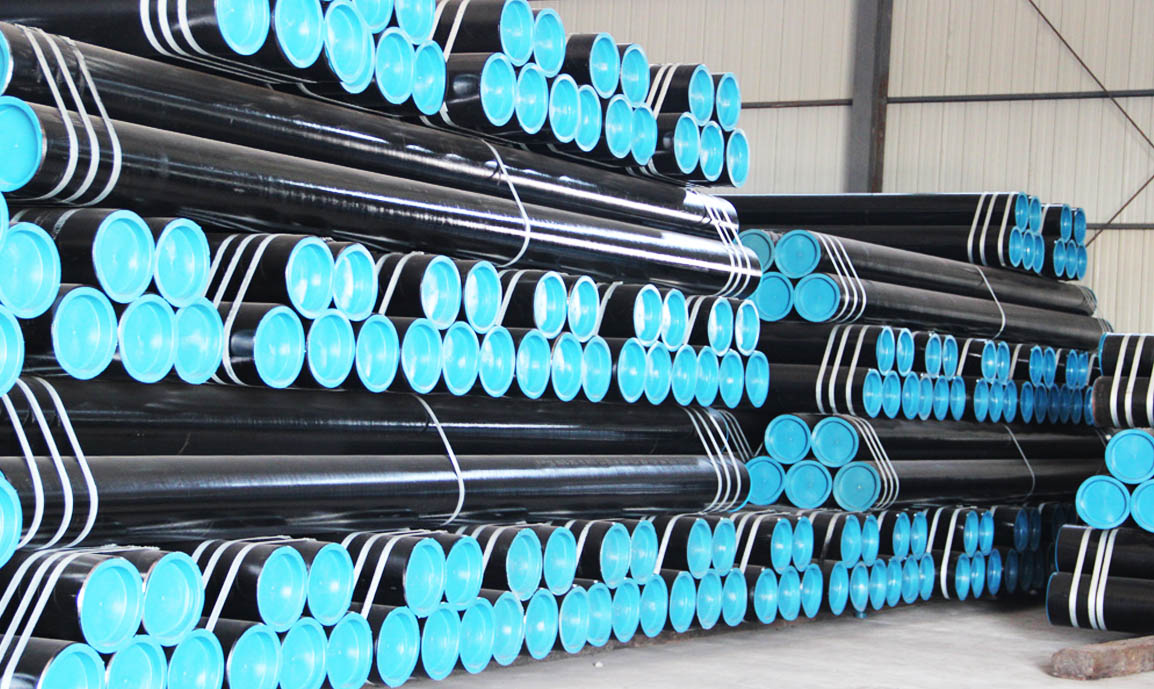

Seamless Pipes

Discover the Excellence of Seamless Steel Pipes from Our Factory

Specifications Range

Our seamless steel pipes are designed to meet a wide range of industrial requirements, offering exceptional performance and reliability. Here’s a snapshot of our specifications:

- Outer Diameter: 1/4 inch – 36 inch

- Wall Thickness: 1.25 mm – 50 mm

- Length: 3.0m – 18m

Types of Seamless Carbon Steel Pipe from Our Factory

We provide a variety of seamless carbon steel pipes tailored for different applications:

- Structure Purposes: Ideal for general structural and mechanical uses.

- Liquid Services: Perfect for conveying petroleum, gas, and other fluids.

- Low and Medium Pressure: Suitable for steam and boiler manufacturing.

- Hydraulic Pillar Service: Designed for hydraulic support applications.

- Auto Semi-shaft Casing: Used in auto semi-shaft casing.

- Line Pipe: Essential for oil and gas conveying.

- Tubing and Casing: Used in the oil and gas industry for conveying purposes.

- Drill Pipes: Integral for well drilling operations.

- Geological Drilling Pipes: Used in geological drilling.

- Petroleum Cracking Tubes: Essential for furnace tubes, heat exchangers.

Chemical Composition and Mechanical Properties

| standard | Grade | Chemical Components (%) | Mechanical Properties | |||||

| C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | ||

| ASTM A53 | A | ≤0.25 | – | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | ≥205 |

| B | ≤0.30 | – | ≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ≥240 | |

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | ≥240 |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ≥275 | |

| ASTM A179 | A179 | 0.06-0.18 | – | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 |

| ASTM A192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 |

| API 5L PSL1 | A | 0.22 | – | 0.9 | 0.03 | 0.03 | ≥331 | ≥207 |

| B | 0.28 | – | 1.2 | 0.03 | 0.03 | ≥414 | ≥241 | |

| X42 | 0.28 | – | 1.3 | 0.03 | 0.03 | ≥414 | ≥290 | |

| X46 | 0.28 | – | 1.4 | 0.03 | 0.03 | ≥434 | ≥317 | |

| X52 | 0.28 | – | 1.4 | 0.03 | 0.03 | ≥455 | ≥359 | |

| X56 | 0.28 | – | 1.4 | 0.03 | 0.03 | ≥490 | ≥386 | |

| X60 | 0.28 | – | 1.4 | 0.03 | 0.03 | ≥517 | ≥448 | |

| X65 | 0.28 | – | 1.4 | 0.03 | 0.03 | ≥531 | ≥448 | |

| X70 | 0.28 | – | 1.4 | 0.03 | 0.03 | ≥565 | ≥483 | |

| API 5L PSL2 | B | 0.24 | – | 1.2 | 0.025 | 0.015 | ≥414 | ≥241 |

| X42 | 0.24 | – | 1.3 | 0.025 | 0.015 | ≥414 | ≥290 | |

| X46 | 0.24 | – | 1.4 | 0.025 | 0.015 | ≥434 | ≥317 | |

| X52 | 0.24 | – | 1.4 | 0.025 | 0.015 | ≥455 | ≥359 | |

| X56 | 0.24 | – | 1.4 | 0.025 | 0.015 | ≥490 | ≥386 | |

| X60 | 0.24 | – | 1.4 | 0.025 | 0.015 | ≥517 | ≥414 | |

| X65 | 0.24 | – | 1.4 | 0.025 | 0.015 | ≥531 | ≥448 | |

| X70 | 0.24 | – | 1.4 | 0.025 | 0.015 | ≥565 | ≥483 | |

| X80 | 0.24 | – | 1.4 | 0.025 | 0.015 | ≥621 | ≥552 | |

Standards and Applications

Our seamless steel pipes adhere to various international standards, ensuring quality and reliability across different applications:

- API Standards:

- API 5L: Line pipe for pipeline transportation systems.

- API 5CT: Tubing and casing for wells.

- API 5DP: Drill pipe for well drilling.

- ASTM Standards:

- ASTM A53: Used as structural steel or for low-pressure plumbing.

- ASTM A106: Seamless carbon steel pipe for high-temperature service.

- ASTM A335: Seamless ferritic alloy-steel pipe for high-temperature service.

- ASTM A213: Seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes.

- ASTM A179: Seamless cold-drawn low-carbon steel heat-exchanger and condenser tubes.

- ASTM A192: Seamless carbon steel boiler tubes for high-pressure service.

- ASTM A210: Seamless medium-carbon steel boiler and superheater tubes.

- ASTM A333: Seamless steel pipe for low-temperature service and other applications requiring notch toughness.

- ASTM A519: Seamless carbon and alloy steel mechanical tubing.

- ASTM A252: Seamless and welded steel pipe piles.

- DIN Standards:

- DIN 17175: For heat-resistant seamless steel pipe lines.

- DIN 1629: For seamless circular tubes of non-alloy steels with special quality requirements.

- DIN 2391: For cold-drawn or cold-rolled precision seamless steel tubes.

- JIS Standards:

- JIS G3454: Seamless carbon steel pipe for pressure service.

- JIS G3456: Seamless carbon steel pipe for high-temperature service.

- JIS G3461: Seamless carbon steel pipe for boiler and heat exchanger.

- EN Standards:

- EN 10210: For hot-finished seamless structural hollow sections of non-alloy steels.

- EN 10216: Seamless steel tubes for pressure purposes.

- BS Standards:

- BS 3059: For carbon, alloy, and austenitic stainless steel tubes with specified elevated temperature properties.

Dimension Tolerances of Seamless Carbon Steel Pipe

Our seamless carbon steel pipes are manufactured with precise dimension tolerances to ensure high quality and performance:

- Hot Rolled Pipes:

- Outer Diameter (OD):

- < 50 mm: ±0.50 mm

- ≥ 50 mm: ±1%

- Wall Thickness (WT):

- < 4 mm: ±12.5%

- 4 – 20 mm: +15%, -12.5%

- 20 mm: ±12.5%

- Outer Diameter (OD):

- Cold Drawn Pipes:

- Outer Diameter (OD):

- 6 – 10 mm: ±0.20 mm

- 10 – 30 mm: ±0.40 mm

- 30 – 50 mm: ±0.45 mm

- 50 mm: ±1%

- Wall Thickness (WT):

- < 1 mm: ±0.15 mm

- 1 – 3 mm: ++ 15%, – 10%

- >3mm + 12.5%, – 10%

- Outer Diameter (OD):

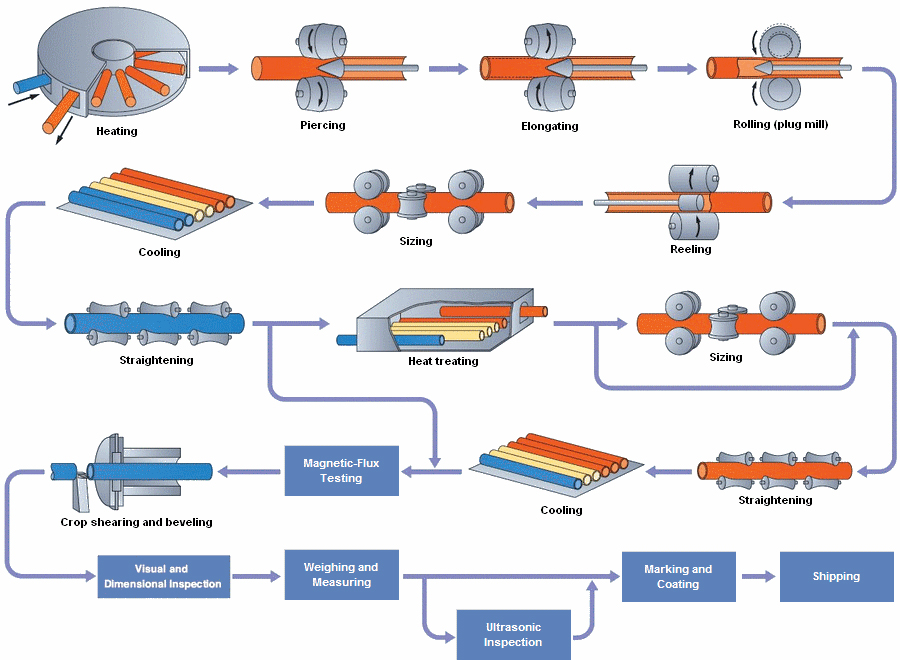

Process

Specification

| NOMINAL PIPE SIZE | OD

(mm) |

NOMINAL WALL THICKNESS |

|||||||||||||

| DN | NB(inch) | ASME | SCH10 | SCH20 | SCH30 | STD | SCH40 | SCH60 | XS | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | XXS |

| 15 | 1/2″ | 21.3 | 2.11 | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | |||||

| 20 | 3/4″ | 26.7 | 2.11 | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | |||||

| 25 | 1″ | 33.4 | 2.77 | 2.9 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | |||||

| 32 | 1.1/4″ | 42.2 | 2.77 | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.7 | |||||

| 40 | 1.1/2″ | 48.3 | 2.77 | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | |||||

| 50 | 2″ | 60.3 | 2.77 | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | |||||

| 65 | 2.1/2″ | 73 | 3.05 | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | |||||

| 80 | 3″ | 88.9 | 3.05 | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.25 | |||||

| 90 | 3.1/2″ | 101.6 | 3.05 | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 | |||||||

| 100 | 4″ | 114.3 | 3.05 | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | ||||

| 125 | 5″ | 141.3 | 3.4 | 6.55 | 6.55 | 9.53 | 9.53 | 12.7 | 15.88 | 19.05 | |||||

| 150 | 6″ | 168.3 | 3.4 | 7.11 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8″ | 219.1 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 250 | 10″ | 273 | 4.19 | 6.35 | 7.8 | 9.27 | 9.27 | 12.7 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 |

| 300 | 12″ | 323.8 | 4.57 | 6.35 | 8.38 | 9.53 | 10.31 | 14.27 | 12.7 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 |

| 350 | 14″ | 355.6 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.7 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16″ | 406.4 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | 16.66 | 12.7 | 21.44 | 26.19 | 30.96 | 36.53 | 40.19 | |

| 450 | 18″ | 457.2 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.7 | 23.83 | 39.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20″ | 508 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 20.62 | 12.7 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | |

| 550 | 22″ | 558.8 | 6.35 | 9.53 | 12.7 | 9.53 | 22.23 | 12.7 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24″ | 609.6 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.7 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26″ | 660.4 | 7.92 | 12.7 | 9.53 | 12.7 | |||||||||

| 700 | 28″ | 711.2 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 750 | 30″ | 762 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 800 | 32″ | 812.8 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | 12.7 | |||||||

| 850 | 34″ | 863.6 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | 12.7 | |||||||

| 900 | 36″ | 914.4 | 7.92 | 12.7 | 15.88 | 9.53 | 19.05 | 12.7 | |||||||