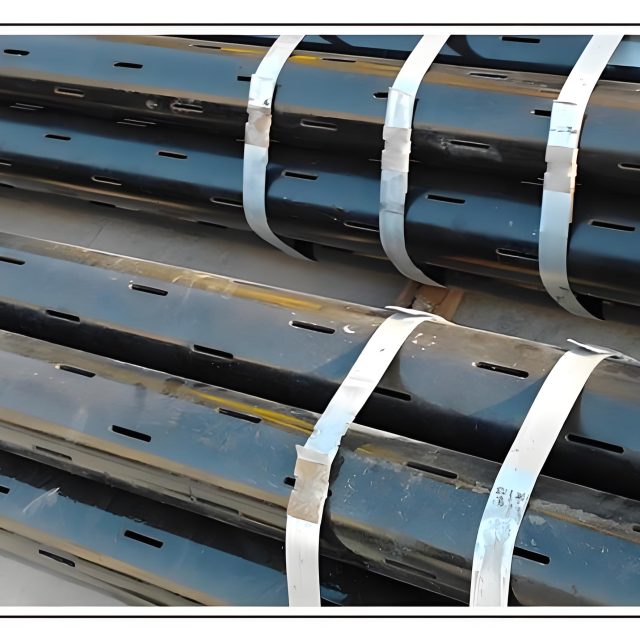

Slotted Liner Casing Pipe

Detailed Specifications of Slotted Liner Casing Pipe

Slotted liner casing pipes are essential for sand control and wellbore stability in various industries. Below, we delve into the key specifications and dimensions, including slot size, slotting patterns, slot types, slot density, and overall dimensions.

Slot Size of Slotted Liner

The slot size is a critical factor in determining the effectiveness of sand control and fluid flow in slotted liners. Slot sizes can be customized based on specific well conditions and requirements.

- Width: Typically ranges from 0.012 inches to 0.25 inches.

- Length: Commonly varies from 1 inch to 6 inches.

The slot size of the slotted liner, which includes the width and length of the slot, is customized to the customer’s specifications. The minimum slot width for straight or keystone slots is 0.012 inches, and the maximum slot width is 0.25 inches.

| 1.5 Inch Long | 2.0 to 2.5 Inch Long | 2.5 Inch Long |

|---|---|---|

| 0.012 inch wide | 0.024 inch wide | 0.078 inch wide |

| 0.015 inch wide | 0.025 inch wide | 0.125 inch wide |

| 0.016 inch wide | 0.038 inch wide | 0.250 inch wide |

| 0.018 inch wide | 0.048 inch wide | – |

| – | 0.058 inch wide | – |

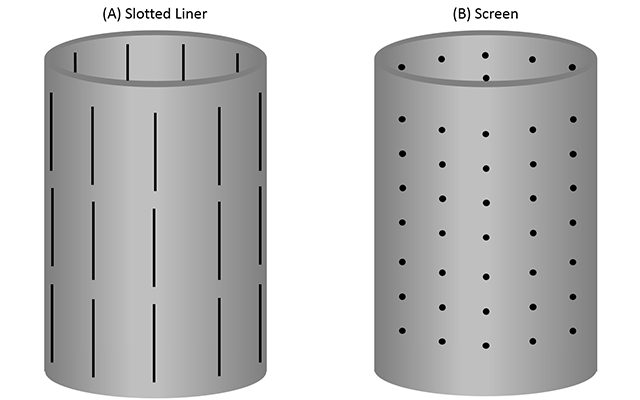

Slotting Patterns of Slotted Liner

The slotting pattern refers to the arrangement of slots around the circumference and along the length of the liner. The pattern affects the flow characteristics and structural integrity of the liner.

- Straight Pattern: Slots are aligned in straight rows along the length of the liner.

- Staggered Pattern: Slots are offset in adjacent rows, providing a more uniform distribution.

- Spiral Pattern: Slots are arranged in a helical pattern around the liner, often used to enhance fluid flow and reduce clogging.

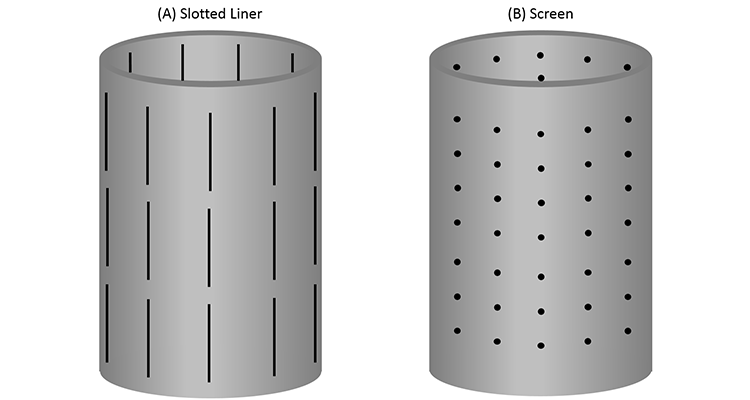

Three distinct slot layouts have been created to accommodate distinct traits (shown below). In comparison to staggered and straight slot patterns, the gang slot design significantly improves the liner’s resistance to lateral buckling and collapse stresses.

Staggered Slotted Liner

Staggered slots are evenly distributed around the circumference with an offset.

Gang Slotted Liner

Gang slots are made up of many slots that are dispersed around the perimeter.

Straight Slotted Liner

Straight slotted liner features slot columns spaced evenly around the circumference without offset.

Slot Types of Slotted Liner

Different slot types can be employed depending on the intended application and the expected environmental conditions.

- Straight Slots: Simple, linear slots that are easy to manufacture and provide good flow characteristics.

- Keystone Slots: Wider at the outer surface and narrower at the inner surface, these slots help prevent clogging by allowing particles to pass through more easily.

- Chevron Slots: V-shaped slots that enhance structural strength and flow distribution.

– Straight Slots

This slot type is cut perpendicular to the liner and has the same diameter from the inside to the outside of the wall. While straight slots are less expensive to build, they are less effective in containing sand than keystone slots.

– Keystone Slots

Keystone slots, or tapered slots, are cut at a little angle and are larger on the inside than on the outside, ensuring that any particle entering the slot can pass freely without clogging it.

While keystone slots are more expensive to manufacture than straight slots, they eliminate the danger of production losses caused by filled liner slots.

Slot Density

Slot density refers to the number of slots per unit length of the liner, which influences the total open area and the flow capacity of the liner.

- Low Density: Fewer slots per unit length, used where higher structural strength is required.

- Medium Density: A balanced number of slots, providing a good compromise between flow capacity and structural integrity.

- High Density: A higher number of slots per unit length, maximizing the open area for fluid flow but potentially reducing structural strength.

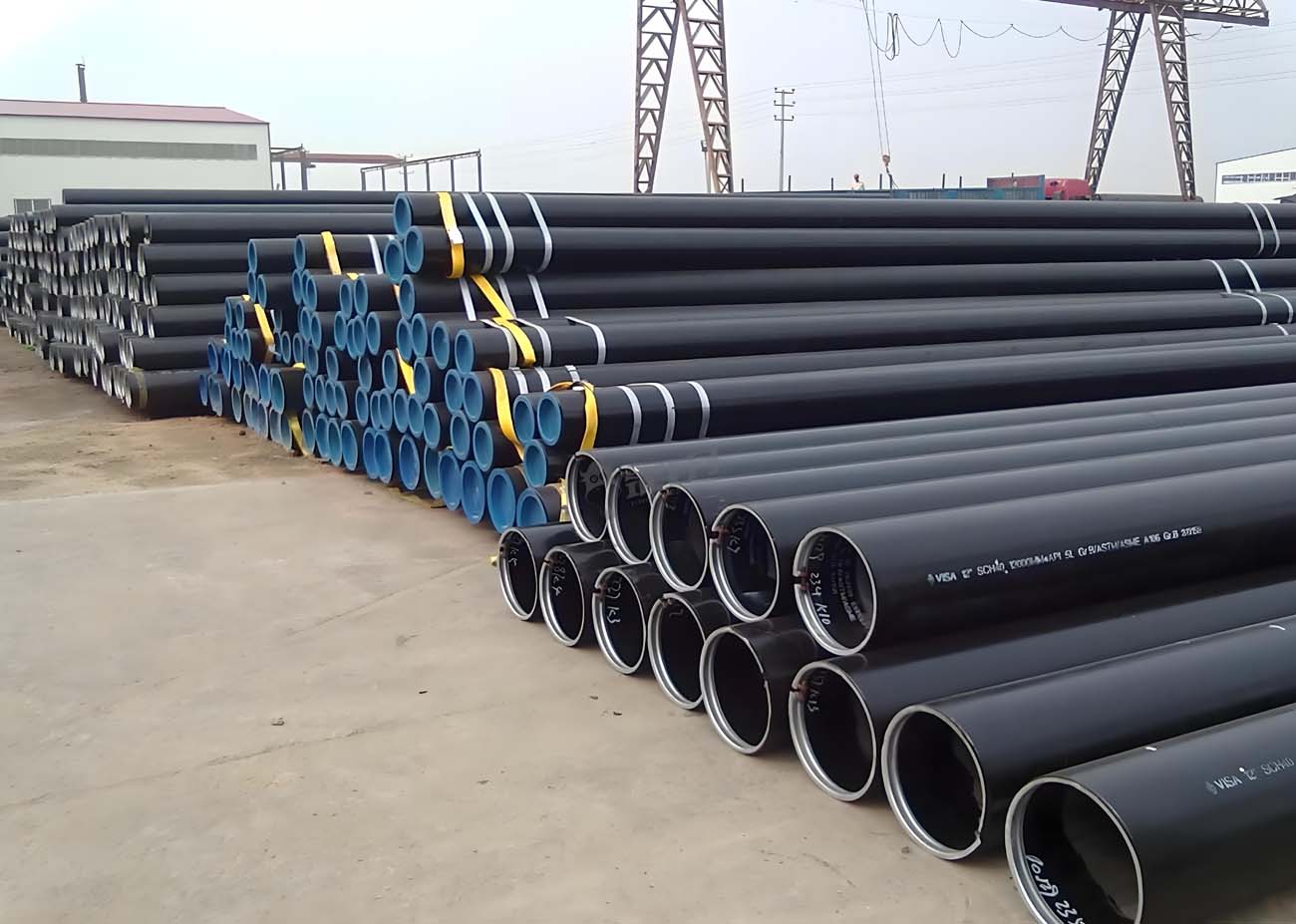

Dimensions and Sizes of Slotted Liner

Slotted liners come in various sizes to fit different wellbore diameters and depths. The dimensions are specified to match standard casing sizes used in the industry.

- Outer Diameter (OD): Common OD sizes range from 4.5 inches to 20 inches.

- Wall Thickness: Typically ranges from 0.25 inches to 0.5 inches, depending on the required strength and durability.

- Length: Standard lengths can range from 20 feet to 40 feet, but custom lengths are also available based on specific needs.

Specification & Size of Casing Slotted Liner

Material Specifications

- Steel Grade: Most common grades include J55, K55, N80, L80, P110, and various grades of stainless steel (304, 316, etc.).

- Coating: Optional coatings such as epoxy or galvanization for enhanced corrosion resistance.

Standard Sizes

| Nominal Diameter (inches) | Outer Diameter (inches) | Wall Thickness (inches) | Length (feet) |

|---|---|---|---|

| 4.5 | 4.5 | 0.25 – 0.375 | 20 – 40 |

| 5.5 | 5.5 | 0.25 – 0.375 | 20 – 40 |

| 7.0 | 7.0 | 0.25 – 0.5 | 20 – 40 |

| 9.625 | 9.625 | 0.25 – 0.5 | 20 – 40 |

| 13.375 | 13.375 | 0.375 – 0.5 | 20 – 40 |

| 20.0 | 20.0 | 0.375 – 0.5 | 20 – 40 |

Manufacturing Standards

- API: API 5CT for casing and tubing.

- ISO: ISO 11960 for petroleum and natural gas industries—steel pipes for use as casing or tubing for wells.

- ASTM: Various ASTM standards for material properties and testing.

Continuing from the previous section, let’s delve deeper into the manufacturing standards and additional considerations for selecting and implementing slotted liner casing pipes.

Grades of Casing pipe:

- API 5CT H40

- API 5CT J55

- API 5CT K55

- API 5CT M65

- API 5CT N80 (1,Q)

- API 5CT L80 (9Cr,13Cr)

- API 5CT C90

- API 5CT T95

- API 5CT P110

- API 5CT Q125

Sizes of Casing pipe:

Diameter :from 4 1/2 inch to 20 inch (48.26mm – 508mm)

Nominal Weight: from 9.5 lb/ft to 169 lb/ft, from 9.5 ppf to 169 ppf

Lenght: R1, R2, R3

Manufacturing Standards (Continued)

- API 5CT: This standard specifies the requirements for casing and tubing in the oil and gas industry, including material properties, dimensions, and testing procedures.

- ISO 11960: This international standard provides specifications for steel pipes used as casing or tubing for wells, covering aspects such as material grades, mechanical properties, and dimensional tolerances.

- ASTM Standards: Various ASTM standards apply to the material properties and testing methods for slotted liners, ensuring consistency and reliability in their performance.

Additional Considerations

Corrosion Resistance

In environments where corrosion is a significant concern, such as in high salinity or acidic conditions, it is crucial to select materials with high corrosion resistance. Stainless steel grades like SS304 and SS316 are commonly used for their excellent resistance to corrosion.

Installation Techniques

Proper installation techniques are essential to maximize the effectiveness of slotted liners. This includes ensuring the slots are correctly oriented to optimize fluid flow and prevent clogging. Additionally, centralizers may be used to keep the liner centered within the wellbore, reducing wear and tear.

Compatibility with Other Downhole Equipment

Slotted liners must be compatible with other downhole equipment, such as pumps, packers, and screens. Ensuring compatibility helps avoid operational issues and facilitates smoother well completion and production processes.

Customization Options

Manufacturers often offer customization options to tailor slotted liners to specific well conditions. This includes varying the slot size, pattern, type, and density, as well as selecting appropriate materials and coatings.

Summary Table of Specifications

Here is a summary table that consolidates the key specifications discussed:

| Specification | Details |

|---|---|

| Slot Size | Width: 0.012″ – 0.25″, Length: 1″ – 6″ |

| Slotting Patterns | Straight, Staggered, Spiral |

| Slot Types | Straight, Keystone, Chevron |

| Slot Density | Low, Medium, High |

| Outer Diameter (OD) | 4.5″ – 20″ |

| Wall Thickness | 0.25″ – 0.5″ |

| Length | 20′ – 40′, custom lengths available |

| Material | J55, K55, N80, L80, P110, SS304, SS316 |

| Coating | Optional epoxy, galvanization |

| Standards | API 5CT, ISO 11960, various ASTM standards |

| Corrosion Resistance | High-grade materials like SS304, SS316 for corrosive environments |

| Installation | Proper orientation, use of centralizers, compatibility with other downhole equipment |

| Customization | Slot size, pattern, type, density, material selection, coatings |

Slotted liner casing pipes play a crucial role in ensuring the efficiency and longevity of wells in various industries, including oil, gas, water, and geothermal. By understanding and selecting the appropriate specifications, operators can significantly improve well performance, manage sand control effectively, and maintain wellbore integrity. Proper material selection, adherence to manufacturing standards, and attention to installation techniques are essential to maximizing the benefits of slotted liner casing pipes.

References

- American Petroleum Institute (API). (2020). Standards for Casing and Tubing.

- International Organization for Standardization (ISO). (2018). ISO 11960: Petroleum and Natural Gas Industries – Steel Pipes for Use as Casing or Tubing for Wells.

- Society of Petroleum Engineers (SPE). (2019). Advances in Sand Control Technology.

- Water Well Journal. (2021). Best Practices for Well Design and Construction.

- Journal of Geothermal Energy. (2022). Innovations in Geothermal Well Design.