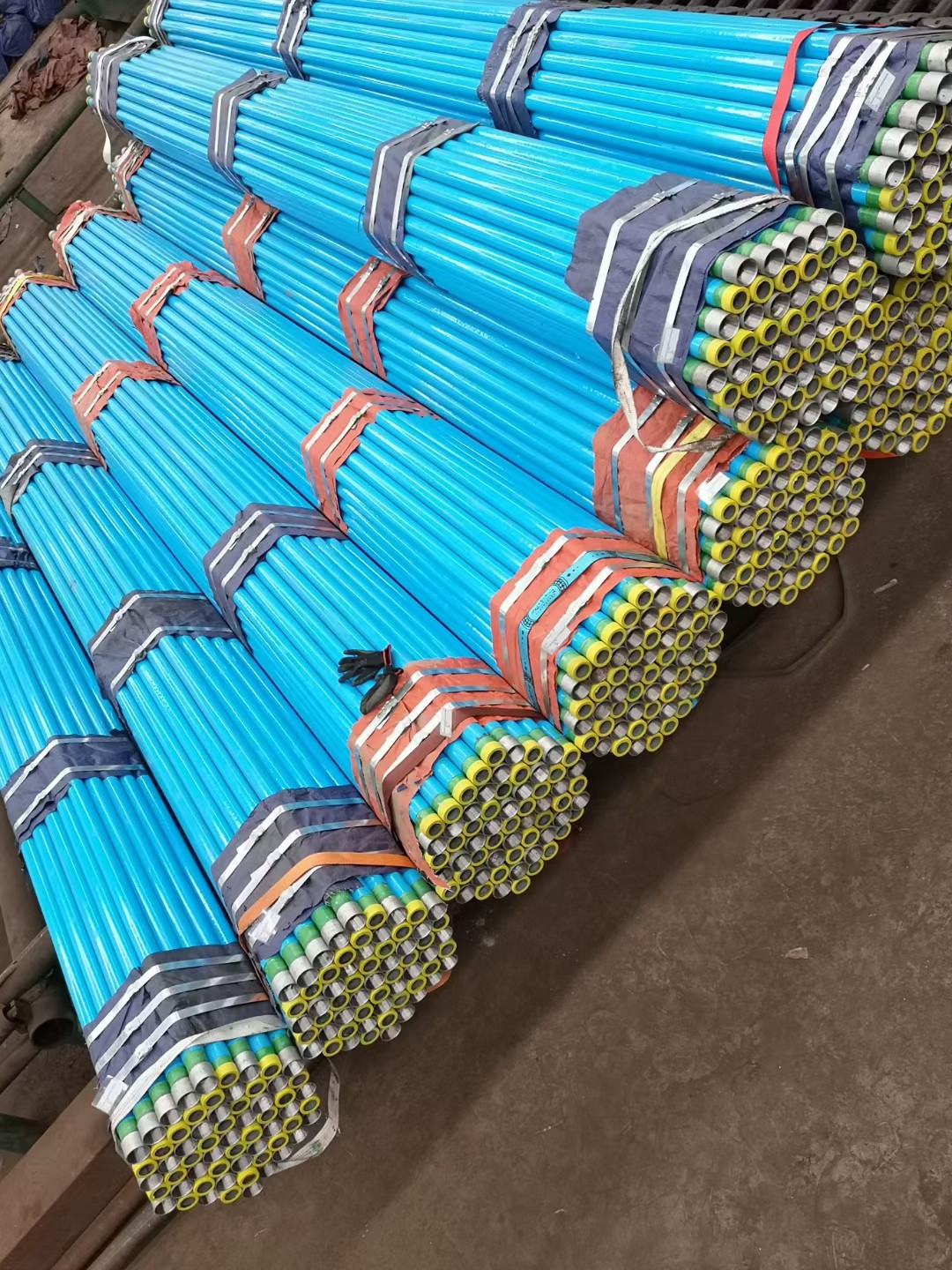

Scaffolding Pipe is an integral part of the construction industry, providing temporary structures that support workers and materials during the building, maintenance, or repair of structures. This guide explores the necessity of Scaffolding Pipe, how it is assembled, the materials used in its construction, and the processes involved in inspecting it for safety. Through this comprehensive exploration, we aim to provide a thorough understanding of Scaffolding Pipe’s role in ensuring efficiency and safety in construction projects.

1. What is Scaffolding Pipe, and Why is it Necessary?

1.1 Definition of Scaffolding Pipe

Scaffolding Pipe is a temporary framework used to support workers and materials during the construction, maintenance, or repair of buildings and other structures. It provides a safe and stable platform for workers to perform tasks at heights that would otherwise be inaccessible.

1.2 Types of Scaffolding Pipe

- Supported Scaffolding Pipe: The most common type, consisting of one or more platforms supported by rigid, load-bearing members like poles, legs, frames, or outriggers.

- Suspended Scaffolding Pipe: Platforms suspended by ropes or other non-rigid means from an overhead structure, often used for tasks on tall buildings.

- Rolling Scaffolding Pipe: Similar to supported Scaffolding Pipe but equipped with casters or wheels for easy movement.

- Cantilever Scaffolding Pipe: Supported on one end and free on the other, used in situations where the ground does not support a standard base.

- Aerial Lifts: Include devices like cherry pickers or boom lifts that can be moved and positioned as needed.

1.3 Necessity of Scaffolding Pipe

Scaffolding Pipe is necessary for several reasons:

- Access: Provides access to high or hard-to-reach areas, enabling workers to perform tasks safely and efficiently.

- Safety: Offers a stable and secure platform that reduces the risk of falls and accidents.

- Efficiency: Facilitates the movement of workers and materials, improving productivity on construction sites.

- Versatility: Can be configured in various ways to suit different tasks and structures, making it adaptable to a wide range of projects.

1.4 Historical Context

Scaffolding Pipe has been used for centuries, with evidence of its use in ancient Egypt and China. Over time, the design and materials have evolved, but the fundamental purpose of providing safe access to elevated work areas remains unchanged.

2. How is Scaffolding Pipe Assembled?

2.1 Planning and Design

Before assembly begins, careful planning and design are essential:

- Site Assessment: Evaluate the site to determine the type and configuration of Scaffolding Pipe required.

- Load Calculations: Calculate the expected loads, including workers, materials, and equipment, to ensure the Scaffolding Pipe can support them safely.

- Design Specifications: Develop detailed design specifications, including dimensions, materials, and connections, to guide the assembly process.

2.2 Components of Scaffolding Pipe

Scaffolding Pipe consists of several key components:

- Standards: Vertical tubes that transfer the weight of the Scaffolding Pipe to the ground.

- Ledgers: Horizontal tubes that connect the standards and provide lateral support.

- Transoms: Horizontal tubes placed at right angles to the ledgers, supporting the platforms.

- Platforms: The working surfaces, typically made of wood or metal planks.

- Braces: Diagonal tubes that provide stability and prevent swaying.

- Couplers: Connectors used to join tubes together.

- Base Plates and Sole Boards: Distribute the load from the standards to the ground.

2.3 Assembly Process

The assembly of Scaffolding Pipe involves several steps:

- Foundation Preparation: Ensure the ground is level and stable, using base plates and sole boards to distribute the load.

- Erecting Standards: Position the standards at regular intervals, securing them with base plates.

- Installing Ledgers and Transoms: Connect the standards with ledgers and transoms, using couplers to secure the connections.

- Adding Braces: Install diagonal braces to enhance stability and prevent movement.

- Placing Platforms: Lay the platforms across the transoms, ensuring they are secure and level.

- Safety Features: Install guardrails, toe boards, and access ladders to enhance safety.

2.4 Best Practices for Assembly

- Follow Manufacturer Instructions: Adhere to the manufacturer’s guidelines and specifications for assembly.

- Use Trained Personnel: Ensure that only trained and competent personnel are involved in the assembly process.

- Inspect During Assembly: Conduct inspections at each stage of assembly to identify and address any issues.

3. What Materials are Used to Build Scaffolding Pipe?

3.1 Common Materials

Several materials are commonly used in the construction of Scaffolding Pipe:

- Steel: The most widely used material, known for its strength, durability, and load-bearing capacity. Steel Scaffolding Pipe is suitable for heavy-duty applications and can withstand harsh environmental conditions.

- Aluminum: Lightweight and resistant to corrosion, aluminum Scaffolding Pipe is easy to transport and assemble. It is ideal for projects where mobility and ease of handling are important.

- Wood: Traditionally used for Scaffolding Pipe platforms, wood is still used in some applications, particularly for temporary or short-term projects. It is important to use high-quality, treated wood to ensure safety and durability.

- Fiberglass: Non-conductive and resistant to corrosion, fiberglass Scaffolding Pipe is used in environments where electrical safety is a concern, such as power plants or chemical facilities.

3.2 Material Selection Considerations

When selecting materials for Scaffolding Pipe, consider the following factors:

- Load Requirements: Choose materials that can support the expected loads, including workers, equipment, and materials.

- Environmental Conditions: Consider the environmental conditions, such as exposure to moisture, chemicals, or extreme temperatures, and select materials that can withstand these conditions.

- Mobility and Ease of Assembly: For projects that require frequent movement or reconfiguration, lightweight materials like aluminum may be preferred.

- Cost and Availability: Evaluate the cost and availability of materials, balancing budget constraints with performance requirements.

3.3 Innovations in Scaffolding Pipe Materials

Advancements in materials technology have led to innovations in Scaffolding Pipe, including:

- Composite Materials: The use of composite materials, such as carbon fiber, offers high strength-to-weight ratios and corrosion resistance, making them suitable for specialized applications.

- Modular Systems: Modular Scaffolding Pipe systems, made from standardized components, allow for quick and flexible assembly, reducing labor costs and project timelines.

4. How is Scaffolding Pipe Inspected for Safety?

4.1 Importance of Safety Inspections

Safety inspections are critical to ensuring the integrity and safety of Scaffolding Pipe structures. Regular inspections help identify potential hazards, prevent accidents, and ensure compliance with safety regulations.

4.2 Inspection Process

The inspection process involves several key steps:

- Pre-Assembly Inspection: Before assembly begins, inspect all components for damage, defects, or wear. Ensure that all parts are present and in good condition.

- During Assembly Inspection: Conduct inspections at each stage of assembly to verify that the Scaffolding Pipe is being erected according to design specifications and safety standards.

- Post-Assembly Inspection: Once assembly is complete, perform a thorough inspection to ensure that the Scaffolding Pipe is stable, secure, and free of hazards.

4.3 Key Inspection Points

During inspections, focus on the following key points:

- Structural Integrity: Check for signs of damage, corrosion, or wear on all components, including standards, ledgers, transoms, and braces.

- Connections and Couplers: Ensure that all connections and couplers are secure and properly tightened.

- Platforms and Guardrails: Verify that platforms are level, secure, and free of debris. Ensure that guardrails and toe boards are in place and meet safety standards.

- Access Points: Inspect access ladders and stairways for stability and proper installation.

4.4 Frequency of Inspections

The frequency of Scaffolding Pipe inspections depends on several factors:

- Regulatory Requirements: Follow local regulations and industry standards, which may specify inspection intervals.

- Project Duration and Complexity: For long-term or complex projects, conduct regular inspections to ensure ongoing safety.

- Environmental Conditions: In harsh or changing environmental conditions, increase the frequency of inspections to address potential issues.

4.5 Documentation and Record Keeping

Maintain detailed records of all inspections, including:

- Inspection Dates: Record the dates of all inspections and any follow-up actions taken.

- Inspection Findings: Document any issues identified during inspections and the corrective actions taken.

- Inspector Information: Include the names and qualifications of the inspectors conducting the inspections.