We produce seamless mechanical steel pipes, in the hot-rolled condition, close to your finished part size, which makes it very competitive compared to other forging or machining processes. You may also purchase tubes in sizes recommended to clean up at finished part dimensions, which allows for optimum material utilization. Our size range ranks among industry leaders, from 1″-24″ .

Tatrus stocks a huge selection of ASTM standard seamless mechanical steel tube, with sizes and styles to match any requirements. The ASTM standard steel pipe specification covers both hot-finished and cold-finished mechanical tubing in sizes up to 1″-24″ O.D.

We focus on continually improving the quality of our processes. With recent investments in an intermediate finishing line, water-blast descaling process, and continuous induction thermal treat facility, we strengthened our ability to offer quality, customized solutions. Our approach to manufacturing integrates our melting, rolling, piercing and finishing operations, helping to ensure quality control from start to finish. Our seamless mechanical tubing processes include piercing (rotary forging), thermal treatment, and testing and finishing.

mechanical Steel Pipe Materials & Manufacture

Steel used to produce mechanical steel pipe may be made by any process; if the purchaser requires a specified type of melting, please note this in your RFQ or when ordering. mechanical Steel Pipe must be made in a seamless process and either hot finished or cold finished, as specified.

Quality Standard

ASTM A 53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated

ASTM A519 Seamless Carbon and Alloy Steel Mechanical Tubing

GB/T8162 Seamless Steel Tubes for Structural Purposes

JIS G3441 Alloy Steel Tubes for Machine Purposes

JIS G3444 Carbon Steel Tubes for General Structural Purposes

JIS G3445 Carbon Steel Tubes for Machine Structural Purposes

DIN 2391 Seamless Precision Steel Tubes

EN10305 Steel Tubes for Precision Applications-Technical Delivery Conditions- Part 4: Seamless Cold Drawn Tubes

EN 10210:Seamless Structural Steel Pipes

Technical Specification

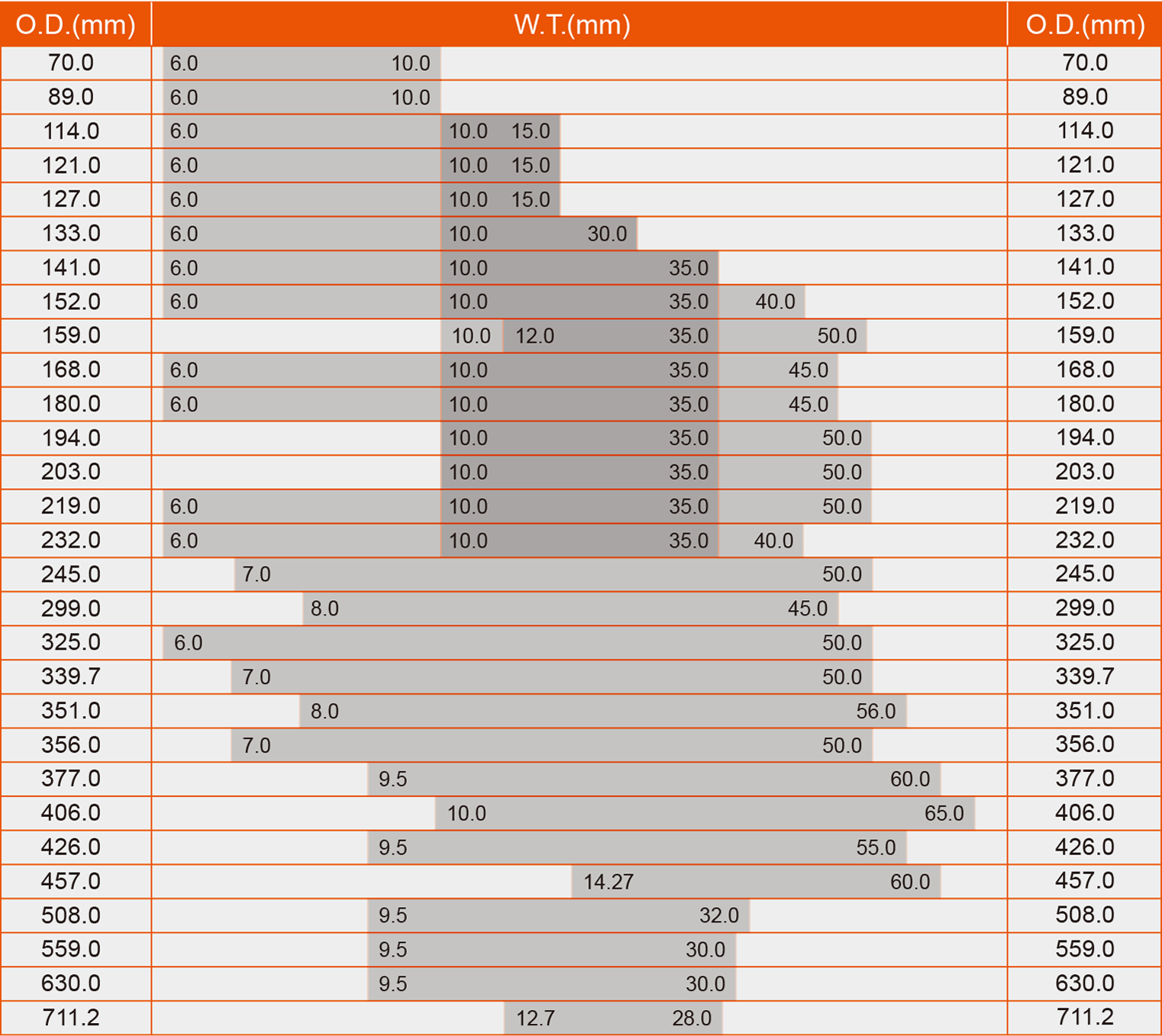

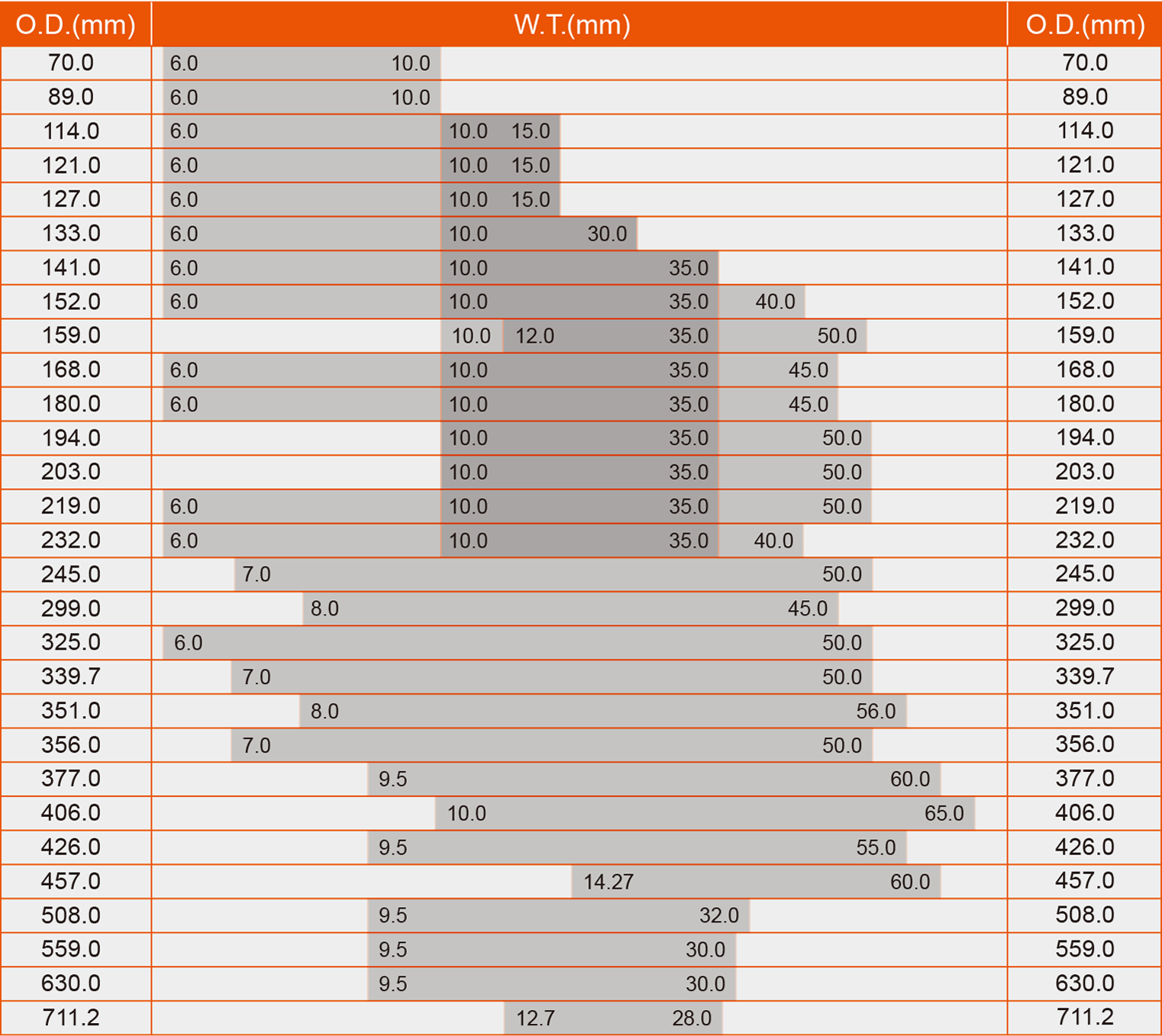

Outer Diameter Size: 1″-24″

Wall Thickness: up to 4″

Standards & Grades

SA-106 Grade B/C

SA-335 P5, P9, P11, P22, P91

SA-333 Grade 1/6

SA-213 T5, T9, T11, T22, T91

API 5LB & X-Grades through X-80

SA-53 Grade B

A-519 1020/1026

A-513 Type 5 (DOM)

Steel Grade

ASTM A 53: Grade A, Grade B, Grade C, Type F, Type E

ASTM A519: 1010-1045, 4130-4142, 5135

GB/T8162: 10, 20, 35, 45, 16Mn, 12CrMo, 15CrMo, 12Cr1 MoV

JIS G3441: SCM 415 TK, SCM 418 TK, SCM 420 TK, SCM 430 TK, SCM 435 TK, SCM 440 TK

JIS G3444: STKM 11A, STKM 12, STKM 13, STKM 14, STKM 15, STKM 16, STKM 17, STKM 18, STKM 19, STKM 20

DIN 2391: St30Si, St30A1, St35, St45, St52

EN10305: E235, E355

EN 10210: S235JRH, S275J0H, S275J2H;, S355J0H, S355J2H; S275NH, S355NH, S275NLH, S355NLH

MECHANICAL SEAMLESS TUBE PROCESSES

PIERCING (ROTARY FORGING)

Piercing a seamless steel tube is a forging operation in which the metal is worked from the inside as well as the outside. We convert a solid bar into a hollow shell by displacing material over a mandrel during rotary rolling. This process results in a refined grain structure and uniform grain flow. Subsequent seamless tube processes include elongating to reach the desired wall thickness, rolling to achieve the outside diameter, and rotary sizing to round the tube diameter to your final required dimensions. We monitor these operations to produce a tube with uniform properties from the surface through wall and from one end to the other.

THERMAL TREATMENT

We house multiple thermal treatment facilities that tailor solutions to meet a wide range of customer needs. We also operate two Induction Thermal Treatment Facilities (ITTF), a Continuous Thermal Treatment Facility (CTTF), a Quench Temper Facility (QTF), a Gambrinus Thermal Treat Facility (GTTF) and our newest Advanced-Quench-and-Temper Facility (AQTF) in Canton, Ohio. At these facilities, we provide a diverse range of processing options to meet demanding strength and hardness requirements – regardless of the order size. We continue to develop these facilities, advance our capabilities and broaden our sophistication in thermal treatment offerings so you can rely on TimkenSteel for innovative product designs and proven quality.

TESTING AND FINISHING

Our $50 million intermediate finishing line (IFL) in Canton incorporates the latest technologies and employs lean processes. This significantly eliminates product touches and material movements, helping improve your lead times. Our state-of-the-art finishing processes through the IFL include straightening, water blast scale removal, cutting, ultrasonic testing, eddy current testing, and dimensional gauging. IFL testing capabilities include hardness, strength, and toughness and cleanness testing in order to meet your specifications.

ASTM A519 Mechanical Engineering Pipe

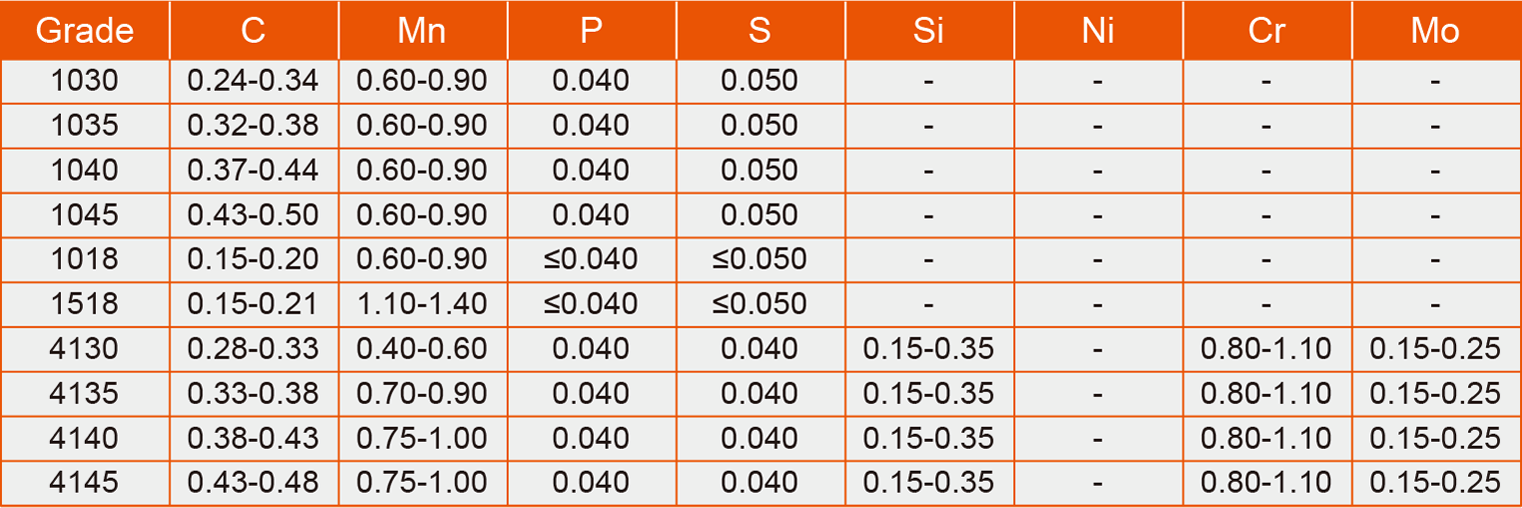

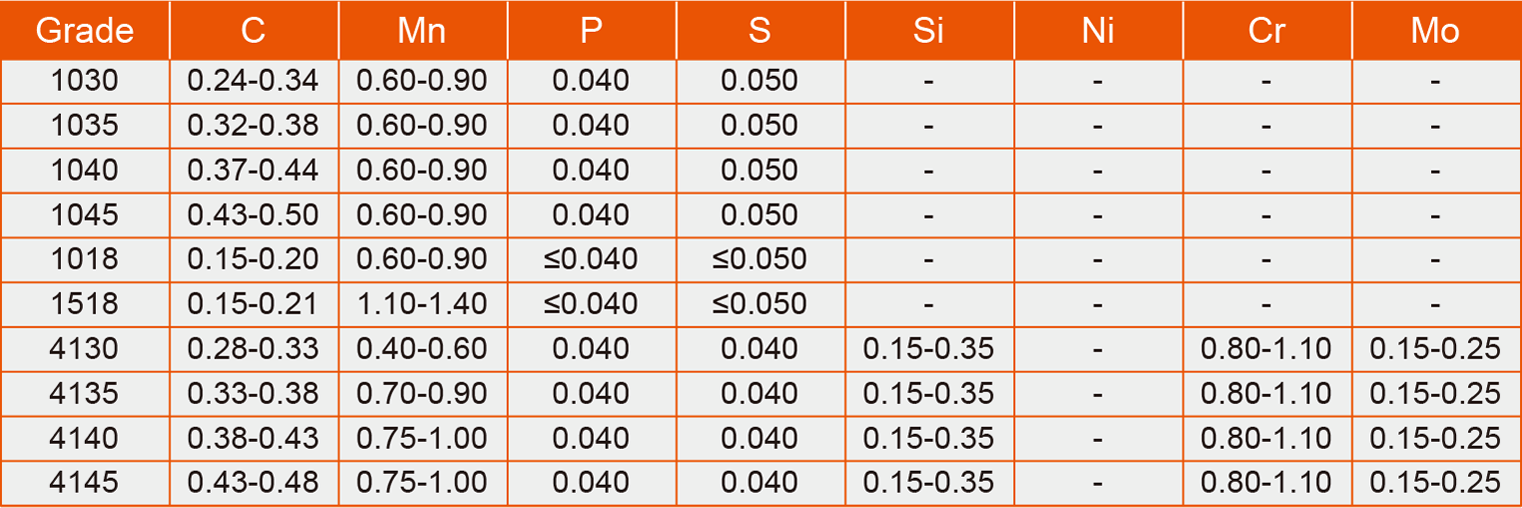

Chemical composition limits(%) as per ASTM A519

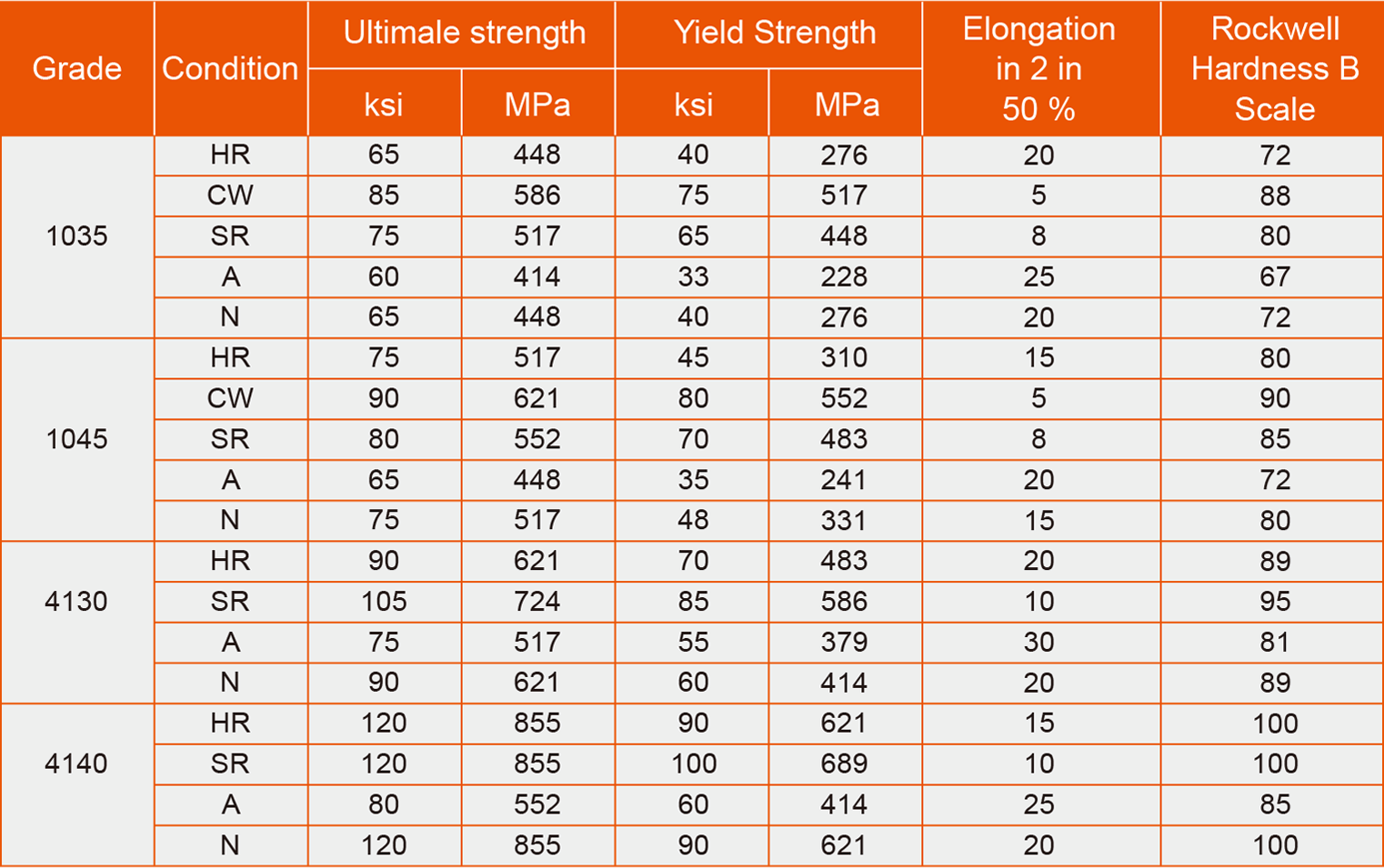

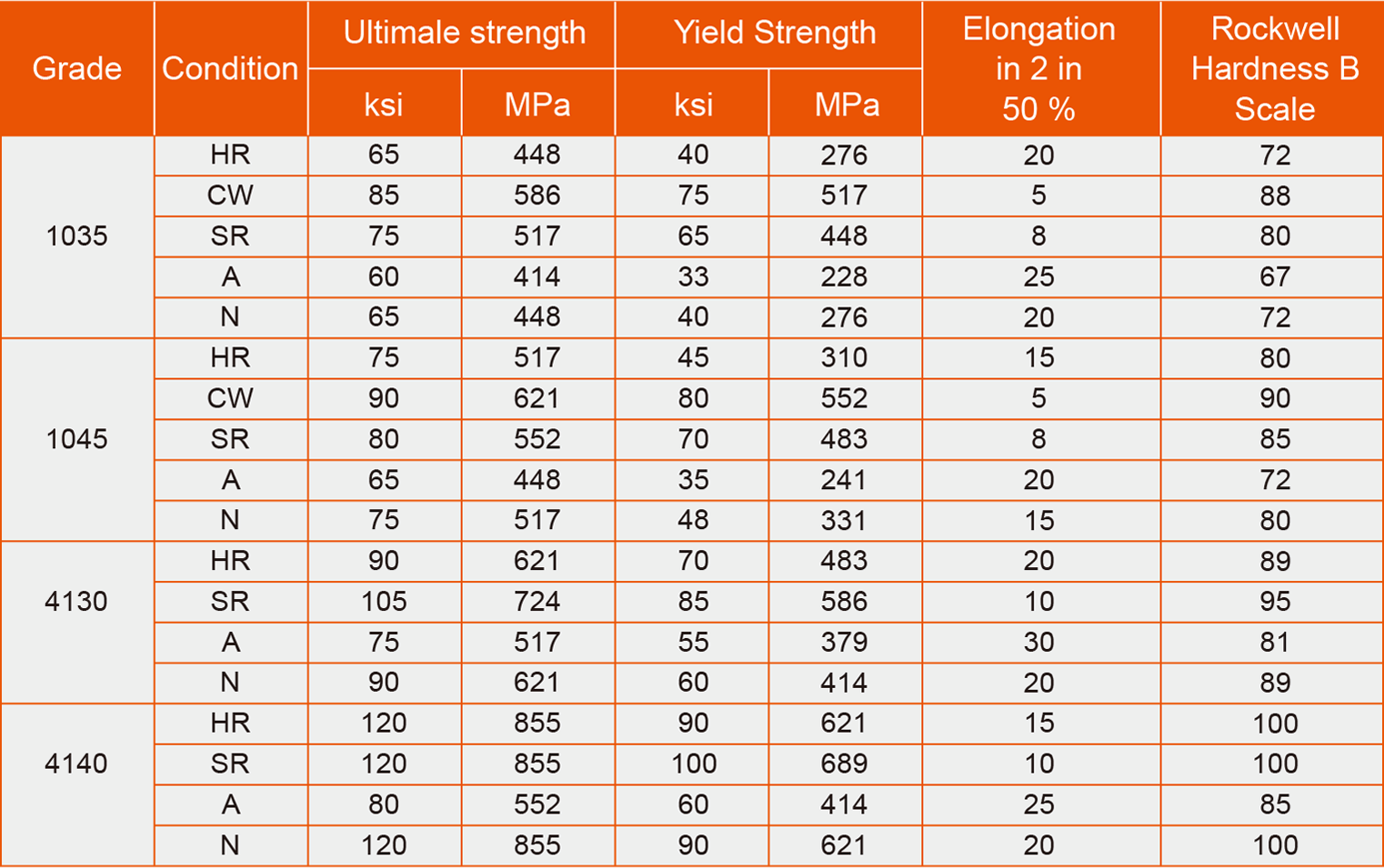

Typical properties for some common carbon and alloy steels

Related Posts

Mechanical Steel Tubes

Mechanical steel tubes are essential for a variety of industrial applications requiring high strength, precision, and durability. The choice of material—whether carbon steel, alloy steel, or stainless steel—depends on the specific requirements of the application, such as mechanical properties, corrosion resistance, and ease of machining.