SSAW Steel Pipe

SSAW Steel Pipe: An Overview

SSAW (Spiral Submerged Arc Welding) steel pipes are manufactured by coiling a skelp (a long strip of metal) and welding it both internally and externally to create a spiral seam. This method is particularly effective for producing large diameter and long length pipes. SSAW pipes are mainly used in fluid transportation, construction, piling, oil and gas, and as water pipeline systems.Spiral Welded Pipes, commonly referred to as SSAW (Spiral Submerged Arc Welded) pipes, are manufactured by winding a steel strip into a spiral and welding the seam both internally and externally. This method allows for large diameter pipes suitable for various applications, including transportation of fluids, structural applications, and construction projects.

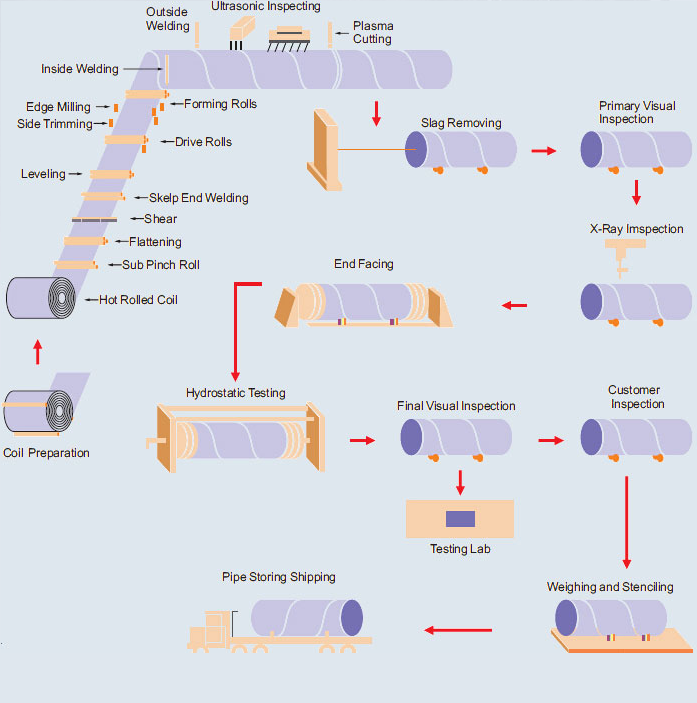

SSAW Manufacturing Process

- Steel Coil Preparation: High-quality steel coils are selected and prepared.

- Edge Preparation: Edges of the steel coils are trimmed and beveled to ensure proper weld seam.

- Forming: Steel coils are fed into a spiral forming machine where they are formed into a spiral shape.

- Tack Welding: The edges of the spirally formed pipe are tack-welded to hold the shape.

- Submerged Arc Welding: The spiral seam is welded using submerged arc welding both internally and externally, ensuring deep penetration and strong weld integrity.

- Inspection: Pipes undergo various non-destructive tests such as ultrasonic testing, radiographic testing, and visual inspection to ensure weld quality and pipe integrity.

- Hydrostatic Testing: Each pipe is subjected to hydrostatic pressure testing to verify its pressure resistance.

- Finishing: Final processes include end beveling, coating, and marking as per customer specifications.

Advantages of SSAW Steel Pipes

- Cost-Effective: Generally, SSAW pipes are more cost-effective than LSAW pipes, especially for large diameter pipes.

- Versatile Applications: They are suitable for a wide range of applications, particularly where specifications require longer lengths than those that can be achieved by other types of pipes.

- High Strength: Due to the spiral weld, SSAW pipes exhibit high strength and durability, suitable for high-pressure applications.

Disadvantages of SSAW Steel Pipes

- Potential for Defects: The spiral weld, while strong, can be a site for defects if not manufactured correctly. Potential issues include incomplete fusion, porosity, and cracks.

- Limited Precision and Tolerances: Compared to LSAW and seamless pipes, SSAW pipes might not have as tight dimensional tolerances, affecting their suitability for certain precision-required applications.

Applications of SSAW Steel Pipes

- Water and Wastewater Transport: Used in the construction of pipelines for transferring water and other fluids.

- Oil and Gas Industry: Suitable for the transmission of oil and natural gas.

- Structural Applications: Employed in the construction of structures and piling due to their high strength and flexibility in size.

- Construction Field: Used widely in construction projects, including bridges and buildings for structural supports.

Standards Compliance

Here’s a detailed breakdown of the specifications for Spiral Welded Pipes: SSAW pipes are produced according to a variety of standards, ensuring their suitability for different industrial and structural applications. Key standards include:

- API 5L: Pipeline applications, mainly in the oil and gas industry.

- API 5CT: Casing and tubing applications for the petroleum and natural gas industry.

- ASTM A53: Typically specified for pipeline and casing in the construction, and oil and gas industries.

- ASTM A500: Structural applications such as building and infrastructure construction.

- ASTM A795: Fire protection systems.

- AS 1163: Structural steel hollow sections.

- EN 10217: Pressure purposes.

- EN 1029: Non-alloy steel tubes.

- JIS G3444: General structural purposes.

- JIS G 3452: Piping for ordinary piping.

- BS 1387: Connecting to threaded pipe in firefighting systems and other applications.

Material Grades

These pipes come in various material grades, each tailored for specific applications and environmental conditions:

- GR.A, GR.B: Common grades used in many applications including low-pressure conveyance of water, air, and other gases.

- GR.1, GR.2, GR.3: Typically higher strength grades for more demanding applications.

- X42, X46, X52, X56, X60, X70: High-grade steels used in high-pressure environments such as oil and gas pipelines.

- Q235, Q345: Common structural steel grades in China, similar to US ASTM grades.

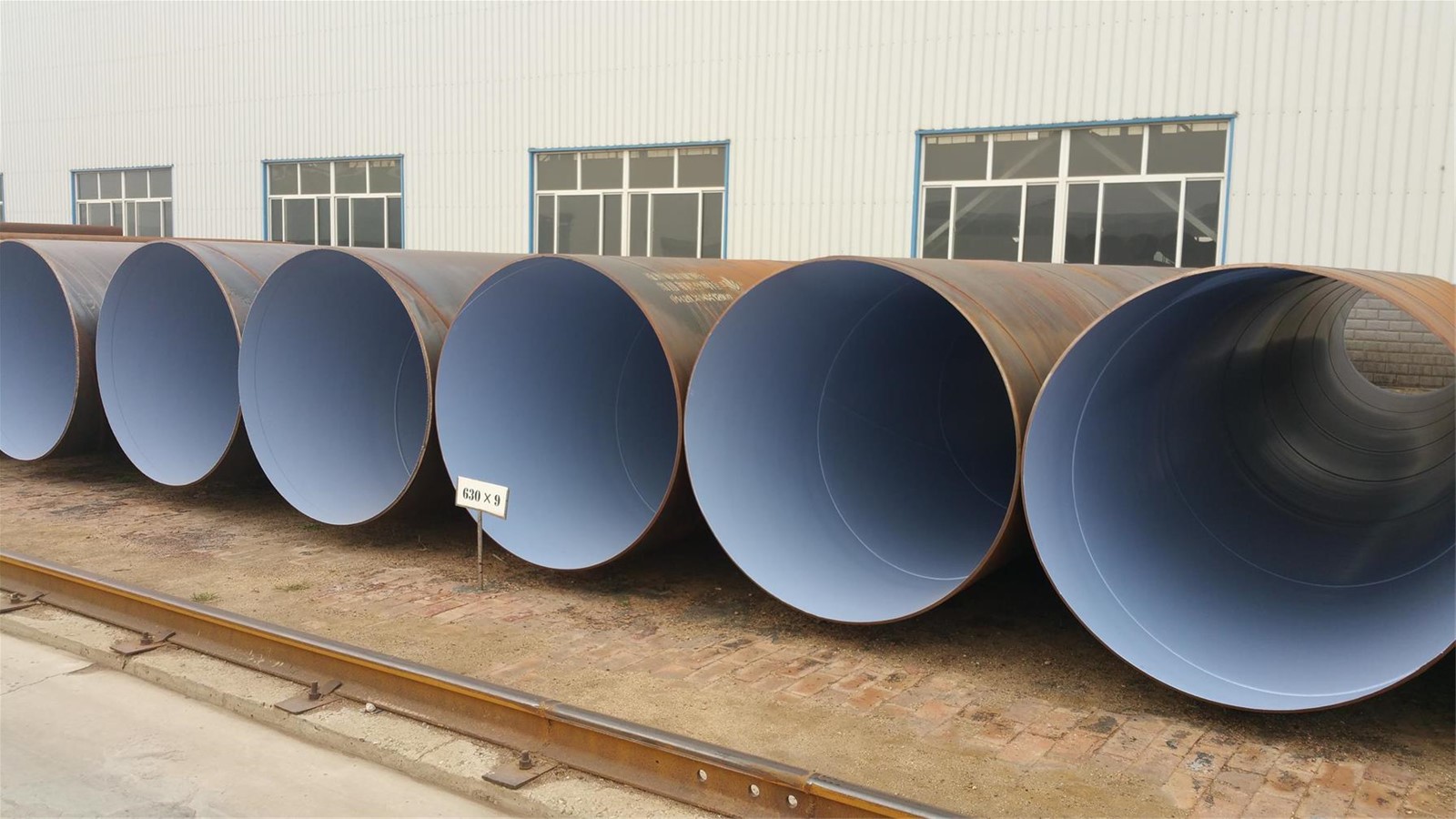

Dimensions

- Outer Diameter: Ranges from 8 inches to 80 inches (219.1mm to 2032mm, DN200 to DN2000), accommodating a wide range of installation requirements.

- Thickness: Varies from 6mm to 25.4mm, available in schedules from SCH 20 to SCH XXS, which allows for application in both low-pressure and high-pressure environments.

- Length: Typically between 3 meters and 18 meters, facilitating both transportability and adaptability to project-specific requirements.

Specification

| Out Diameter | Wall Thickness (mm) | |||||||||||||||||||

| mm | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 219.1 | . | . | . | . | ||||||||||||||||

| 273 | . | . | . | . | . | |||||||||||||||

| 323.9 | . | . | . | . | . | . | . | |||||||||||||

| 325 | . | . | . | . | . | . | . | |||||||||||||

| 355.6 | . | . | . | . | . | . | . | |||||||||||||

| 377 | . | . | . | . | . | . | . | . | ||||||||||||

| 406.4 | . | . | . | . | . | . | . | |||||||||||||

| 426 | . | . | . | . | . | . | . | |||||||||||||

| 457 | . | . | . | . | . | . | . | |||||||||||||

| 478 | . | . | . | . | . | . | . | |||||||||||||

| 508 | . | . | . | . | . | . | . | . | ||||||||||||

| 529 | . | . | . | . | . | . | . | . | ||||||||||||

| 630 | . | . | . | . | . | . | . | . | . | |||||||||||

| 711 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

| 720 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

| 813 | . | . | . | . | . | . | . | . | . | . | . | . | ||||||||

| 820 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

| 920 | . | . | . | . | . | . | . | . | . | . | ||||||||||

| 1020 | . | . | . | . | . | . | . | . | . | . | . | . | . | |||||||

| 1220 | . | . | . | . | . | . | . | . | . | . | . | . | . | |||||||

| 1420 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

| 1620 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

| 1820 | . | . | . | . | . | . | . | . | . | . | ||||||||||

| 2020 | . | . | . | . | . | . | . | . | . | |||||||||||

| 2220 | . | . | . | . | . | . | . | . | ||||||||||||

| 2500 | . | . | . | . | . | . | . | . | . | . | . | . | . | |||||||

| 2540 | . | . | . | . | . | . | . | . | . | . | . | . | ||||||||

| 3500 | . | . | . | . | . | . | . | . | . | . | ||||||||||

Surface Coating and Protection

- Options include varnishing, oiling, and advanced coatings like Hot Dip Galvanizing, FBE (Fusion Bonded Epoxy), 2PP (two-layer polypropylene), 3PP (three-layer polypropylene), 2PE (two-layer polyethylene), and 3PE (three-layer polyethylene). These coatings enhance the pipe’s resistance to corrosion and wear.

End Types and Joint Methods

- End Types: Available as plain, bevelled, threaded, or grooved, which are crucial for forming connections in the pipeline.

- Joint Methods: Include fitting, flange, coupling, clamp, pipe shoulder, and welding options, providing flexibility in pipeline design and installation.

Pipe Machining Options

- Operations such as welding, bending, hole drilling, punching, swaging, tapering, flaring, and expanding allow customization of pipes for specific applications and installations.

Conclusion

Spiral Welded Pipes are designed to meet a diverse range of application needs from oil and gas pipelines to water transportation and structural applications. The comprehensive range of standards, grades, dimensions, and additional processing options ensure that these pipes can be tailored to meet specific operational and environmental demands. When selecting a spiral welded pipe, it’s crucial to consider the specific requirements of your project to choose the appropriate specifications and treatments.

Sizes:

Out diameter:219mm-3620mm

Wall thickness: 5mm-25.4mm

Length: 3m-12m

Standard

| Classfication | Standard | Main Products |

| Steel Pipe for Fluid Service | GB/T 14291 | Welded pipe for mine fluid sevice |

| GB/T 3091 | Welded pipe for low pressure fluid service | |

| SY/T 5037 | Spirally submerged arc welded steel pipe for pipelines for low pressure fluid service | |

| ASTM A53 | Black and hot-hipped galvanized welded and seamless steel pipe | |

| BS EN10217-2 | Welded steel tybes for pressure purposes – delivery technical conditions – part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties | |

| BS EN10217-5 | Welded steel tybes for pressure purposes – delivery technical conditions – part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties | |

| Steel Pipe for Ordinary Structure | GB/T 13793 | Longitudinally electric resistance welded steel pipe |

| SY/T 5040 | Spirally submerged arc welded steel pipe piles | |

| ASTM A252 | Welded and seamless steel pipe piles | |

| BS EN10219-1 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivert conditions | |

| BS EN10219-2 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part2: tolerances dimmsions and sectional properties | |

| Line Pipe | GB/T 9711.1 | Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) |

| GB/T 9711.2 | Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) | |

| API 5L PSL1/2 | Line pipe | |

| Casing | API 5CT/ ISO 11960 PSL1 | Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries |

Chemical Analysis and Mechanical Properties of SSAW Steel Pipe

| Standard | Grade | Chemical Composition(max)% | Mechanical Properties(min) | |||||

| C | Si | Mn | P | S | Tensile Strength(Mpa) | Yield Strength(Mpa) | ||

| API 5CT | h40 | – | – | – | – | 0.030 | 417 | 417 |

| J55 | – | – | – | – | 0.030 | 517 | 517 | |

| K55 | – | – | – | – | 0.300 | 655 | 655 | |

| API 5L PSL1 | A | 0.22 | – | 0.90 | 0.030 | 0.030 | 335 | 335 |

| B | 0.26 | – | 1.20 | 0.030 | 0.030 | 415 | 415 | |

| X42 | 0.26 | – | 1.30 | 0.030 | 0.030 | 415 | 415 | |

| X46 | 0.26 | – | 1.40 | 0.030 | 0.030 | 435 | 435 | |

| X52 | 0.26 | – | 1.40 | 0.030 | 0.030 | 460 | 460 | |

| X56 | 0.26 | – | 1.40 | 0.030 | 0.030 | 490 | 490 | |

| X60 | 0.26 | – | 1.40 | 0.030 | 0.030 | 520 | 520 | |

| X65 | 0.26 | – | 1.45 | 0.030 | 0.030 | 535 | 535 | |

| X70 | 0.26 | – | 1.65 | 0.030 | 0.030 | 570 | 570 | |

| API 5L PSL2 | B | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 415 | 415 |

| X42 | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 415 | 415 | |

| X46 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 435 | 435 | |

| X52 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 460 | 460 | |

| X56 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 490 | 490 | |

| X60 | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 520 | 520 | |

| X65 | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 535 | 535 | |

| X70 | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 | 570 | 570 | |

| X80 | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 | 625 | 625 | |

| ASTM A53 | A | 0.25 | 0.10 | 0.95 | 0.050 | 0.045 | 330 | 330 |

| B | 0.30 | 0.10 | 1.20 | 0.050 | 0.045 | 415 | 415 | |

| ASTM A252 | 1 | – | – | – | 0.050 | – | 345 | 345 |

| 2 | – | – | – | 0.050 | – | 414 | 414 | |

| 3 | – | – | – | 0.050 | – | 455 | 455 | |

| EN10217-1 | P195TR1 | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P195TR2 | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 | |

| P235TR1 | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P235TR2 | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P265TR1 | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| P265TR2 | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10217-2 | P195GH | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P235GH | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P265GH | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10217-5 | P235GH | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 |

| P265GH | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10219-1 | S235JRH | 0.17 | – | 1.40 | 0.040 | 0.040 | 360 | 360 |

| S275JOH | 0.20 | – | 1.50 | 0.035 | 0.035 | 410 | 410 | |

| S275J2H | 0.20 | – | 1.50 | 0.030 | 0.030 | 410 | 410 | |

| S355JOH | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 470 | 470 | |

| S355J2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | 470 | 470 | |

| S355K2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | 470 | 470 | |

Packing

According to the regulations and customer’s requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.